Modularized complementary type primary double-fed brushless direct-current linear motor and motor module composed by same

A linear motor and complementary technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing system cost and complexity, high system cost, and complicated control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

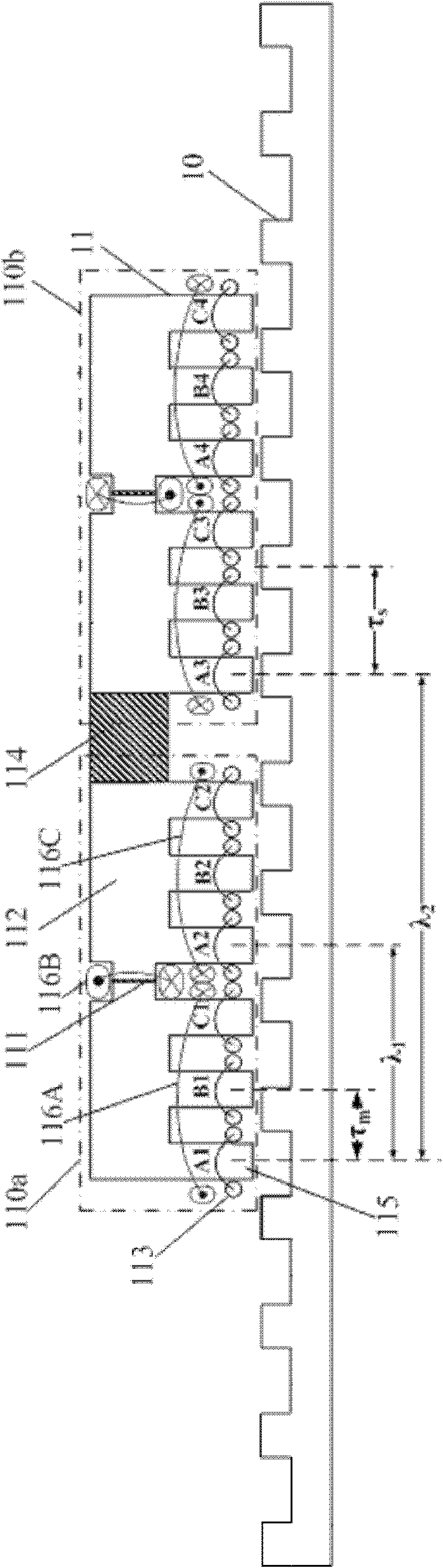

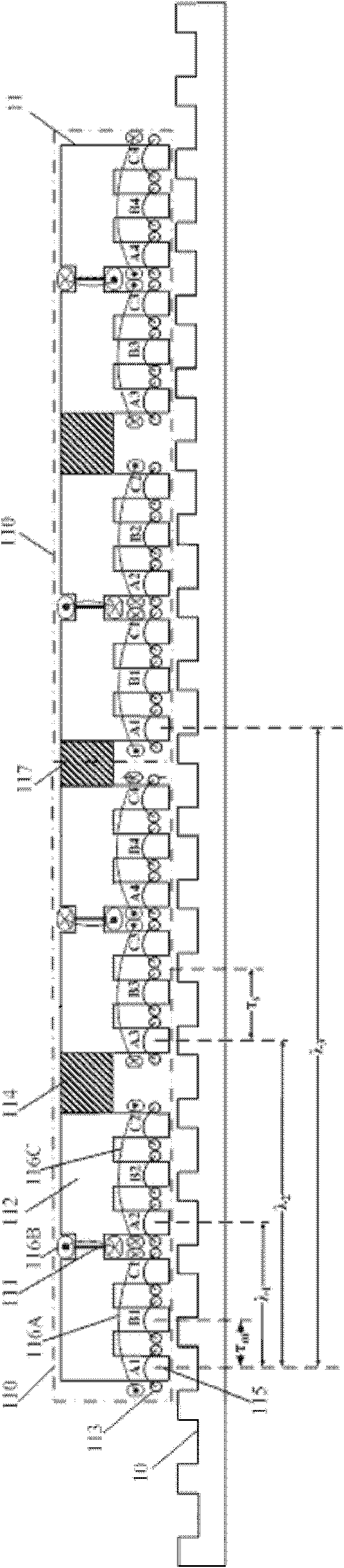

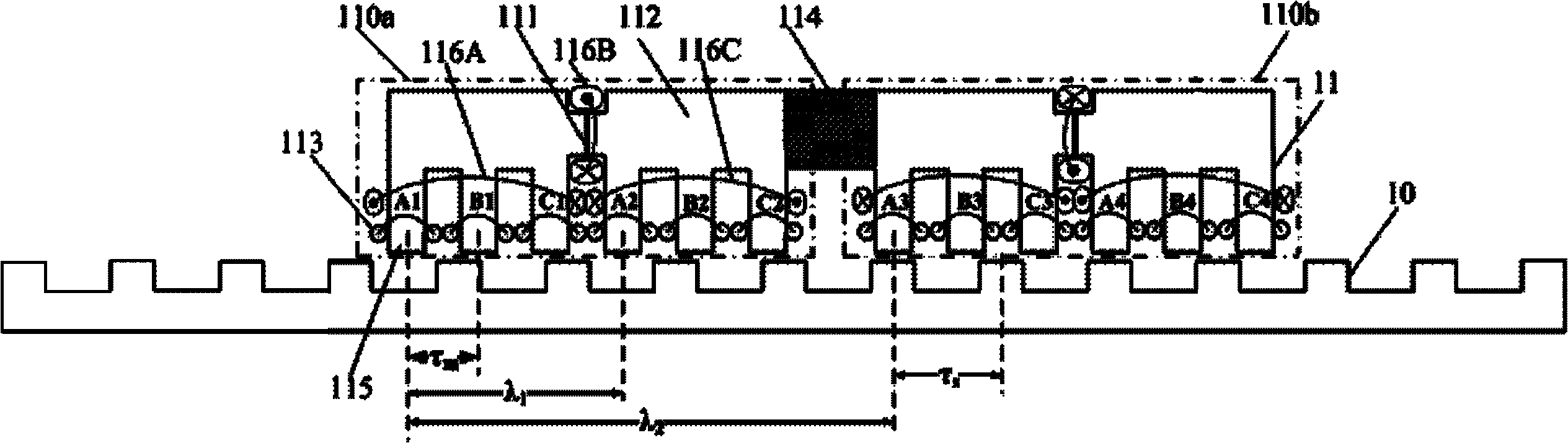

[0026] The modular complementary primary double-fed brushless DC linear motor of the present invention includes a primary 11 and a secondary 10, the primary 11 and the secondary 10 are both salient pole structures, and there is an air gap between the two. Among them, the secondary 10 has neither permanent magnets nor windings, and is only composed of low-priced straight slot or oblique slot magnetic conductive materials, making the present invention particularly suitable for long stator applications such as rail transit and high-rise building elevators. Greatly reduce the cost of the system.

[0027] The primary 11 includes a moving submodule 110, which includes a first module 110a and a second module 110b, and a first non-magnetic material 114 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com