A double-sided alternating-pole permanent magnet linear motor with secondary yokeless section

A technology of permanent magnet linear motor and alternating poles, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reducing the utilization rate of permanent magnet materials, increasing the cost and weight of the system, and low utilization rate of permanent magnets, so as to improve the Effects of thrust density and permanent magnet utilization, cost and weight reduction, and risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

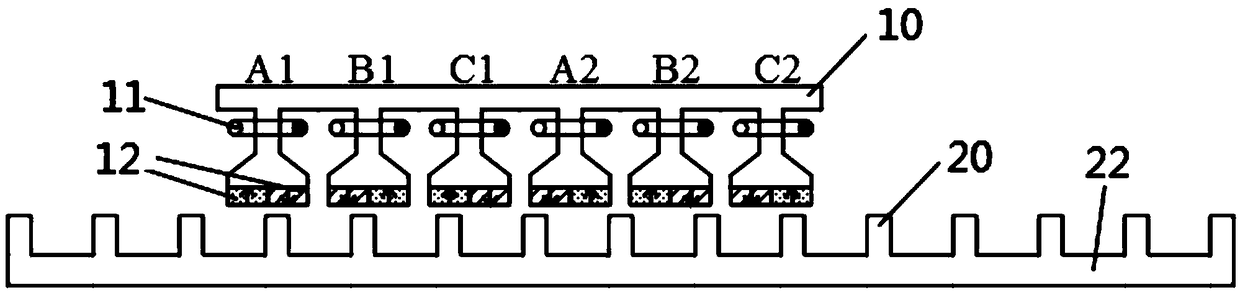

[0044] Embodiment 1: The positions of the tooth top surfaces where the permanent magnets on both primary sides are located are the same, and the magnetization directions of the primary permanent magnets on both sides are the same.

Embodiment 2

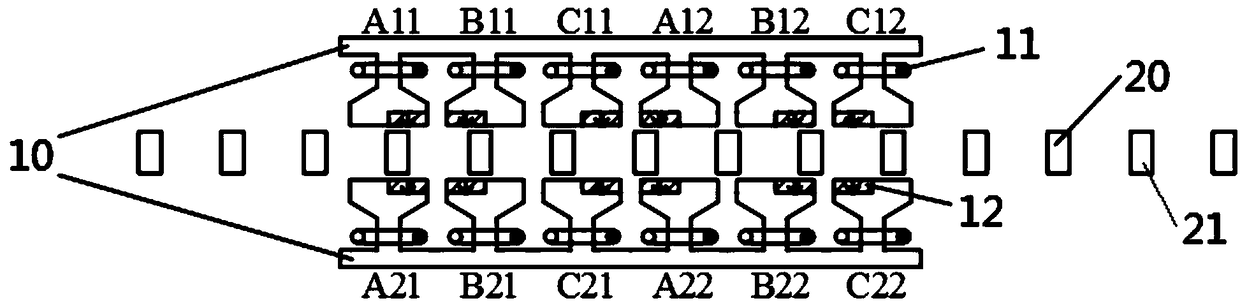

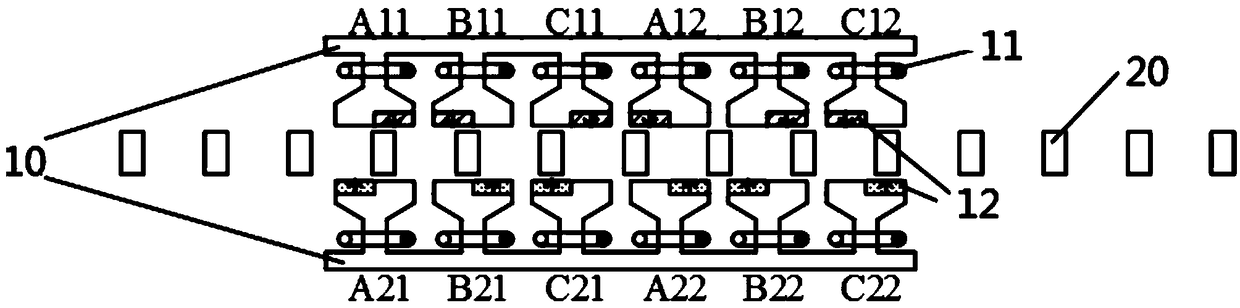

[0045] Embodiment 2: The permanent magnet on the top surface of the primary tooth on one side faces the salient pole of the iron core on the top surface of the primary tooth on the other side, and the magnetization directions of the primary permanent magnets on both sides are opposite.

[0046] You can choose long primary or long secondary according to application needs. figure 2 and image 3 for the long secondary, Figure 4For long primary. Among them, the long stage is the stator, and the short stage is the mover. When the primary is a long primary and a stator, and the secondary is a mover, the dynamic response capability of the secondary mover can be improved, and the cost of the primary stator can be reduced (improving the utilization rate of the permanent magnet). When the secondary is a long secondary and is a stator, and the double primary is a mover, the cost can be reduced (the mover has no permanent magnets and windings).

[0047] The following takes a 3-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com