Silk composite fabric production method

A composite fabric and production method technology, applied in the direction of enzyme/microbial biochemical treatment, biochemical fiber treatment, improved hand feeling fiber, etc., can solve the problems of insufficient performance of other fabrics, uneven soaking of fabrics, etc., and achieve excellent wrinkle resistance, Improve the effect of application value, good elasticity and elastic recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of silk composite fabric, its production method comprises the steps:

[0038] (1) Spinning: blending bamboo fiber and ramie fiber to make bamboo fiber-ramie fiber blended yarn, softening with acid cellulase, the acid cellulase consumption is 3% of the quality of bamboo fiber-ramie fiber blended yarn , the pH value is 4.8, the temperature is 55°C, and the treatment time is 60min;

[0039] (2) Silk production: take spandex filament as the core thread, wrap the silk on the outside of the spandex filament in a spiral shape through the wrapping process, and make silk-spandex coated filament;

[0040] (3) weaving: take the bamboo fiber-ramie fiber blended yarn processed in the step (1) as the weft, and the silk-spandex covered silk made in the step (2) as the warp, weave to obtain the composite gray silk;

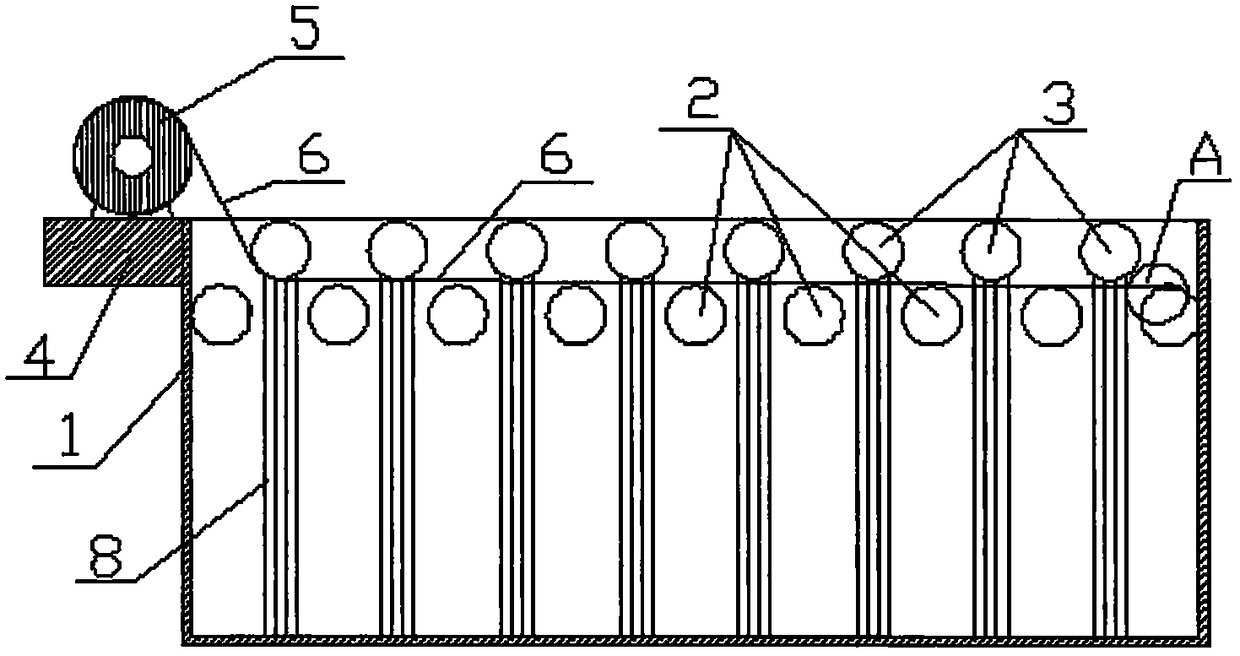

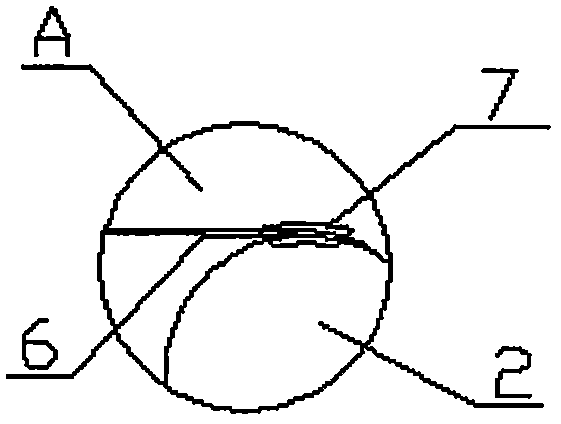

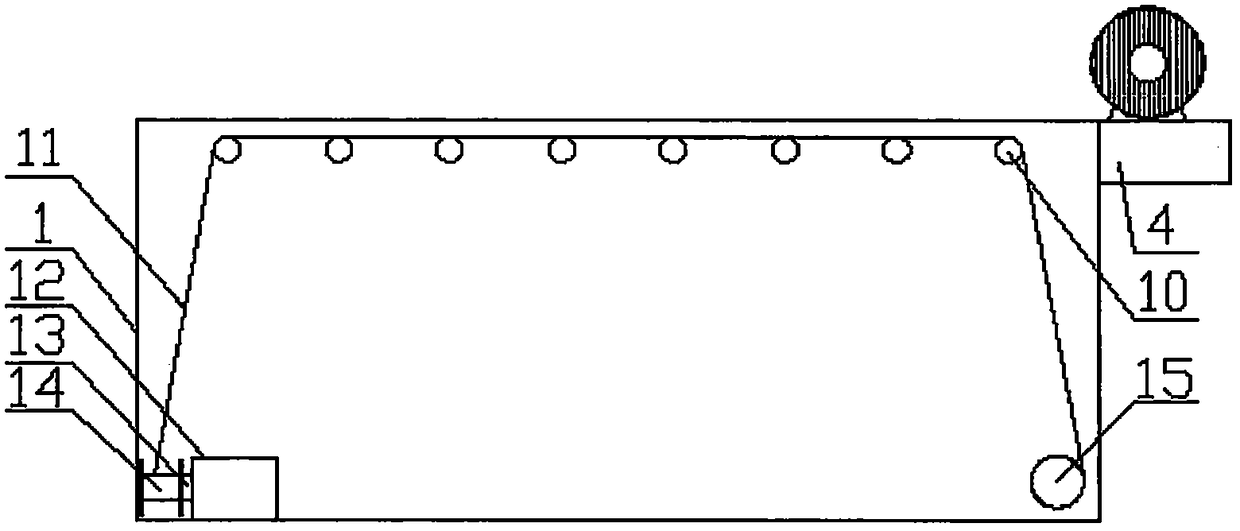

[0041] (4) Refining: immerse the composite gray silk obtained in step (3) into a soaking device equipped with a mixed solution of soap and sodium carbonate, heat, ...

Embodiment 2

[0051] A kind of silk composite fabric, its production method comprises the steps:

