Magnetic flux reverse linear motor

A technology of linear motors and electric motors, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of machine shutdown, permanent magnet separation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

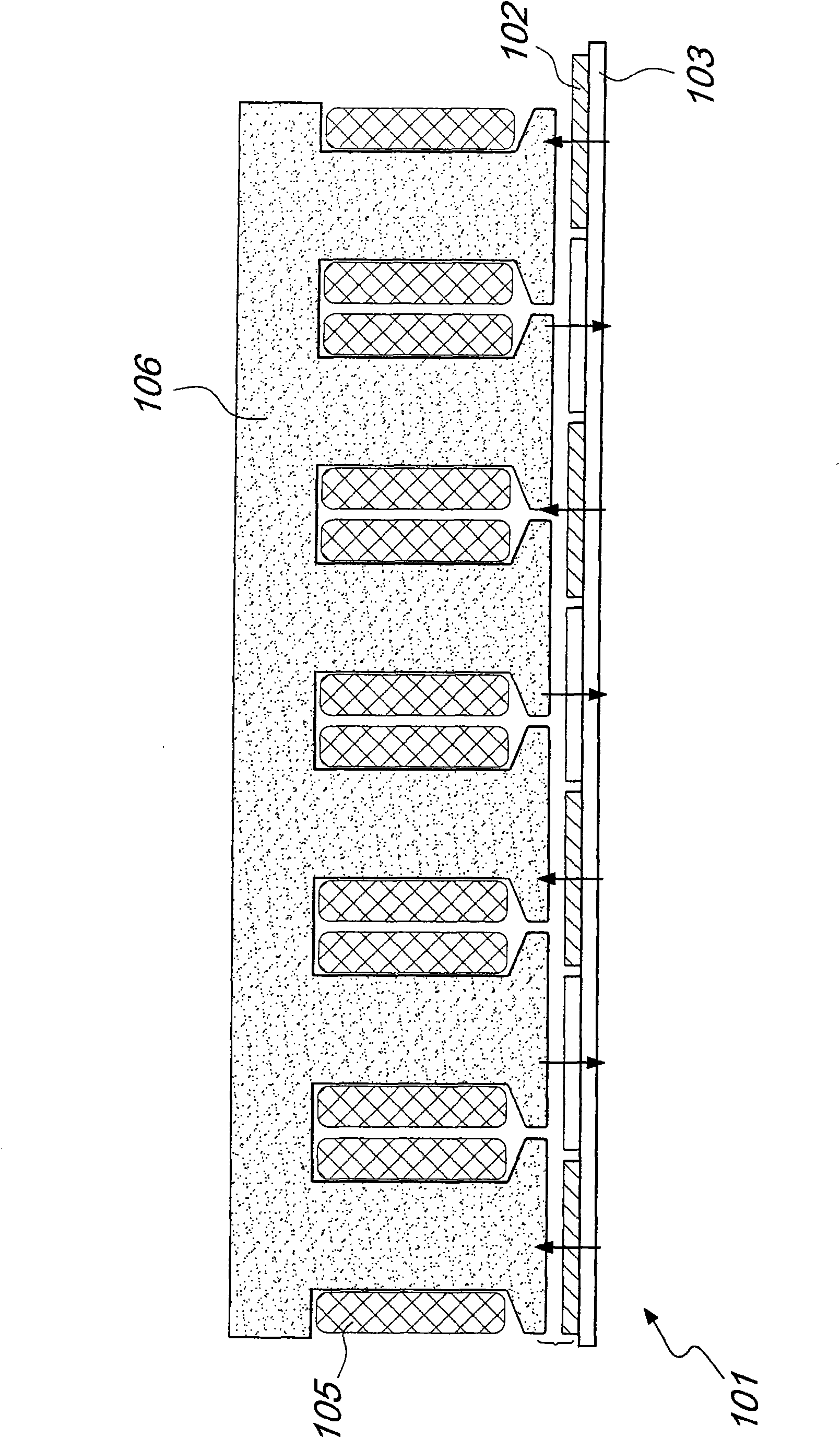

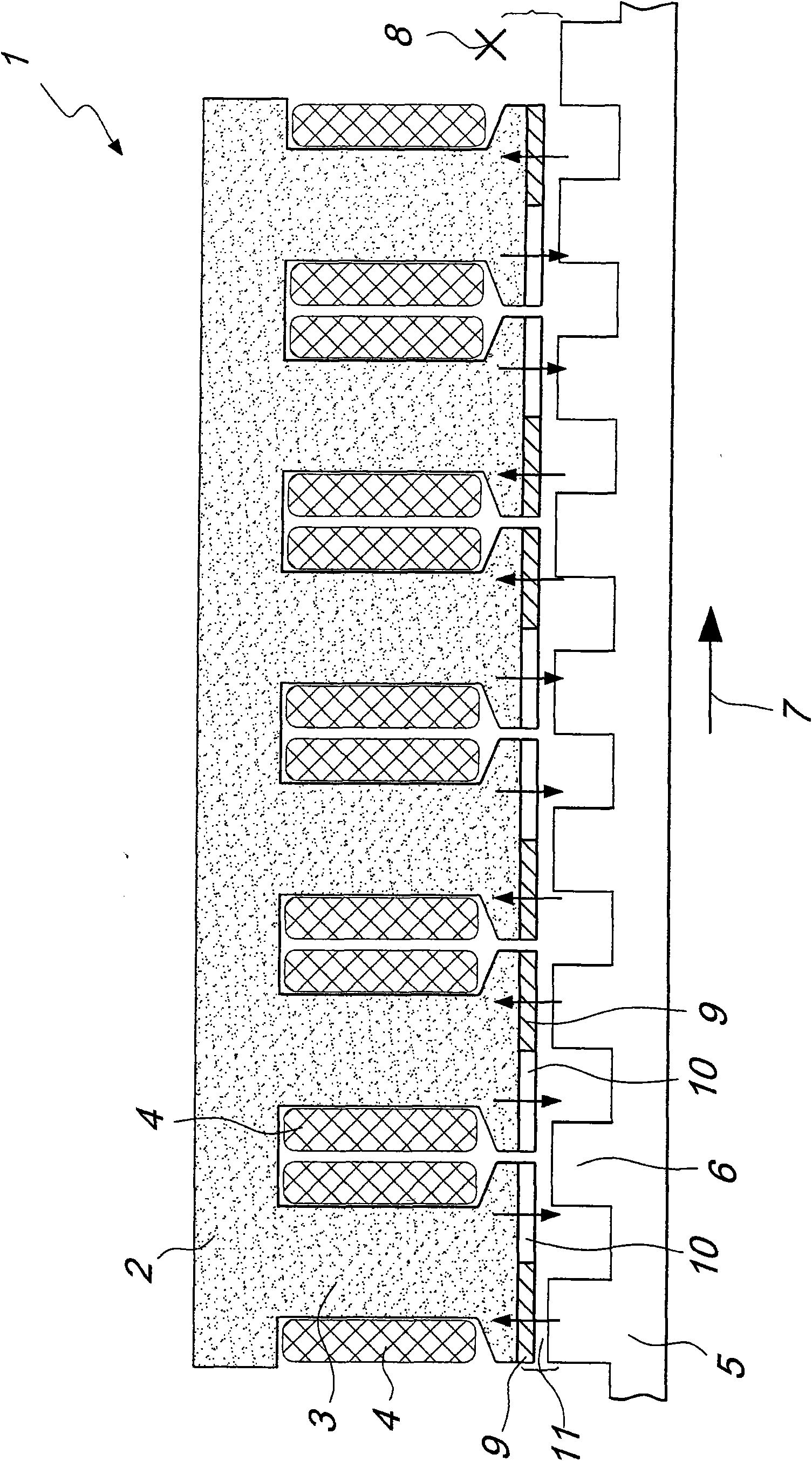

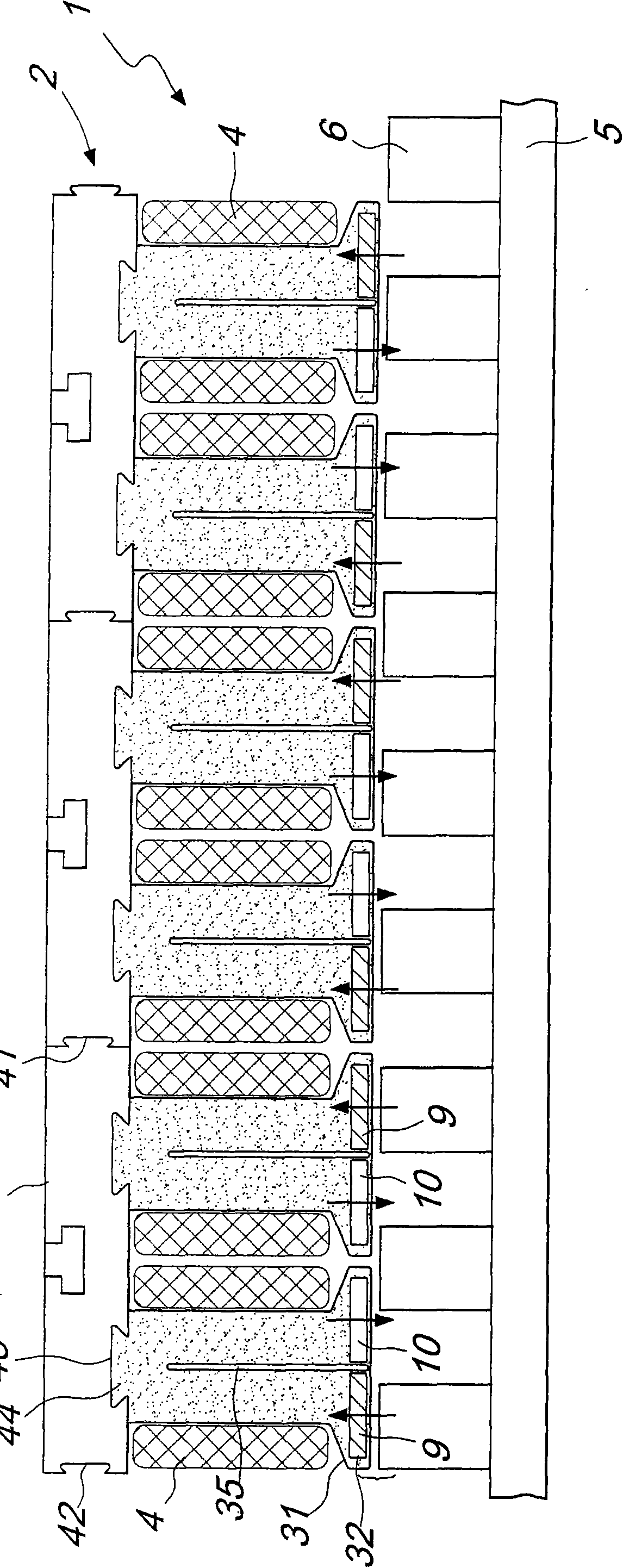

[0022] Referring to the drawings, a linear motor according to the invention, generally indicated by the reference numeral 1, comprises a primary element or stator 2, which is rectilinear and provided with at least one tooth 3, or preferably a plurality of teeth arranged side by side 3.

[0023] A corresponding coil 4 is arranged around each tooth 3 (here primary tooth) and comprises, for example, a copper coil and is connected to a conventional electronic drive not shown in the figures.

[0024] Preferably, the primary element 2 consists of a plurality of ferromagnetic laminations, which have the same shape and are stacked to form a lamination assembly with the teeth-like structure of the primary element 2 as shown.

[0025] The linear motor 1 also comprises a toothed secondary element 5 made of ferromagnetic material, which is flat and faces the teeth 3 of the primary element.

[0026] The primary and secondary elements are conventionally mounted on a structure (not shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com