Secondary tooth reciprocating scissors

A scissors and tooth-type technology, which is applied in the field of forestry machinery, can solve the problems of hedgerows and lawns such as missed cuts, and achieve the effect of avoiding missed cuts and improving the efficiency of pruning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

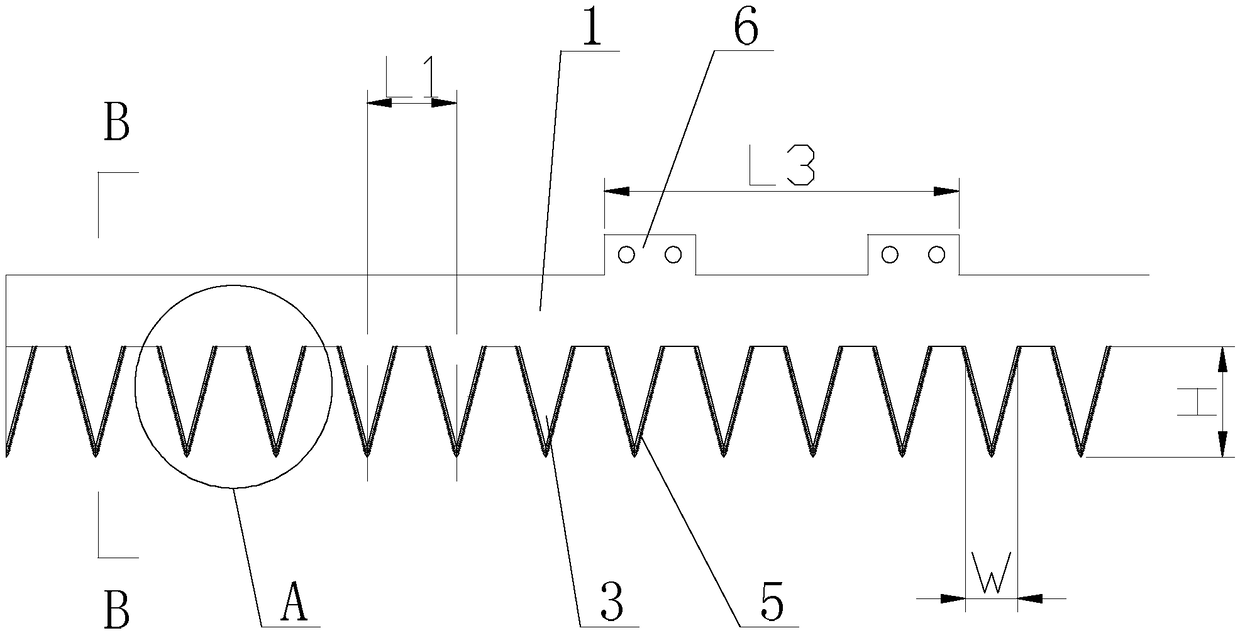

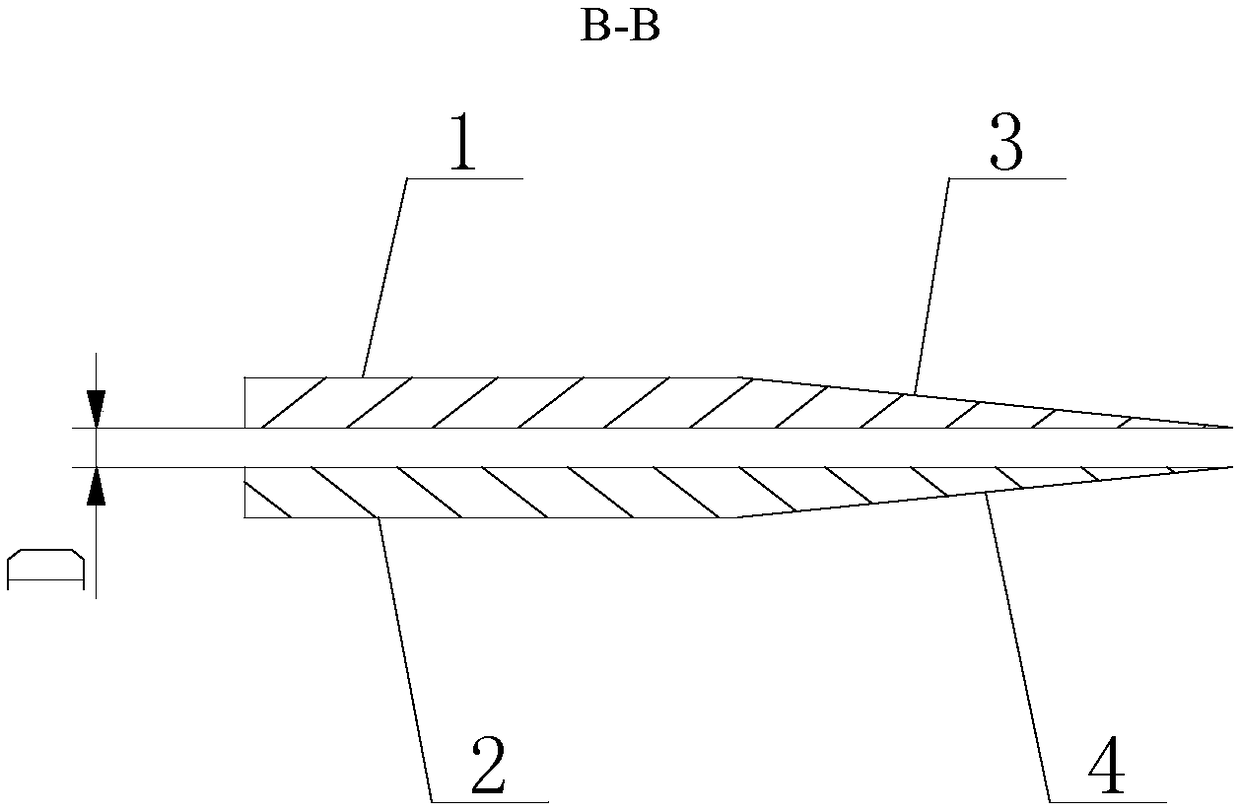

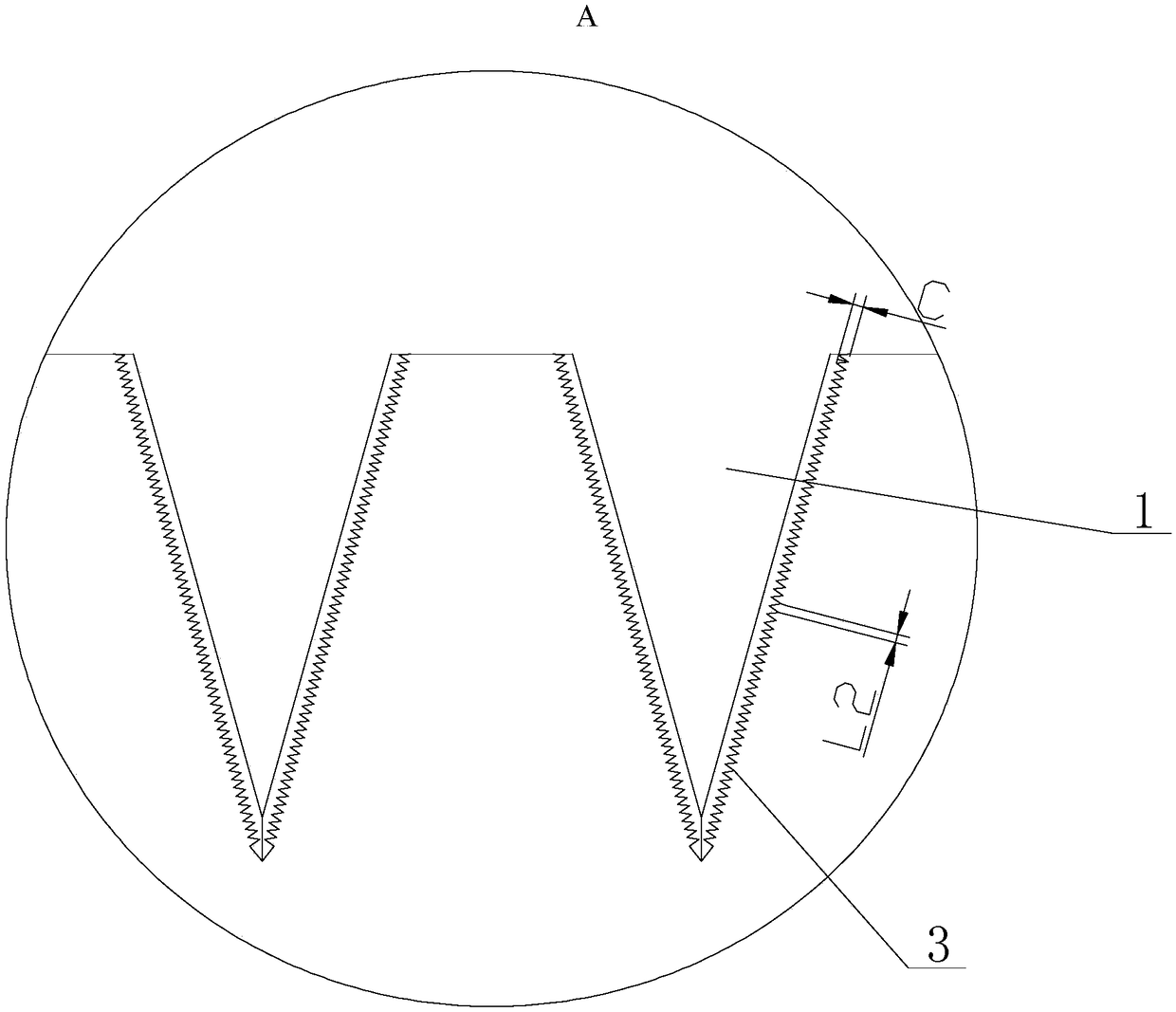

[0015] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a kind of secondary gear type reciprocating scissors described in this embodiment includes upper blade main body 1, lower blade main body 2, several upper cutting edges 3 and several lower cutting edges 4, upper blade main body 1 and lower blade main body 1 and lower blade main body 2. The blade body 2 is stacked from top to bottom, and one side