Method for preparing pile face doped zinc oxide transparent conductive film

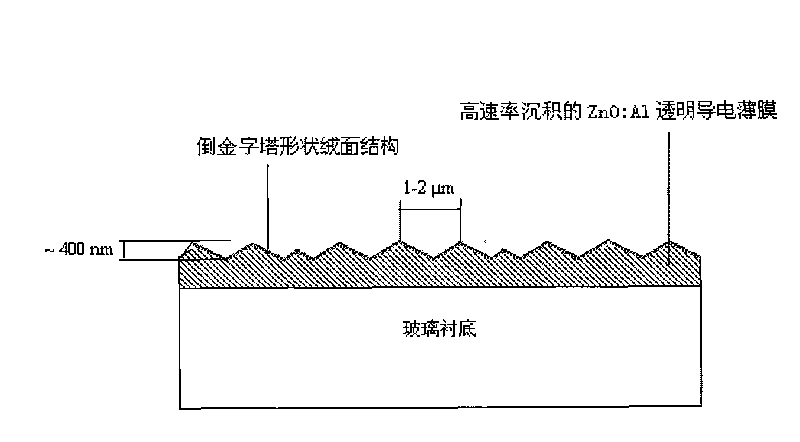

A transparent conductive film, aluminum-doped zinc oxide technology, used in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problem that surface structure cannot be obtained, light trapping effect cannot be achieved, and it is difficult to etch into inverted Pyramid-shaped suede and other problems, to achieve the effect of improving photoelectric conversion efficiency, improving efficiency, and increasing short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

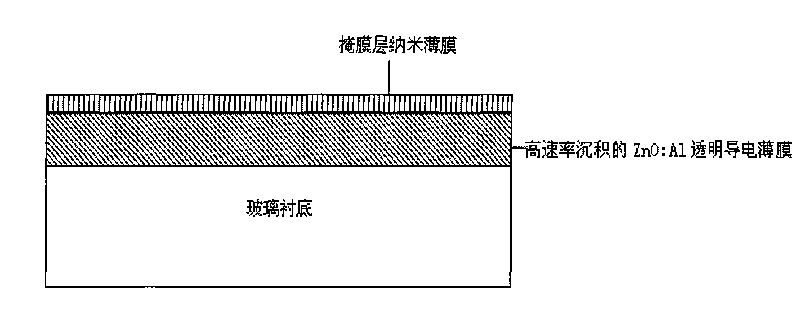

[0053] Deposition of ZnO:Al film as a mask layer by sputtering at low rate

[0054] First prepare the ZnO:Al transparent conductive film deposited at a high rate: the specific steps include:

[0055] (1) Clean the glass substrate (30cm×30cm or 10cm×10cm). The glass substrate is ultrasonically cleaned with acetone and alcohol for 60 minutes, cleaned with deionized water, and then dried with pure nitrogen or ultrasonically cleaned with acetone and alcohol. The cleaned glass substrate is placed in a spin dryer to dry;

[0056] (2), put the cleaned glass substrate into the sample loading chamber of the sputtering system to vacuumize, and heat the substrate. For a target material with a doping concentration of 2wt%, the heated substrate temperature needs to be Above 250°C, and for the doping concentration of 1wt%, the heated substrate temperature needs to be above 300°C, and for the doping concentration of 0.5wt%, the heated substrate temperature needs to be above 350°C, and for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com