A catalyst-loaded graphene-modified polyester chip and preparation method thereof

A technology of graphene modification and catalyst loading, which is applied in the field of polyester synthesis, which can solve the problems of affecting wearing comfort, inability to improve polyester fiber wearing comfort, and high hardness. The effect of less, excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

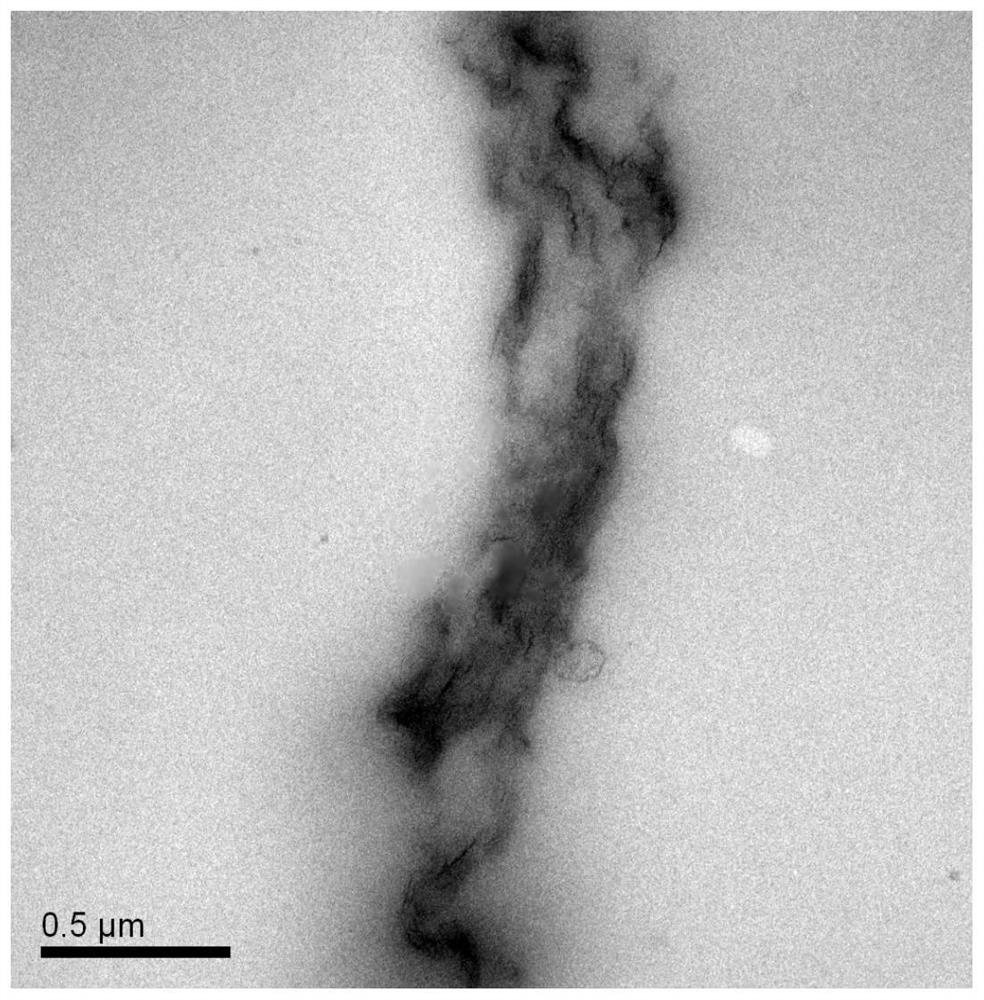

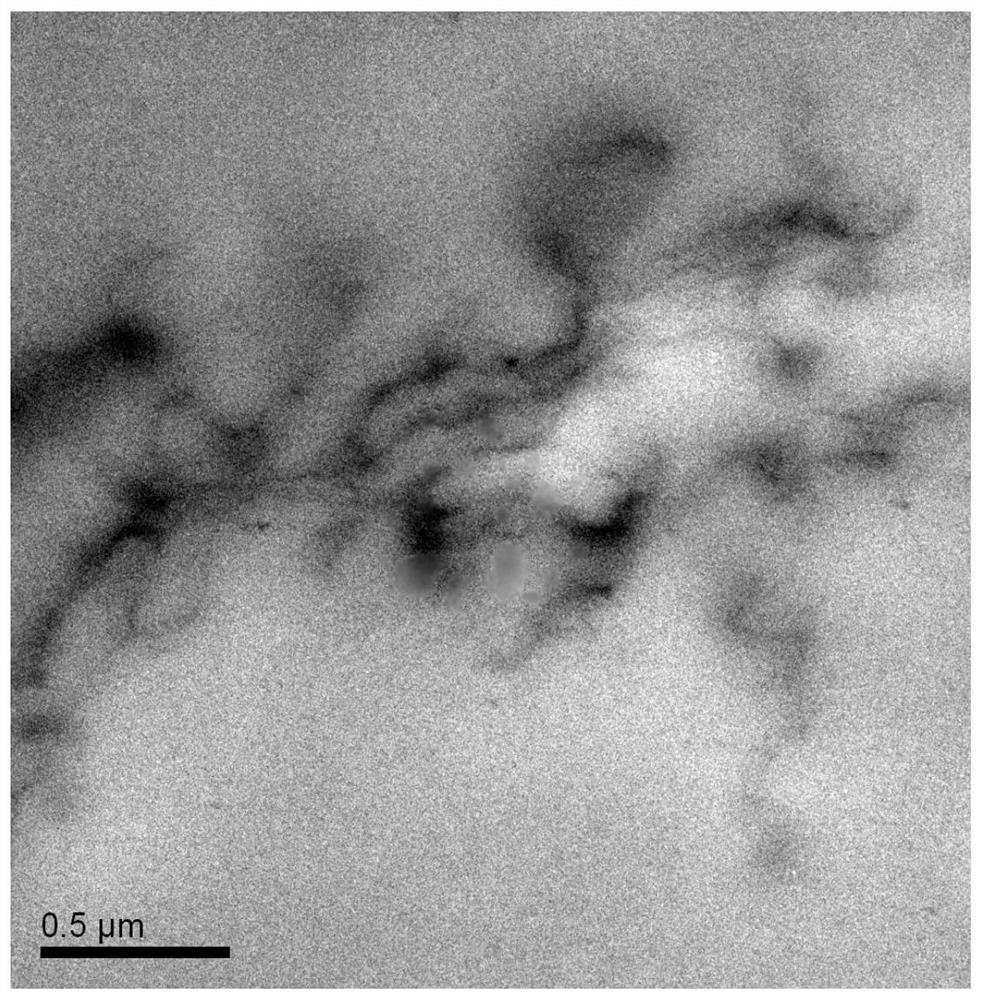

Image

Examples

Embodiment 1

[0030] 1) Add 1 part of antimony trioxide and 10 parts of ethylene glycol into a three-necked flask, heat and stir in an electric heating mantle, control the reaction temperature at 190°C, condense and reflux for 4 hours, and remove the generated water in time with a water separator , After reacting for 2.5h, change to vacuum distillation at a temperature of 135°C to remove traces of water and unreacted ethylene glycol remaining in the reaction process. Until the reaction solution is clear and transparent, perform hot filtration.

[0031] 2) Add 0.3 parts of graphene powder to the above-mentioned filtrate after vacuum drying, let it stand at room temperature, filter immediately when crystals are precipitated, take the filter cake, dry it in vacuum, weigh it, and obtain a black powder.

[0032] 3) Add 2 parts of ethylene glycol to the above black powder and ultrasonically disperse for 0.5 hours to prepare an additive mixture.

[0033] 4) Slurry 90 parts of terephthalic acid an...

Embodiment 2

