Dual-long-secondary and primary permanent magnetic field modulation linear motor for oil pumping unit

A technology of linear motors and pumping units, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of large amount of permanent magnets and high processing costs, and achieve the effects of low processing costs, convenient mechanical assembly, and high thrust density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

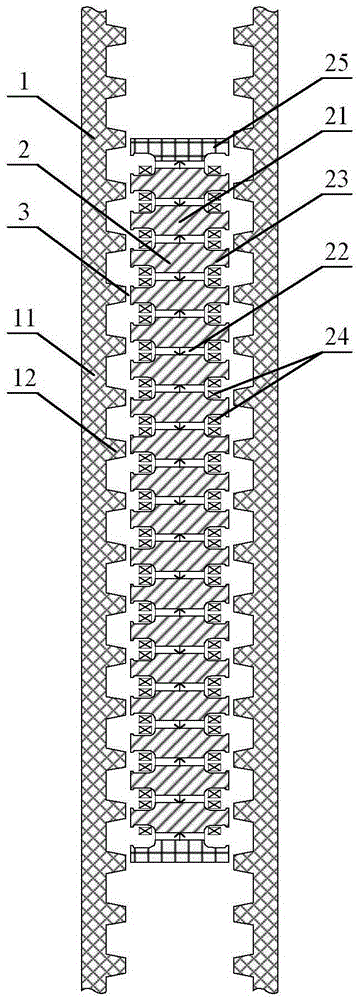

[0035] A bilateral long secondary primary permanent magnet type field modulated linear motor for an oil pumping unit, comprising two long secondary stators 1 arranged symmetrically opposite each other, and a short primary mover arranged between the two long secondary stators 1 2 and an air gap 3 provided between the short primary mover 2 and the long secondary stator 1;

[0036] The short primary mover 2 includes primary iron cores 21 arranged equidistantly along the moving direction, primary permanent magnets 22 embedded between adjacent primary iron cores 21, and the width of the primary iron cores 21 is greater than the width of the primary permanent magnets 22 Primary teeth 23 are formed on both sides of the primary iron core 21 in the width direction, and armature windings 24 are nested on the primary teeth 23 .

[0037] The long secondary stator 1 includes a flat secondary iron core 11 and secondary salient poles 12 equidistantly arranged on the inner surface of the flat...

Embodiment 2

[0040] As described in Example 1, a bilateral long secondary primary permanent magnet type field modulated linear motor for an oil pumping unit is different in that the number of primary teeth 23 on one side is: N p , The number of pole pairs wound by the armature winding 24: p w , The distance between the centers of the primary teeth 23 adjacent to one side: τ p Distance from the center of the adjacent secondary salient pole 12: τ s , satisfy the following relation (I):

[0041] N p ·τ p =(N p / 2+p w )·τ s (I)

[0042] In formula (I), N p =6k, k is a positive integer; the number of blocks of the primary permanent magnet 22 is N p +1.

Embodiment 3

[0044]A kind of bilateral long secondary primary permanent magnet field modulation linear motor for a pumping unit as described in Embodiment 1 and 2, the difference is that the end faces of the primary permanent magnets 22 at both ends of the short primary mover 2 along the moving direction Balance teeth 25 are respectively arranged on them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com