Oil-repellent coated corrugated case and preparation method thereof

A corrugated box and cloth corrugated technology, which is applied in the field of oil-proof coated corrugated box and its preparation, can solve the problems of waste and high cost, and achieve the effect of low cost, remarkable effect and excellent oil-proof protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: oil-proof coated corrugated box and its preparation method

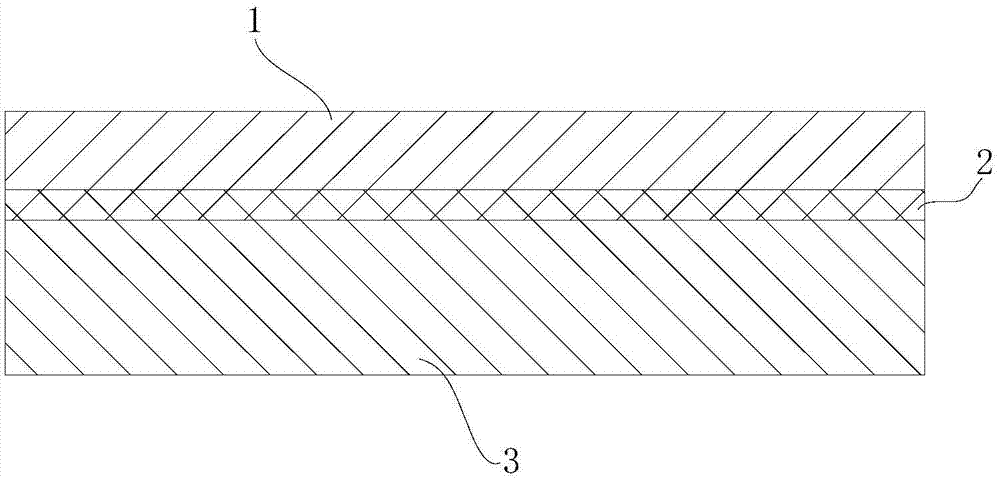

[0027] Participate in figure 1 As shown, the oil-repellent coated corrugated box is coated with a layer of oil-proof coating layer 1 on the inner surface of the corrugated box, and the oil-proof coating of the oil-proof coating layer 1 is partially pressed to the corrugated cardboard of the corrugated box by applying pressure Inside of original paper 3. Since the oil-repellent coating is pressed to the inside of the corrugated cardboard base paper 3 of the corrugated box by applying pressure, a bonding layer 2 is formed between the oil-repellent coating layer 1 and the corrugated cardboard base paper 3, so that the oil-repellent coating layer 1 and the corrugated cardboard The combination between base paper 3 is more tight.

[0028] The oil-proof coating is mainly composed of silicone-modified acrylic resin, water and surfactant, and the mass ratio is: 85:12:3; in other embodiments, a film-formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com