[0052] (1) Spinning: blending bamboo fiber and ramie fiber to make bamboo fiber-ramie fiber blended yarn, carry out softening treatment with acid cellulase, and the acid cellulase consumption is 2.5% of the quality of bamboo fiber-ramie fiber blended yarn , the pH value is 4.8, the temperature is 53°C, and the treatment time is 55min;

[0053] (2) Silk production: take spandex filament as the core thread, wrap the silk on the outside of the spandex filament in a spiral shape through the wrapping process, and make silk-spandex coated filament;

[0054] (3) weaving: take the bamboo fiber-ramie fiber blended yarn processed in the step (1) as the weft, and the silk-spandex covered silk made in the step (2) as the warp, weave to obtain the composite gray silk;

[0055] (4) Refining: immerse the composite gray silk obtained in step (3) into a soaking device equipped with a mixed solution of soap an...

Embodiment 3

[0063] A kind of silk composite fabric, its production method comprises the steps:

[0064] (1) Spinning: blending bamboo fiber and ramie fiber to make bamboo fiber-ramie fiber blended yarn, softening treatment with acid cellulase, the acid cellulase consumption is 2% of the quality of bamboo fiber-ramie fiber blended yarn , the pH value is 4.8, the temperature is 50°C, and the treatment time is 50min;

[0065] (2) Silk production: take spandex filament as the core thread, wrap the silk on the outside of the spandex filament in a spiral shape through the wrapping process, and make silk-spandex coated filament;

[0066] (3) weaving: take the bamboo fiber-ramie fiber blended yarn processed in the step (1) as the weft, and the silk-spandex covered silk made in the step (2) as the warp, weave to obtain the composite gray silk;

[0067] (4) Refining: immerse the composite gray silk obtained in step (3) into a soaking device equipped with a mixed solution of soap and sodium carbona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com