Low-thrust-fluctuation continuous pole permanent magnet synchronous linear motor

A permanent magnet synchronous linear, low-thrust technology, applied in electrical components, electromechanical devices, propulsion systems, etc., can solve the problems of continuous pole permanent magnet synchronous linear motor thrust fluctuations, etc., to suppress even harmonics, reduce volume and mass , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

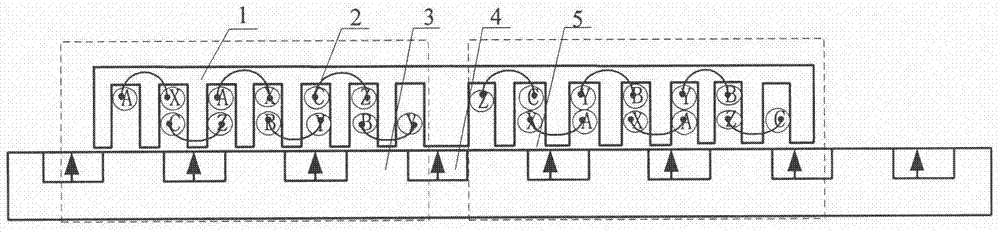

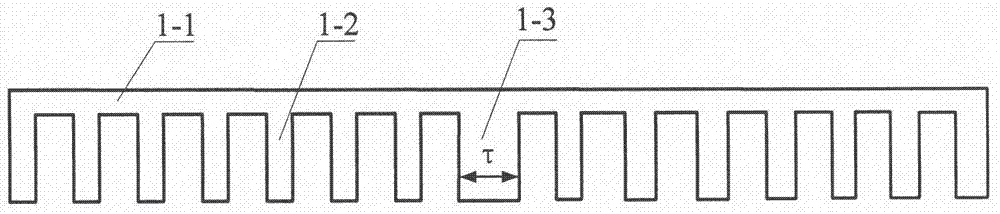

[0020] Such as figure 1 , 2 , 3, and 4, this embodiment is a unilateral flat-plate type low-thrust fluctuation continuous pole permanent magnet synchronous linear motor, and its pole slots are matched to a 10-pole 12-slot structure, which is composed of two 5-pole 6-slot unit motors, including a Primary assembly, one secondary assembly and air gap. The primary assembly consists of the primary core 1 and the armature winding 2. The primary iron core is slotted to form a primary yoke 1-1, a primary tooth 1-2 and a magnetic modulation structure 1-3. The magnetic modulation structure 1-3 is located between the unit motor 1 and the unit motor 2, and is integrated with the primary iron core 1-1. The width of the magnetic modulation structure is τ (τ is the pole pitch). The winding directions of the A-phase winding 2-1-1 on the unit motor 1 and the unit motor 2 2-1-2 are opposite. Similarly, the winding directions of the B-phase windings 2-2-1 and 2-2-2 and the C-phase winding 2...

Embodiment approach 2

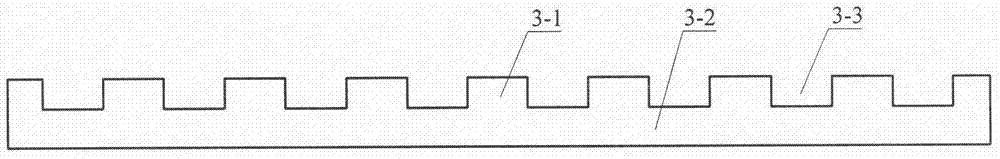

[0023] Such as Figure 5 As shown, the difference between the present embodiment and the first embodiment is that the magnetic modulation structure 1-3 adopts a slotted structure to form a magnetic modulation groove 1-3-1 and a magnetic modulation tooth 1-3-2, and a magnetically conductive material is used. Form an integral structure with the primary core 1, the value range of the width s of the magnetic adjustment slot 1-3-1 is 0≤S≤τ, and the value range of the height h of the magnetic adjustment tooth 1-3-2 is: 0≤h≤ H, H is the height of primary teeth 1-2. Through the flexible optimal design of the height and width of the magnetic field slot 1-3-1 and the magnetic field tooth 1-3-2, the optimal design of the magnetic field can be further realized, and the three-phase winding caused by the end effect of the linear motor can be improved. Symmetry is further conducive to reducing thrust fluctuations and increasing average thrust.

Embodiment approach 3

[0025] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the low-thrust fluctuation continuous pole permanent magnet synchronous linear motor adopts a multi-unit motor structure design, n (n≥2) unit motors form a module, and the magnetic modulation structure 1-3 Set between two modules. The winding directions of the windings of different modules are opposite. For the multi-pole and multi-slot high-thrust linear motor structure, this structure can achieve the effect of suppressing even-order harmonics with only a small number of magnetic modulation blocks, thereby reducing the length of the primary and increasing the thrust density of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com