Composite back reflection metal electrode for thin film solar cell, as well as preparation method and application of composite back reflective metal electrode

A technology of thin-film solar cells and metal electrodes, which is applied in the manufacture of circuits, electrical components, and final products. The effect of peeling off and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

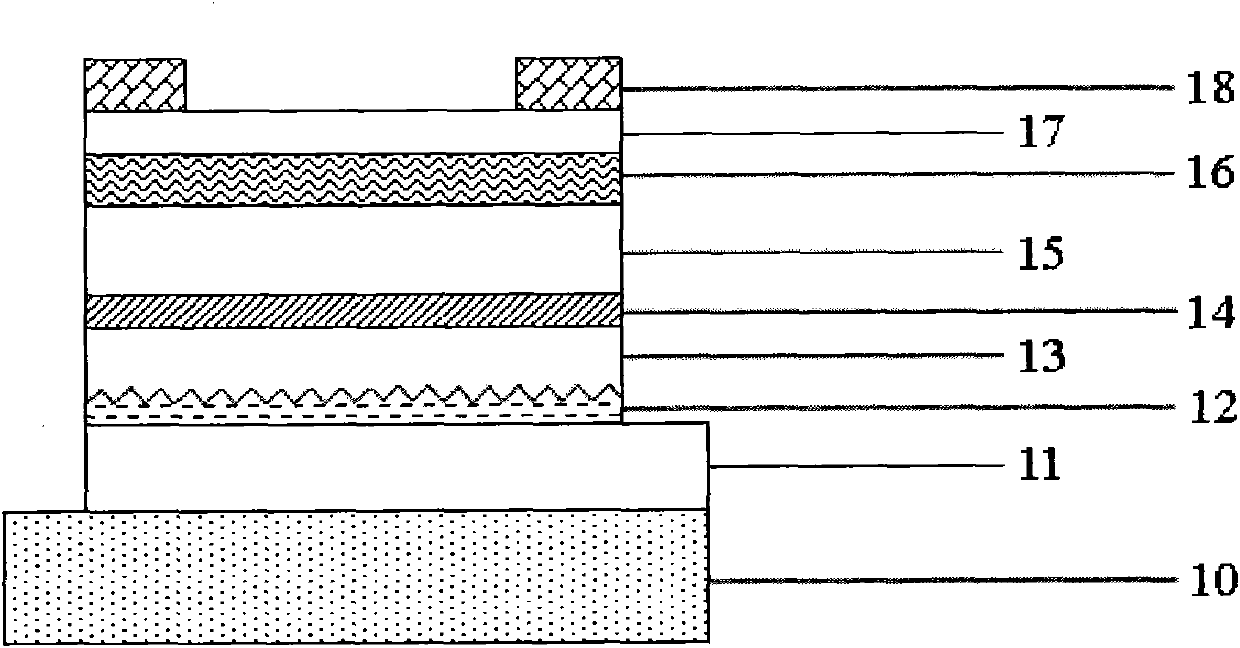

[0030] figure 1 A schematic diagram of the structure of a single-junction silicon-based thin-film solar cell comprising a composite back-reflecting metal electrode of the present invention is provided. According to the present invention, the main steps of preparing the main body of the solar cell are as follows:

[0031] The first step: put the prepared substrate containing the metal transition layer (nickel or cadmium or copper or titanium), the textured silver film, and the aluminum-doped zinc oxide barrier layer into the plasma-enhanced chemical vapor deposition system, the substrate Bake at 200°C for 1 hour;

[0032] The second step: sequentially deposit n, i, p three layers of silicon-based films in different chambers;

[0033] Step 3: Cool down to room temperature, take out the sample; place the sample prepared with silicon-based thin film in the coating system, and prepare aluminum-doped zinc oxide, tin dioxide or indium tin oxide transparent conductive film;

[0034]...

