Method for preparing aluminum-doped zinc oxide coated lithium manganese material

An aluminum-doped zinc oxide, lithium-rich manganese technology, applied in the field of nanomaterials, can solve the problems of poor cycle performance and low Coulomb efficiency, and achieve the effects of low equipment requirements, easy synthesis process, and improved transmission performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

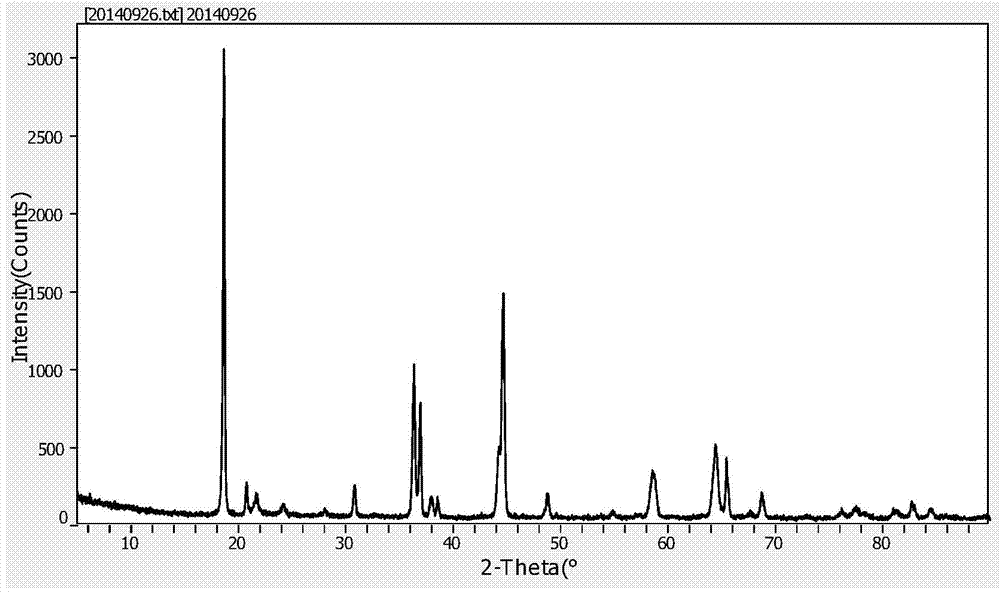

Image

Examples

Embodiment 1

[0032] A preparation method of aluminum-doped zinc oxide coating lithium-rich manganese material, comprising the following steps:

[0033] Step 1) Lithium-rich manganese 0.5Li 2 MnO 3 ·0.5LiNi 1 / 3 Mn 1 / 3 Co 1 / 3 O 2 Preparation of cathode materials

[0034] According to the molecular formula 0.5Li 2 MnO 3 ·0.5LiNi 1 / 3 Mn 1 / 3 Co 1 / 3 O 2 Weigh 10.86g (0.1575mol) of lithium nitrate, 4.83g (0.0166mol) of nickel nitrate, 4.83g (0.0166mol) of cobalt nitrate, 16.37g (0.0668mol) of manganese acetate, and prepare a 500ml of ionic aqueous solution, placed in a constant temperature water bath with a preheating temperature of 70°C, under vigorous stirring, citric acid solution (preparation: 33.1g (0.1575mol) citric acid dissolved in 500ml deionized water) was added dropwise to the metal in salt solution. Subsequently, the pH value was adjusted to about 7.5 with ammonia water, and the solvent was slowly distilled off under the condition of stirring at 90° C. to obtain a green t...

Embodiment 2

[0039] A preparation method of aluminum-doped zinc oxide-coated lithium-rich manganese material, comprising the following steps: the reaction environment and conditions of Example 2 are the same as those of Example 1, the difference is that in step 1), 0.5Li is prepared 2 MnO 3 ·0.5LiMn 1 / 2 Ni 1 / 2 O 2 Lithium-rich manganese cathode material.

[0040] Step 2) 4wt% Al-doped ZnO-coated Li-rich Manganese 0.5Li 2 MnO 3 ·0.5LiMn 1 / 2 Ni 1 / 2 O 2 Preparation of cathode materials

[0041] According to Al(NO 3 ) 3 ·9H 2 O and Zn(CH 3 COO) 2 ·2H 2 O molar ratio of 1:20 and weighed 0.0451g (0.1203mmol) Al(NO 3 ) 3 ·9H 2 O and 0.5281 g (2.4057 mmol) Zn(CH 3 COO) 2 ·2H 2 O was sequentially dissolved in 200 ml of deionized water. 100ml of 15% polyvinylpyrrolidone K30 or tartaric acid aqueous solution was added dropwise, stirred for 1h, doped with ZnO and 0.5Li according to Al 2 MnO 3 ·0.5LiMn 1 / 2 Ni 1 / 2 O 2 The mass ratio is 1:25 to weigh 5g0.5Li 2 MnO 3 ·0.5LiMn ...

Embodiment 3

[0043] A preparation method of aluminum-doped zinc oxide-coated lithium-rich manganese material, comprising the following steps: the reaction environment and conditions of Example 3 are the same as those of Example 1, the difference is that in step 1), 0.4Li is prepared 2 MnO 3 ·0.6LiNi 1 / 2 Mn 1 / 2 O 2 Lithium-rich manganese cathode material.

[0044] Step 2) 3wt% Al-doped ZnO-coated Li-rich Manganese 0.4Li 2 MnO 3 ·0.6LiNi 1 / 2 Mn 1 / 2 O 2 Preparation of cathode materials

[0045] According to Al(NO 3 ) 3 ·9H 2 O and Zn(CH 3 COO) 2 ·2H 2 O mole ratio 1:25, weigh 0.0272g (0.0725mmol) Al(NO 3 ) 3 ·9H 2 O and 0.398 g (1.8133 mmol) Zn(CH 3 COO) 2 ·2H 2 O was sequentially dissolved in 200 ml of deionized water. 100ml of 15% polyvinylpyrrolidone K30 or tartaric acid aqueous solution was added dropwise, stirred for 1h, doped with ZnO and 0.4Li according to Al 2 MnO 3 ·0.6LiNi 1 / 2 Mn 1 / 2 O 2 The mass ratio is 3:100 to weigh 5g of 0.4Li 2 MnO 3 ·0.6LiNi 1 / 2 M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com