[0035] 1) Add 1 part of antimony trioxide and 9 parts of ethylene glycol into a three-necked flask, heat and stir in an electric heating mantle, control the reaction temperature at 195°C, condense and reflux for 4.5 hours, and remove the formed product in time with a water separator Water, after reacting for 2.5 hours, change to vacuum distillation at 140°C to remove traces of water and unreacted ethylene glycol remaining during the reaction. Until the reaction solution is clear and transparent, perform hot filtration.

[0036] 2) Add 0.2 parts of graphene oxide powder to the above-mentioned filtrate after vacuum drying, let it stand at room temperature, filter immediately when crystals are precipitated, take the filter cake, dry it in vacuum, weigh it, and obtain a black powder.

[0037] 3) Add 2.5 parts of ethylene glycol to the above black powder and ultrasonically disperse for 1 hour to prepare an additive mixture.

[0038] 4) Slurry 90 parts of terephthalic acid and 40 p...

Embodiment 3

[0040] 1) Add 1 part of antimony trioxide and 11 parts of ethylene glycol into a three-necked flask, heat and stir in an electric heating mantle, control the reaction temperature at 186°C, condense and reflux for 4 hours, and remove the generated water in time with a water separator After 2.5 hours of reaction, the reaction was changed to vacuum distillation at a temperature of 150° C. to remove traces of water and unreacted ethylene glycol remaining during the reaction. Until the reaction solution is clear and transparent, perform hot filtration.

[0041] 2) Add 0.5 parts of graphene oxide powder to the above-mentioned filtrate after vacuum drying, let it stand at room temperature, filter immediately when crystals are precipitated, take the filter cake, dry it in vacuum, weigh it, and obtain a black powder.

[0042] 3) Add 2 parts of ethylene glycol to the above black powder and ultrasonically disperse for 0.5 hours to prepare an additive mixture.

[0043] 4) Slurry 90 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com