Four-pole bearingless switched reluctance motor

A switched reluctance motor, bearingless technology, applied in the direction of electrical components, magnetic attraction or thrust holding device, etc., can solve the problems of low fault tolerance and reliability, low winding utilization rate, low slot full rate, etc., to achieve Good for heat dissipation, small moment of inertia, and small mutual inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

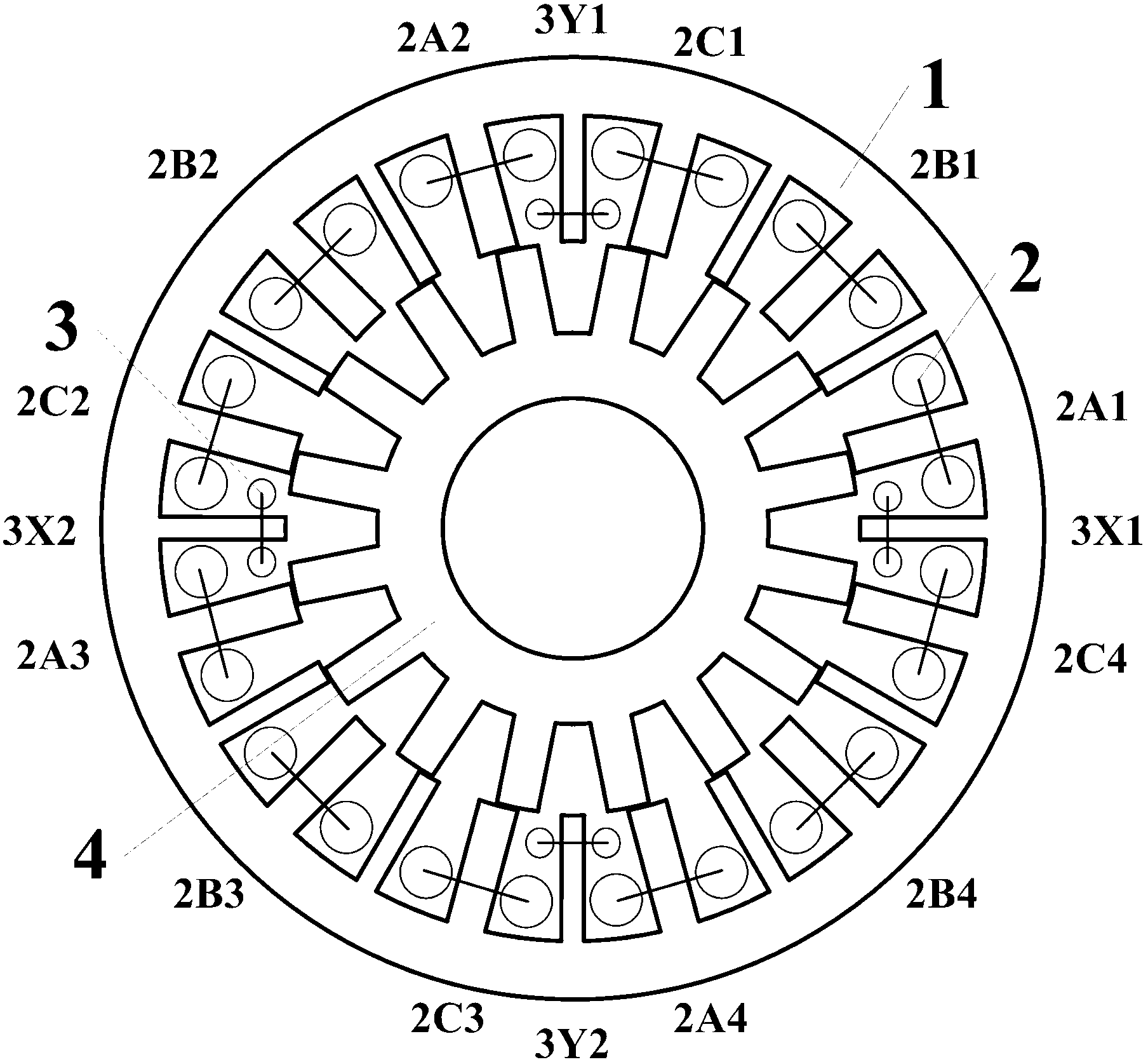

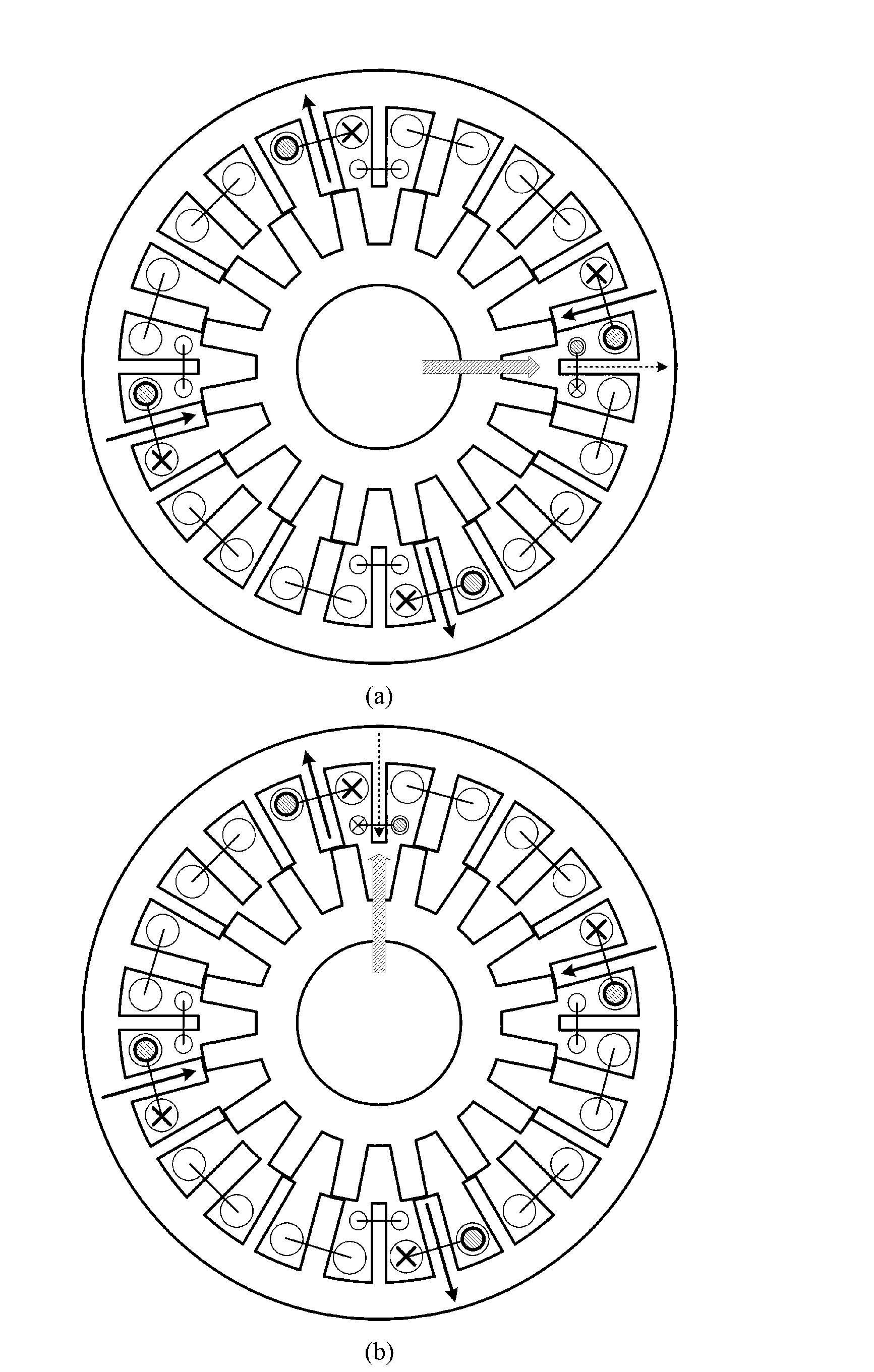

[0031] The four-pole bearingless switched reluctance motor of the present invention includes a stator 1 and a rotor 4 . The stator 1 is provided with an even number of stator teeth, which are evenly distributed, and stator slots are formed between adjacent stator teeth, and each stator tooth has another stator tooth opposite to it in the radial direction. The stator teeth can be divided into two groups with the same number, called main teeth and auxiliary teeth, which are arranged at intervals, that is, one of the two adjacent stator teeth is the main tooth and the other is the auxiliary tooth. There are concentrated windings on the stator teeth, which include torque windings 2 for outputting mechanical energy and suspension force windings 3 for suspending the rotor. The number of torque winding coils is equal to the number of main teeth of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com