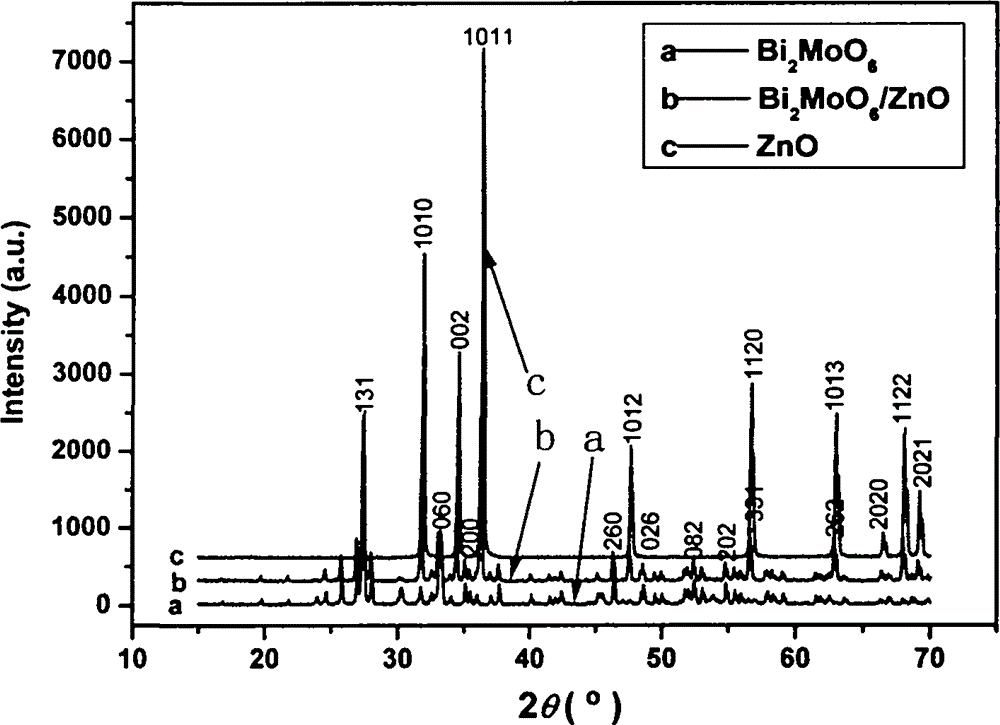

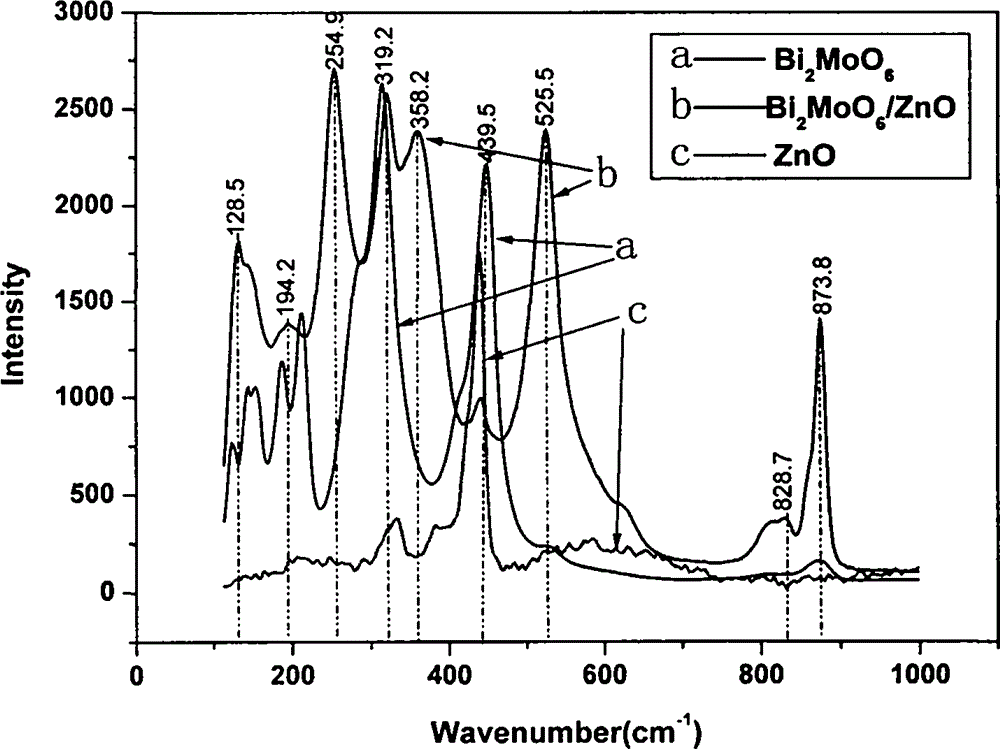

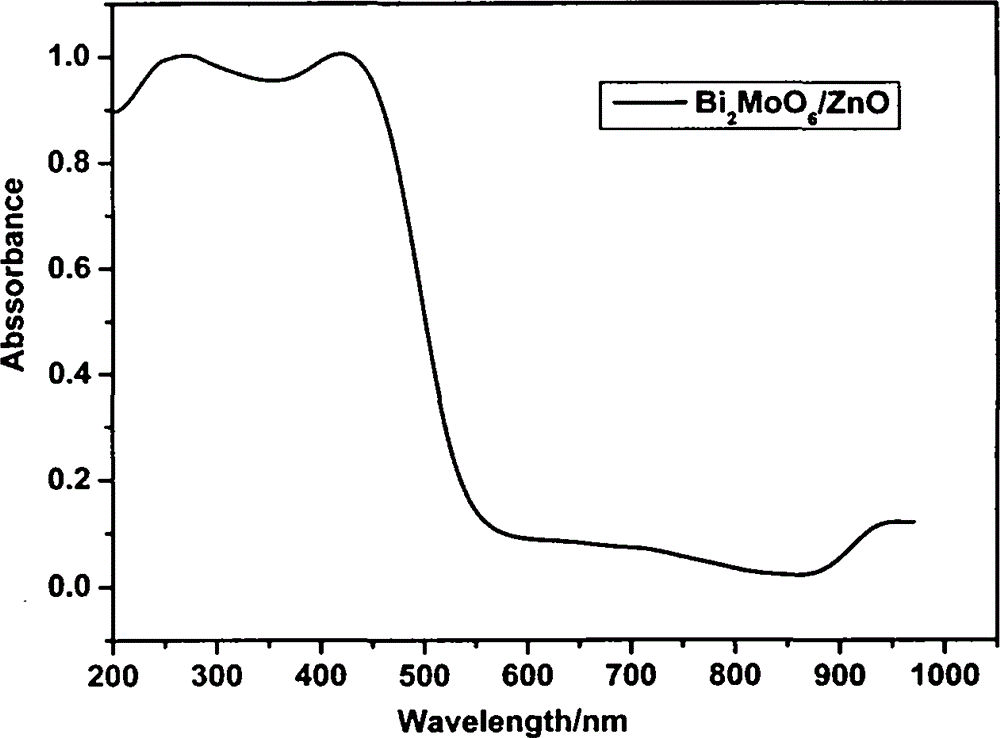

Bi2MoO6-ZnO composite photocatalyst and preparation method thereof

A technology of zinc oxide and composite light, which is applied in the field of composite materials and photocatalysis, can solve the problems of poor photocatalytic effect and weak response ability of bismuth molybdate, and achieve good photocatalytic degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First add 1 drop of 6mol / L nitric acid to 15ml of deionized water, disperse 5mmol of bismuth nitrate evenly into the above acid solution, then slowly add 10ml of 0.25mol / L sodium molybdate solution into the above aqueous solution , and stir evenly to obtain solution A; add 0.125 mmol of zinc acetate to 10 ml of isopropanol, and stir well to obtain solution B. Then slowly pour solution B into solution A, stir at room temperature for 30 minutes, add 5 mol / L ammonia solution, and adjust the pH value of the solution to neutral. Finally, transfer the above mixed solution to a 100 ml hydrothermal reaction kettle, and react at 140°C for 12 hours; after the hydrothermal reaction product is separated by high-speed centrifugation, it is washed with distilled water and absolute ethanol, repeated centrifugal washing several times, and then placed in a vacuum oven Dry in medium to obtain bismuth molybdate-zinc oxide composite photocatalyst.

Embodiment 2

