Dental crown and manufacturing method thereof

A manufacturing method and technology for dental crowns, applied in dentistry, filling teeth, filling teeth, etc., can solve the problems of cumbersome steps, cumbersome processes, easy to brittle cracks, etc., and achieve the effect of reducing cumbersomeness, fast transmission, and good elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

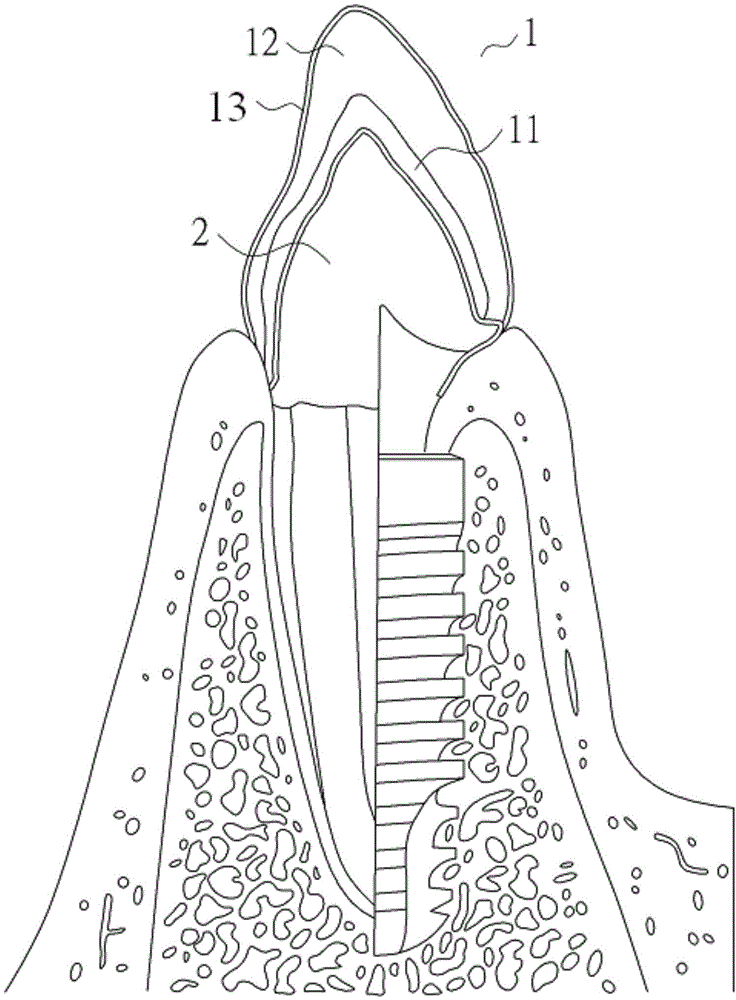

Embodiment 1

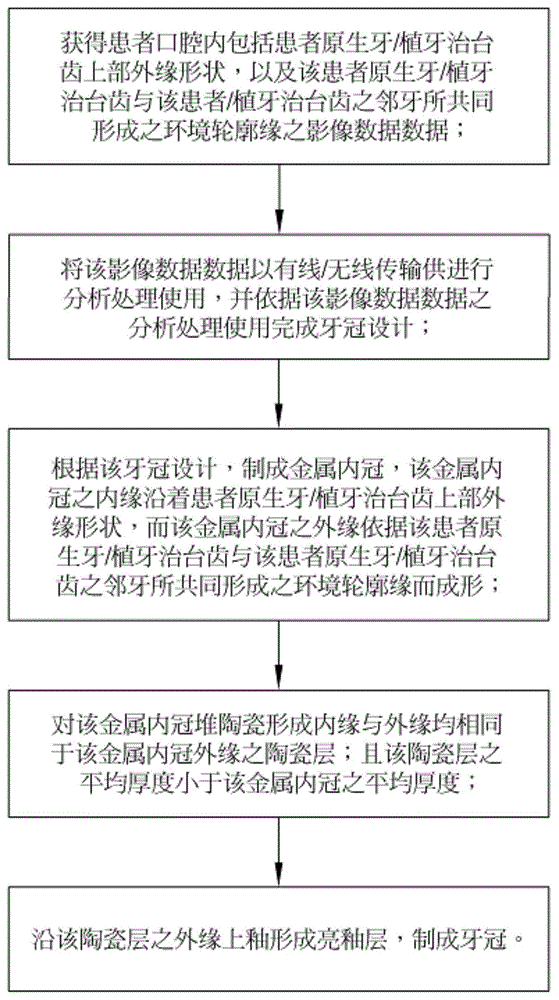

[0033] The invention provides a method for manufacturing a dental crown, comprising the following steps:

[0034] S1. Obtain the shape of the outer edge of the upper part of the patient's original teeth / implant teeth in the patient's oral cavity, and the environmental contour jointly formed by the patient's original teeth / implant teeth and the adjacent teeth of the patient / implant teeth edge image data;

[0035] S2. The image data is transmitted by wire / wireless for analysis and processing, and the crown design is completed according to the analysis and processing of the image data;

[0036] S3. According to the crown design, make a metal inner crown, the inner edge of the metal inner crown follows the shape of the outer edge of the upper part of the patient's original tooth / implant treatment table, and the outer edge of the metal inner crown is based on the shape The patient's original tooth / implant treatment set and the adjacent teeth of the patient's original tooth / implant...