of the upper blade body 1 is provided with several upper cutting edges 3 along its length direction, and each upper cutting edge 3 is connected with one side of the upper blade body 1 to form a One side, one side of the lower blade main body 2 is provided with several lower cutting edges 4 along its length direction, and each lower cutting edge 4 is connected with one side of the lower blade main body 2, and the upper cutting edge 3 and The edge of the lower cutting edge 4 is provided with several auxiliary teeth 5 .

specific Embodiment approach 2

[0016] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, the upper cutting edge 3 and the lower cutting edge 4 of a pair of auxiliary tooth type reciprocating scissors described in this embodiment are both isosceles triangles, and between the centerlines of two adjacent isosceles triangles The distance L1 is 90mm, the height H of each isosceles triangle is 115mm, and the width W of the isosceles triangle is 36.99mm. Such setting can effectively prevent the upper cutting edge 3 and the lower cutting edge 4 from slipping off due to the short length of the upper cutting edge 3 and the lower cutting edge 4, thereby providing sufficient cutting stroke. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate this embodiment, there is a gap D between the lower surface of the upper blade main body 1 and the upper surface of the lower blade main body 2 of the auxiliary tooth type reciprocating scissors in this embodiment, and the gap D is 0.5 mm. Such arrangement effectively avoids friction between the upper blade main body 1 and the lower blade main body 2, which affects the overall service life of the scissors. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com