Method for utilizing photo-crosslinking polymers to conduct thin film packaging on organic electronic device

A technology of organic electronic devices and thin film packaging, applied in the fields of electric solid devices, electrical components, photovoltaic power generation, etc., can solve problems such as increased cost, time consumption limitation, and little research on packaging layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

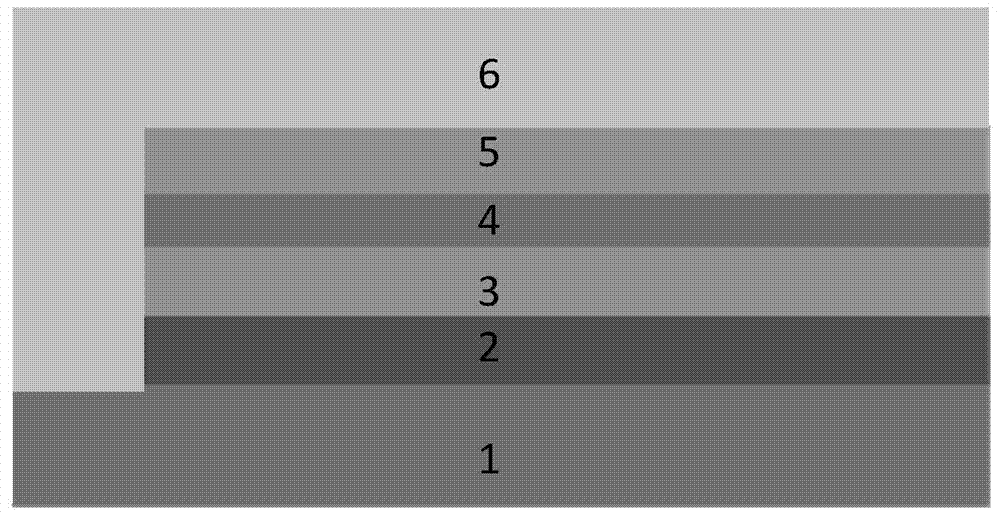

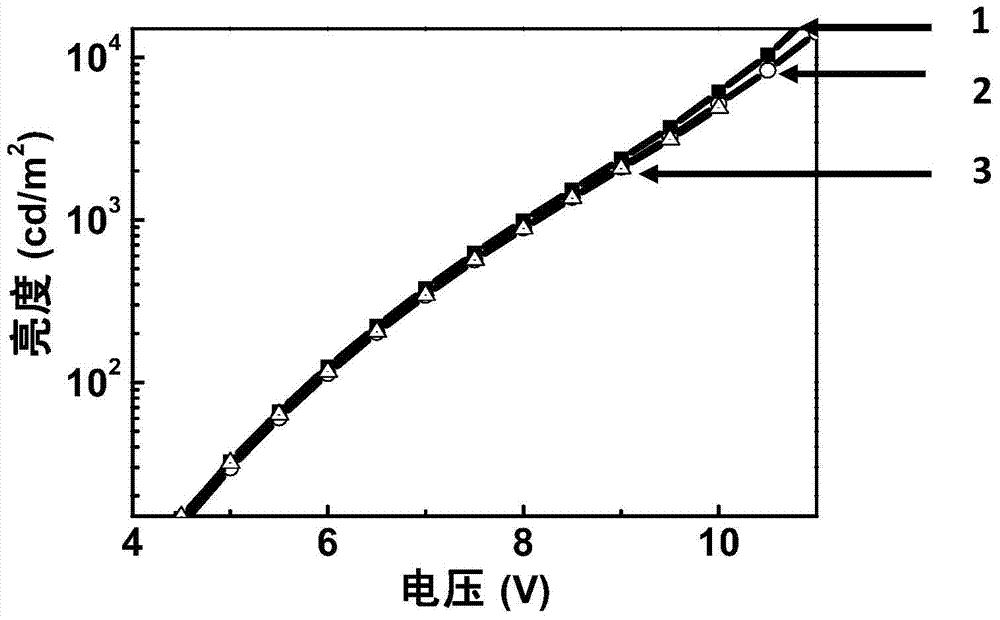

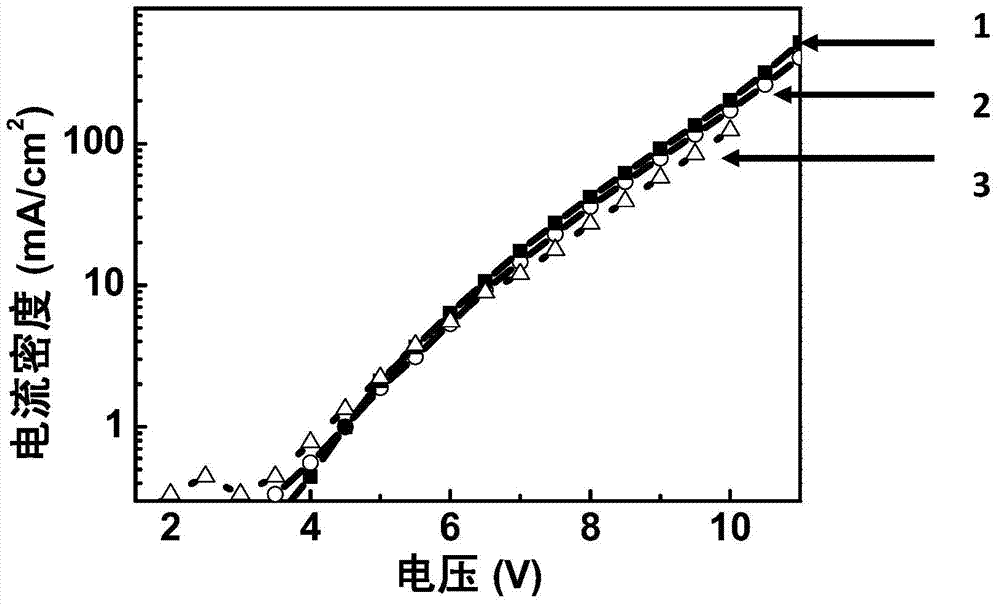

[0028] We prepared the structure as: glass / ITO / MoO 2 (5nm) / mMTDATA (30nm) / NPB(20nm) / Alq(50nm) / LiF(1nm) / Al OLED device. On this basis, A, B, and C three groups of devices were prepared. Among them, the devices in group A are not packaged, the devices in group B are packaged with glass cover (GCE), and the devices in group C are packaged in 16 μm NOA63.

[0029] The preparation process is as follows:

[0030] [1] The substrate material is ITO glass. First, the ITO glass is repeatedly scrubbed and cleaned with acetone and ethanol cotton balls;

[0031] [2] Put the scrubbed substrate into a clean beaker, then ultrasonically use acetone, ethanol, and deionized water for 10 minutes each, and then dry it in an oven to obtain a clean substrate free of chemical impurities and fine particles on the surface. end;

[0032] [3] Place the processed substrate in a multi-source organic molecular vapor deposition system, the vacuum of the system can reach 10 -5 Pa, the vacuum degree of th...

Embodiment 2

[0035] Example 2: Electrical testing of equivalent Ca thin films of organic electronic devices

[0036] In order to accurately evaluate the barrier performance of the packaging film we prepared to water vapor, we have prepared the equivalent Ca thin film electrical test device of the organic electronic device that is spin-coated with NOA63 packaging film described in Example 1, and its device structure and parameters are : Ca(200nm) / Al(100nm) / NOA63(16μm);

[0037] Ca thin film electrical test device structure such as Figure 4 As shown, a glass substrate 41, a simple Ca film 42, two discrete Al contact electrodes 43, and a photocrosslinked polymer packaging film layer 44 are composed;

[0038] Ca elemental film (length 10mm, width 10mm, thickness 200nm) was prepared in the middle of the glass substrate (length 25mm, width 25mm), and the two discrete Al contact electrodes were convex structures (the length of the large area was 24mm, the largest The width of the area is 4mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com