Embodiment 2

[0048] see image 3 shown, and with figure 2 , the present invention relates to a method for manufacturing a dental crown, the steps comprising:

[0049] S1. Obtain the shape of the upper outer edge of the patient's original tooth / implantation tooth (Abutment) in the patient's oral cavity, as well as the patient's original tooth / implantation tooth (Abutment) and The image data of the environmental contour edge jointly formed by the adjacent teeth of the patient's original teeth / implantation teeth (Abutment);

[0050] S2. Transmit the image data to the database of the dental crown design unit via a wired / wireless network;

[0051] S3. The image data is transmitted by cable / wireless for analysis and processing, and the crown design is completed based on the analysis and processing of the image data, and based on the design, metal powder is used, preferably as a material that does not affect the human body. A cobalt-nickel alloy, cobalt is strong in wear resistance, moderate ...

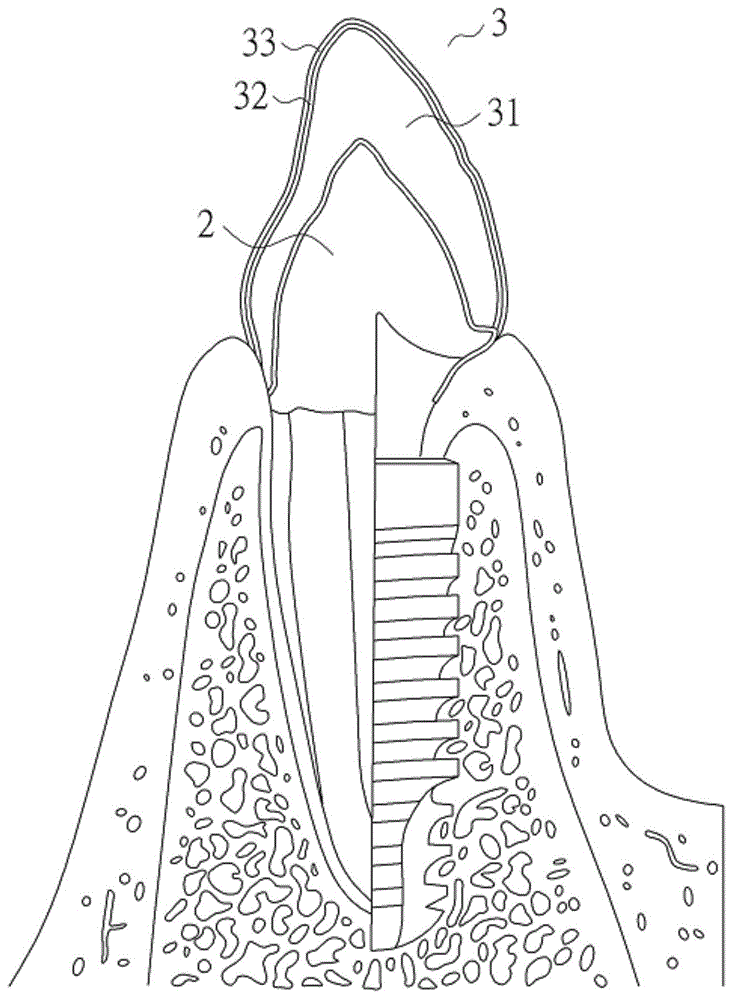

Embodiment 3

[0059] see figure 2 As shown, the present invention also provides a dental crown (3), which comprises: a metal inner crown (31) for covering the upper part of the patient's original tooth / implantation (2) Edge; ceramic layer (32), the average thickness of the ceramic layer (32) is less than the average thickness of the metal inner crown (31), and the inner and outer edges of the ceramic layer (32) are the same as the metal inner crown ( 31) Outer edge: The bright glaze layer (33) is laid along the outer edge of the ceramic layer (32).

[0060] As a more preferred solution of the present invention, in the present invention, the inner edge of the metal inner crown (31) is shaped along the upper outer edge of the patient's primary tooth / implantation tooth (Abutment) (2), and the metal inner crown ( The outer edge of 31) is based on the environmental contour edge formed by the patient's original tooth / implantation tooth (Abutment) (2) and the adjacent teeth of the patient's orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com