[0021] First add 2 drops of 6mol / L nitric acid to 15ml of deionized water, disperse 5mmol of bismuth nitrate evenly into the above acid solution, then slowly add 10ml of 0.25mol / L sodium molybdate solution into the above aqueous solution , and stir evenly to obtain solution A; add 0.125 mmol of zinc acetate to 10 ml of isopropanol, and stir well to obtain solution B. Then slowly pour solution B into solution A, stir at room temperature for 30 minutes, add 5 mol / L ammonia solution, and adjust the pH value of the solution to neutral. Finally, transfer the above mixed solution to a 100 ml hydrothermal reaction kettle, and react at 160°C for 12 hours; after the hydrothermal reaction product is separated by high-speed centrifugation, it is washed with distilled water and absolute ethanol, repeated centrifugal washing several times, and then placed in a vacuum oven Dry in medium to obtain bismuth molybdate-zinc oxide composite photocatalyst.

Embodiment 3

[0023] First add 2 drops of 6mol / L nitric acid to 15ml of deionized water, disperse 5mmol of bismuth nitrate evenly into the above acid solution, then slowly add 10ml of 0.25mol / L sodium molybdate solution into the above aqueous solution , and stir evenly to obtain solution A; add 0.125 mmol of zinc acetate to 10 ml of isopropanol, and stir well to obtain solution B. Then slowly pour solution B into solution A, stir at room temperature for 30 minutes, add 5 mol / L ammonia solution, and adjust the pH value of the solution to neutral. Finally, transfer the above mixed solution to a 100ml hydrothermal reaction kettle, and react at 180°C for 12 hours; after the hydrothermal reaction product is separated by high-speed centrifugation, it is washed with distilled water and absolute ethanol, repeated centrifugal washing several times, and then placed in a vacuum oven Dry in medium to obtain bismuth molybdate-zinc oxide composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com