Method for annealing aluminum-doped zinc oxide transparent conductive thin film

A transparent conductive film, zinc oxide technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of reducing the surface roughness of the film, increasing the surface roughness of the film, and deteriorating the conductive properties of the film , to achieve the effect of reducing film resistivity and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: Co-sputtering low temperature, high speed deposition annealing AZO transparent conductive film

[0014] The quartz substrate was ultrasonically cleaned with acetone and alcohol, and then placed in a magnetron sputtering coating machine for reverse sputtering cleaning. The purity of the zinc oxide ceramic target for sputtering is 99.9%, the purity of the aluminum oxide target is 99.9%, and the relative density is greater than 90%. Install the targets in two opposing target guns, and evacuate until the background vacuum of the vacuum chamber is higher than 2.0×10 -4 Pa. The substrate temperature is kept at 200°C, and 20 sccm of argon gas is introduced into the vacuum chamber (sccm means standard milliliter per minute), and the pressure of the vacuum chamber is adjusted to 0.15Pa. The power of the RF power supply corresponding to the zinc oxide target is adjusted to 100W, and the corresponding The power of the RF power supply was adjusted to 75W, the sample...

Embodiment 2

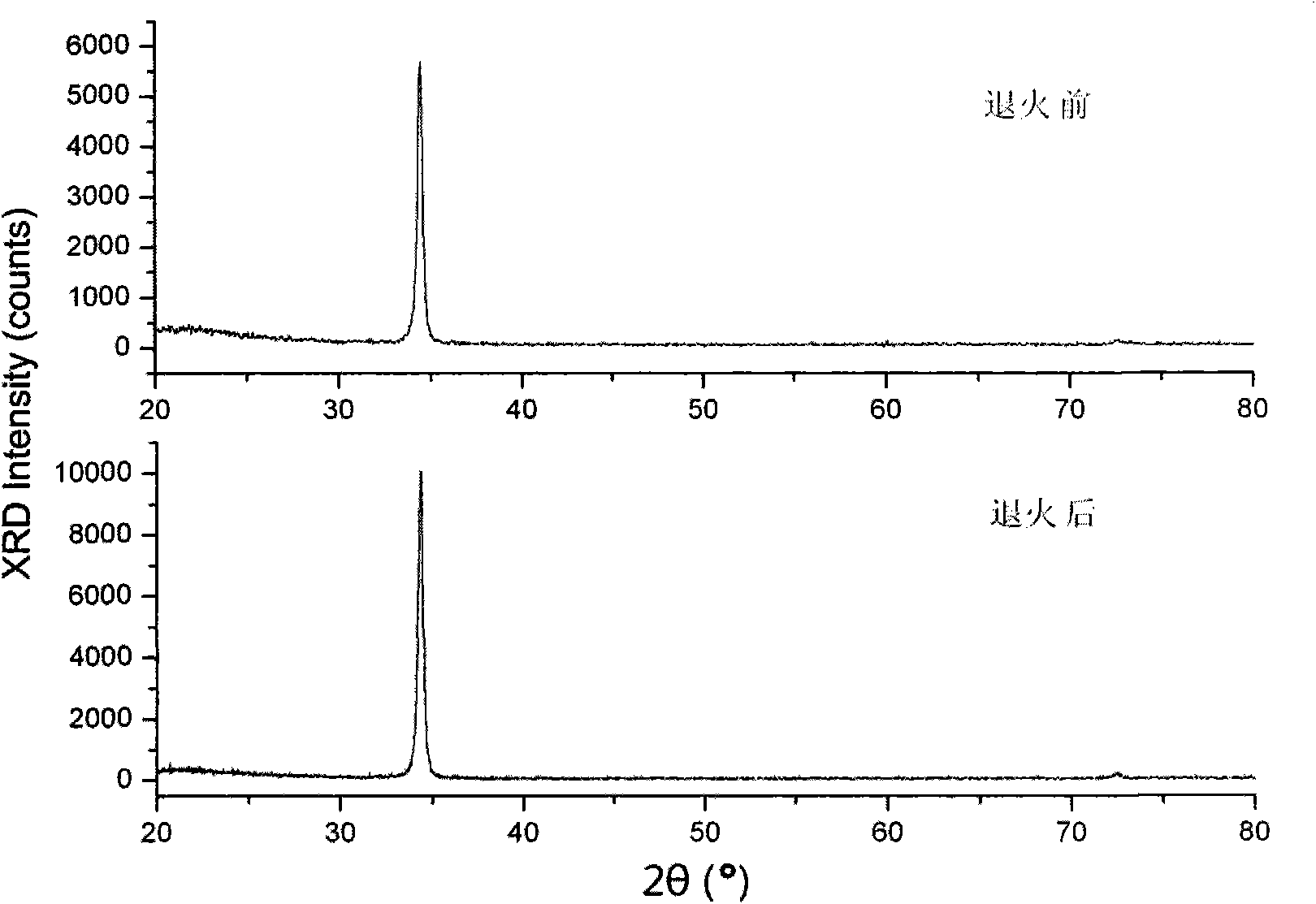

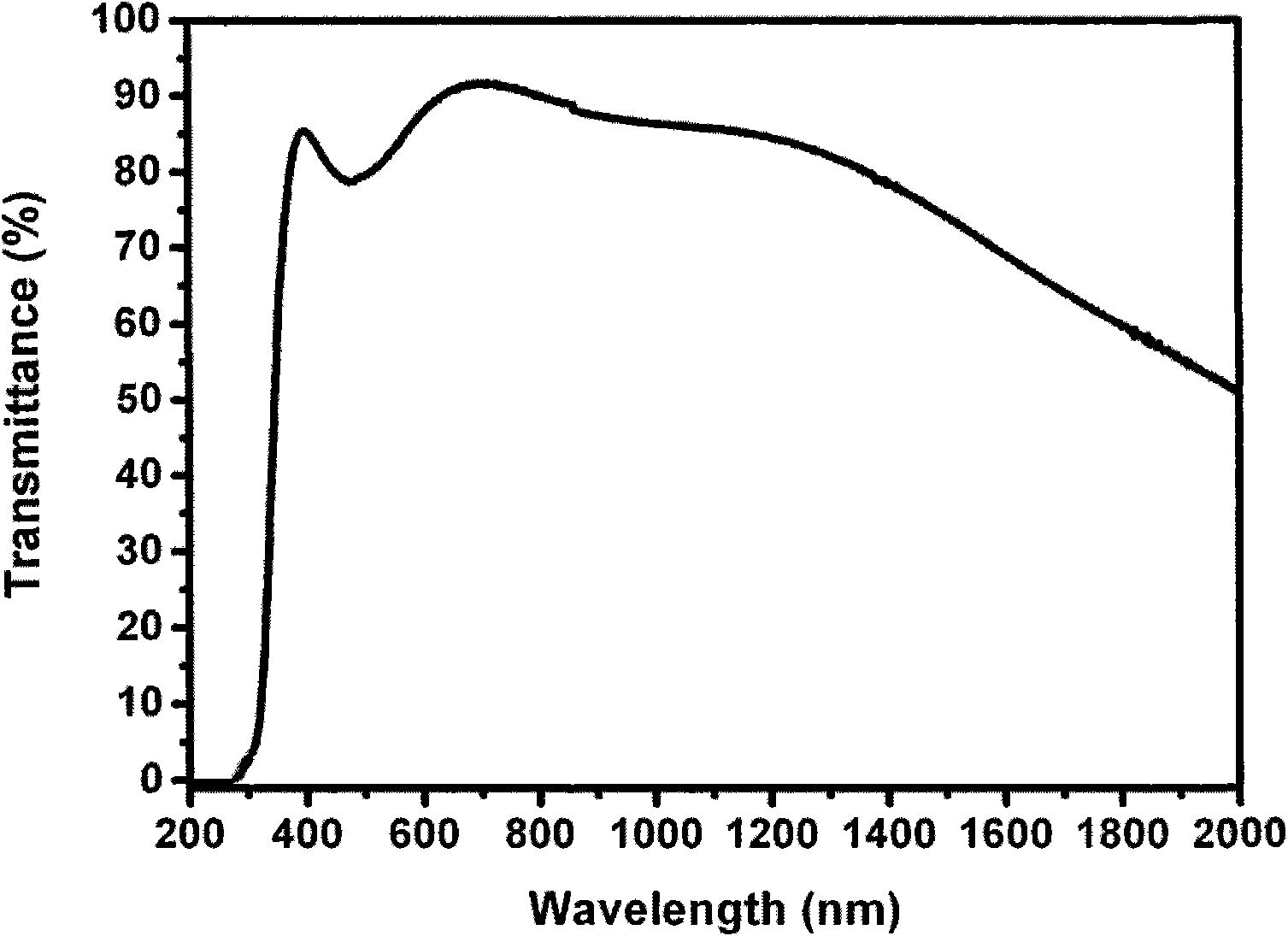

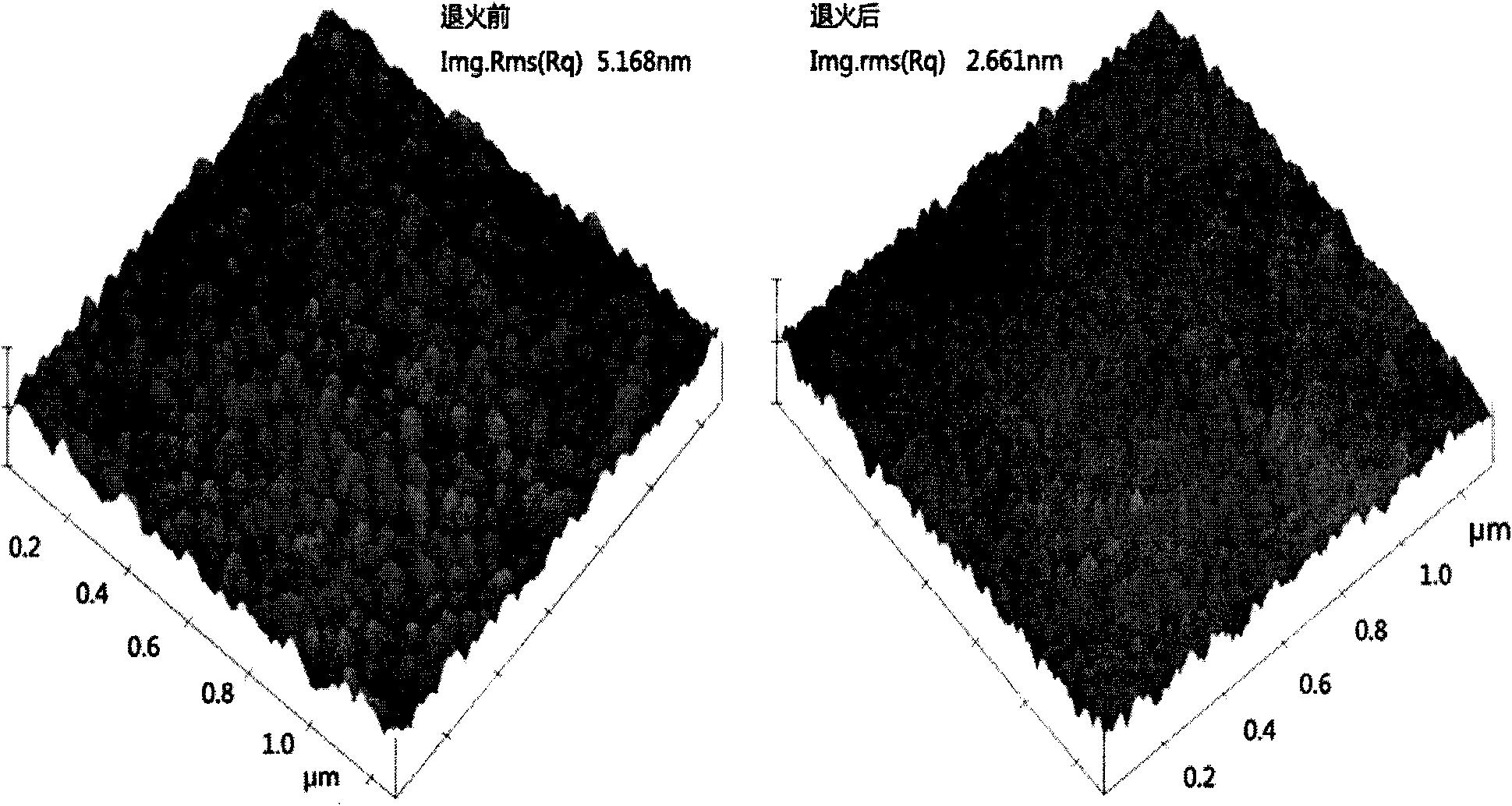

[0016] Put the sample deposited in Example 1 into the annealing furnace, turn on the mechanical pump to evacuate to 0.5 Pa, turn off the mechanical pump after 30 minutes, and feed 200 sccm of nitrogen gas to a slight positive pressure, raise the temperature to 300 ° C, turn off the nitrogen gas and feed in hydrogen gas, After annealing for 10 min, turn off the hydrogen gas and switch to nitrogen gas to lower the temperature. Tests show that the mass ratio of aluminum content to the sum of aluminum content and zinc content in the AZO transparent conductive film [W Al / (W Al +W Zn )]≈2%, its crystal structure is a hexagonal wurtzite phase structure along the (002) orientation, and its resistivity is 5.94×10 -4 Ω·cm, the sheet resistance is 29.71Ω / □, and the carrier concentration is 1.88×10 21 / cm 3 , with a mobility of 5.61cm 2 V -1 S -1 , The average transmittance is greater than 80% in the wavelength range of 400-1000nm, and the surface roughness is 2.7nm.

Embodiment 3

[0018] Put the sample deposited in Example 1 into the annealing furnace, turn on the mechanical pump to evacuate to 0.5Pa, pass in 300sccm argon to a slight positive pressure, raise the temperature to 200°C and keep it for 30min, then change the flow to 100sccmH 2 and 200sccmN 2 After annealing for 20 minutes, turn off the hydrogen gas, and switch to argon gas to cool down. The test shows that the crystal structure of the AZO transparent conductive film is a hexagonal wurtzite phase structure along the (002) orientation, and the resistivity is 4.30×10 -4 Ω cm, the sheet resistance is 21.52Ω / □, and the carrier concentration is 1.22×10 21 / cm 3 , with a mobility of 12.83cm 2 V -1 S -1 , The average transmittance is greater than 80% in the wavelength range of 400-1000nm, and the surface roughness is 2.1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com