Embodiment 2

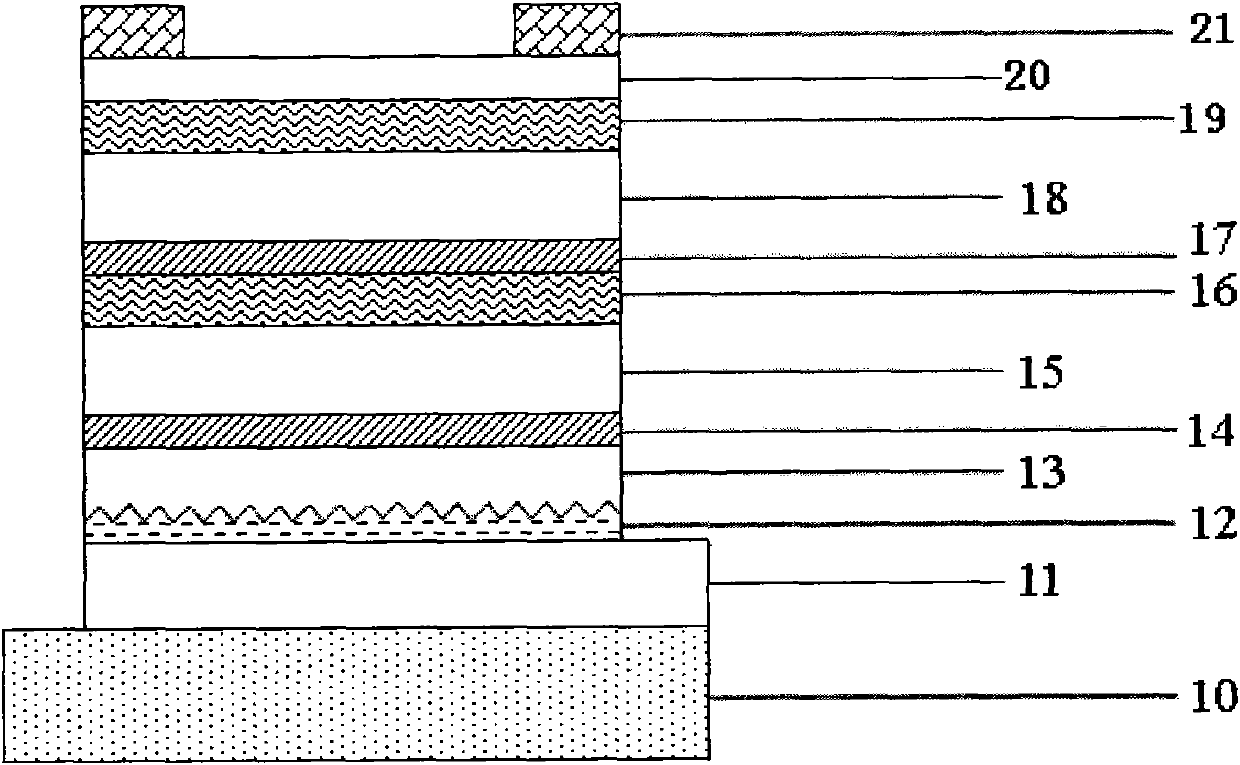

[0038] image 3A schematic structural view of a multi-junction silicon-based thin-film solar cell comprising a composite back-reflecting metal electrode of the present invention is provided. According to the present invention, the main steps of preparing the solar cell body are as follows:

[0039] The first step: put the prepared substrate containing the metal transition layer (nickel or cadmium or copper or titanium), the textured silver film, and the aluminum-doped zinc oxide barrier layer into the plasma-enhanced chemical vapor deposition system, the substrate Bake at 200°C for 1 hour;

[0040] The second step: sequentially deposit n, i, p three layers of silicon-based films 14-16 in different chambers;

[0041] Step 3: sequentially deposit n, i, p three layers of silicon-based films 17-19 in different chambers;

[0042] Step 4: Cool down to room temperature, take out the sample; place the sample prepared with silicon-based thin film in the coating system, and prepare al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com