Tooth-slot salient permanent magnet composite array linear motor

A composite array and linear motor technology, applied in the field of electromagnetic devices, motors and electrical appliances, can solve the problems of high cost, low power index, large volume, etc., to eliminate magnetic flux leakage, reduce volume and manufacturing cost, increase power and output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

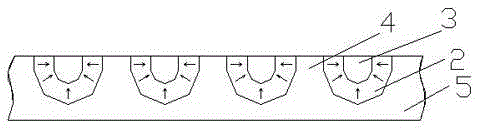

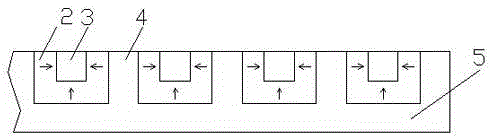

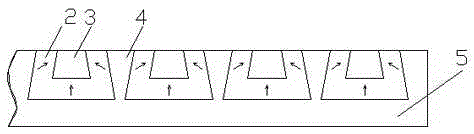

[0048] Such as Figure 1-Figure 13As shown, the cogged salient pole permanent magnet array is composed of at least one set of cogged salient pole permanent magnet composite array units mounted sequentially, and the cogged salient pole permanent magnet composite array unit is composed of slot convex iron 3, magnet array 2 1. Composed of an iron core, the iron core is provided with grooves, the two sides of the grooves are teeth protrusions 4, the rest is the yoke 5, the groove protrusions 3 are located in the middle of the groove and are close to the outer surface of the magnet array 2 The magnet array 2 is composed of at least one group of magnets around the groove mounted along the inner wall of the groove. The magnet array 2 gathers magnetic poles with the same polarity on the surface of the protruding iron 3 at the groove portion, and forms poles on the surface of the protruding iron 4 at the tooth portion. opposite magnetic poles. The iron cores in the adjacent alveolar s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com