Anti-static modified polyester staple fiber and preparation method thereof

A polyester staple fiber, antistatic technology, applied in the field of polymer material processing, can solve the problem of high static electricity, etc., achieve the effect of enhanced antistatic ability, stable production process, and enhanced dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

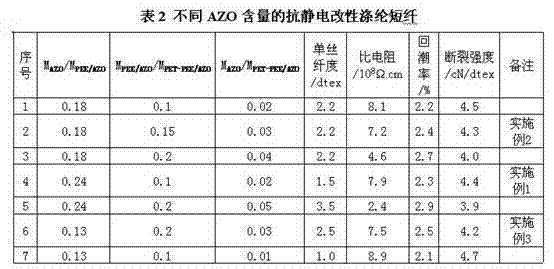

Examples

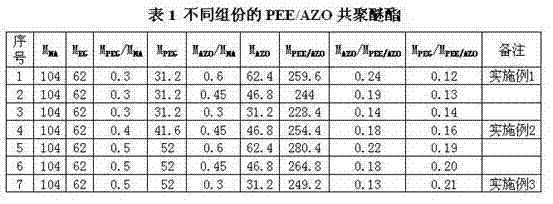

Embodiment 1

[0037] (1) Preparation of PEE / AZO composite polyether ester

[0038] A 5,000-ton / year continuous polymerization device is used, including beating kettle, esterification kettle 1, esterification kettle 2, esterification kettle 3, polycondensation kettle, and pelletizer.

[0039] In the second esterification kettle, the esterification reaction of PEE / AZO composite polyether ester is carried out.

[0040] Raw materials: MA,

[0041] EG, with a molar ratio of 1.08:1 relative to MA,

[0042] Polyether PEG (molecular weight 600), accounting for 30% of the mass of MA,

[0043] Aluminum doped with zinc oxide (AZO), accounting for 60% of the mass of MA.

[0044] The preparation process is as follows: use KH550 to modify the surface of AZO with an average particle size of about 100nm, add 1.5% of the mass of AZO, and control the pH value of the solution to 8.5. Add the modified AZO into the EG solution for dispersion, control the solution concentration to 50% (wt), and use ultrasoni...

Embodiment 2

[0050] (1) Preparation of PEE / AZO composite polyether ester

[0051] Same as the equipment and technological process adopted in embodiment 1.

[0052] In the second esterification kettle, the esterification reaction of PEE / AZO composite polyether ester is carried out. The preparation process is as follows:

[0053] MA,

[0054] EG, with a molar ratio of 1.15:1 relative to MA,

[0055] Polyether PEG (molecular weight 1000), accounting for 40% of the mass of MA,

[0056] Aluminum-doped zinc oxide (AZO), accounting for 45% of the mass of MA,

[0057] Use KH550 to modify the surface of AZO with an average particle size of about 100nm. The amount added is 1.5% of the mass of AZO, and the pH of the solution is controlled to be 8.5. Add the modified AZO into the EG solution for dispersion, control the solution concentration to 43% (wt), and use ultrasonic treatment for 24hr. Add the dispersed AZO / EG solution together with MA and PEG into the second esterification kettle for est...

Embodiment 3

[0063] (1) Preparation of PEE / AZO composite polyether ester

[0064] Same as the equipment and technological process adopted in embodiment 1.

[0065] In the second esterification kettle, the esterification reaction of PEE / AZO composite polyether ester is carried out. The preparation process is as follows:

[0066] MA,

[0067] EG, with a molar ratio of 1.2:1 relative to MA,

[0068] Polyether PEG (molecular weight 2000), accounting for 50% of the mass of MA,

[0069] Aluminum-doped zinc oxide (AZO), 30% by mass of MA,

[0070] Use KH550 to modify the surface of AZO with an average particle size of about 100nm. The amount added is 1.5% of the mass of AZO, and the pH of the solution is controlled to be 8.5. Add the modified AZO into the EG solution for dispersion, control the solution concentration to 33% (wt), and use ultrasonic treatment for 24hr. Add the dispersed AZO / EG solution together with MA and PEG into the second esterification kettle for esterification reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com