Method for preparing copper-indium-gallium-selenide (CIGS) solar photovoltaic cell

A photovoltaic cell and solar energy technology, applied in circuits, electrical components, final product manufacturing, etc., can solve the problems of low photoelectric conversion efficiency of batteries, large consumption of raw materials, poor repeatability, etc., and achieve high photoelectric conversion efficiency and uniform composition. , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

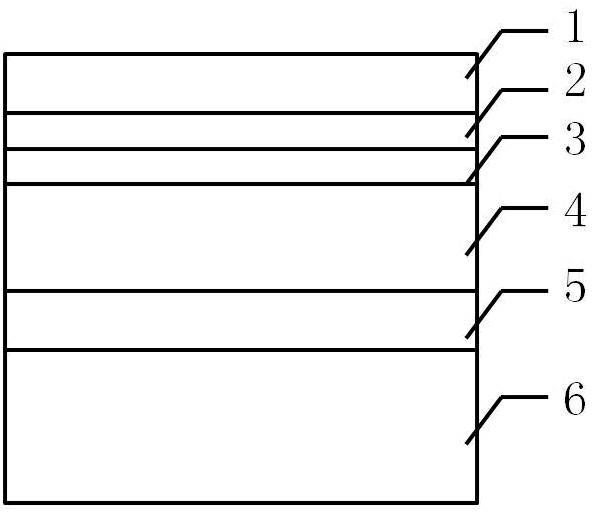

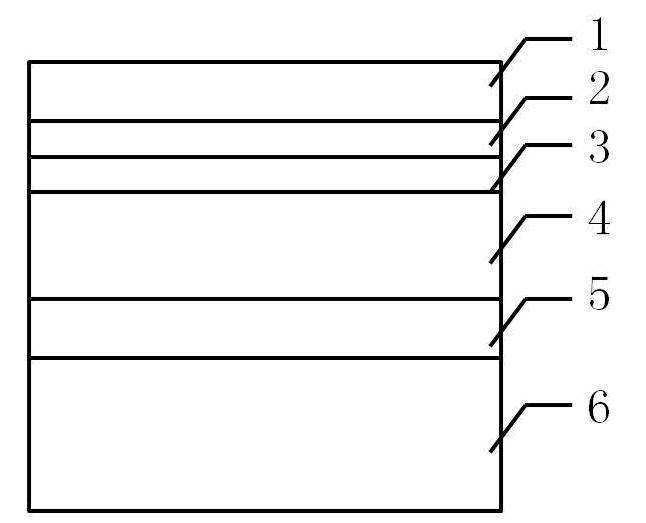

[0023] Embodiment 1: prepare CIGS solar photovoltaic cell according to the following steps:

[0024] (1) Clean the glass substrate: soak the glass substrate in 5% potassium hydroxide (KOH) aqueous solution for 60 o C for 15 minutes, then rinse with water and dry with air;

[0025] (2) Sputtering molybdenum (Mo) metal: In the magnetron sputtering equipment, with argon (Ar) as the gas source and molybdenum metal as the target source, under the vacuum degree of 0.5 Pa, the glass in step 1 A layer of 0.5 micron thick molybdenum metal film is sputtered on the substrate as the back electrode;

[0026] (3) Copper (Cu) indium (In) gallium (Ga) alloy sputtering: In the magnetron sputtering equipment, argon gas is used as the gas source, copper gallium alloy (Cu / Ga=4) and indium are used as the target source, Under the vacuum of 0.5Pa, the copper indium gallium alloy with a thickness of 1.0 micron is continuously sputtered on the molybdenum metal coating in step 2 as the absorber laye...

Embodiment 2

[0031] Embodiment 2: prepare CIGS solar photovoltaic cell according to the following steps:

[0032] (1) Clean the glass substrate: soak the glass substrate in 5% potassium hydroxide (KOH) aqueous solution for 60 o Soak under C for 15 minutes, then rinse with water and blow dry with nitrogen;

[0033] (2) Sputtering molybdenum (Mo) metal: In the magnetron sputtering equipment, argon (Ar) is used as the gas source and molybdenum metal is used as the target source. A layer of 1 micron thick molybdenum metal film is sputtered on the top as the back electrode;

[0034] (3) Copper (Cu) indium (In) gallium (Ga) alloy sputtering: In the magnetron sputtering equipment, argon gas is used as the gas source, copper gallium alloy (Cu / Ga=4) and indium are used as the target source, Under the vacuum degree of 1Pa, continue sputtering a layer of copper indium gallium alloy with a thickness of 1.5 microns on the molybdenum metal coating in step 2 as the precursor of the absorber layer. The ...

Embodiment 3

[0039] Embodiment 3: prepare CIGS solar photovoltaic cell according to the following steps:

[0040] (1) Clean the glass substrate: soak the glass substrate in 5% potassium hydroxide (KOH) aqueous solution for 60 o C for 15 minutes, then rinse with water and dry with air;

[0041] (2) Sputtering molybdenum (Mo) metal: In the magnetron sputtering equipment, argon (Ar) is used as the gas source, molybdenum metal is used as the target source, and the glass substrate in step 1 is A layer of 1.5 micron thick molybdenum metal film is sputtered on the top as the back electrode;

[0042] (3) Copper (Cu) indium (In) gallium (Ga) alloy sputtering: In the magnetron sputtering equipment, argon gas is used as the gas source, copper gallium alloy (Cu / Ga=4) and indium as the target source, Under a vacuum degree of 2 Pa, continue sputtering a layer of copper indium gallium alloy with a thickness of 2.0 microns on the molybdenum metal coating in step 2 as the precursor of the absorber layer....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com