Composite building formwork system

A technology of building formwork and composite materials, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of ineffective improvement of construction quality and safety guarantee, waste of social resources, environmental protection, reduction of construction costs and work efficiency. Improve impact and other issues to achieve the effect of smooth and beautiful building surface, saving construction cost and fine joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

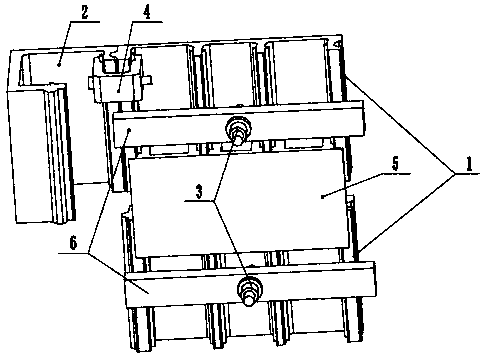

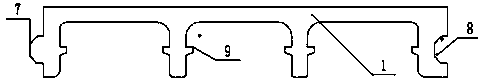

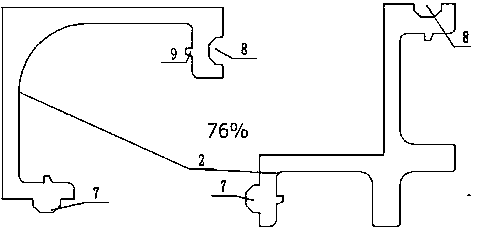

[0016] A composite material building formwork system, including a standard formwork 1, a special-shaped formwork 2, a docking fixture 3, a formwork fixture 4, a connecting plate 5, a main keel 6, a child buckle 7, a female buckle 8, a child tooth 9, and a female tooth 10 The standard formwork 1 is butted horizontally with sub-buttons 7 and female buckles 8, and the connecting plate 5 is inserted at the joint of the upper and lower rows of horizontal formwork, and the docking fixture 3 is supported between the opposite two-sided formwork, so that the thickness of the wall can be guaranteed to reach the standard size. The template fixture 4 is stuck at the junction of the two formwork child buckles 7 and female buckles 8, and is connected through the cooperation of the child teeth 9 and the female teeth 10, and the main keel 6 is supported on the outside of the connected formwork module. The seamless butt joint system of building formwork adopts two formwork flat seams to be over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com