Two flywheels for dry type dual clutch

A dual-clutch and clutch technology, applied in the direction of clutches, friction clutches, mechanically driven clutches, etc., can solve problems such as difficulty in ensuring coaxiality, achieve easy maintenance, simple structure, and eliminate installation inconvenience and installation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

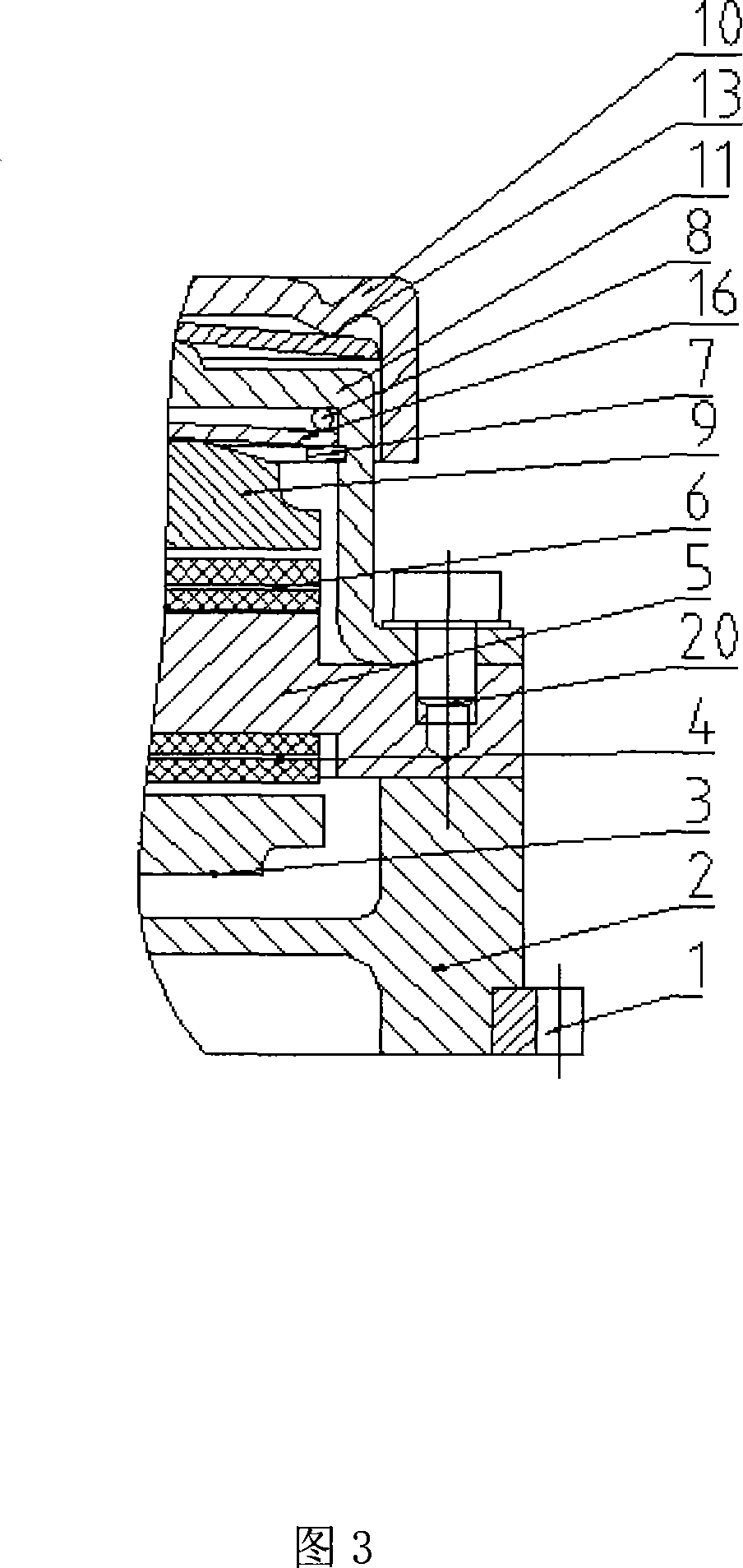

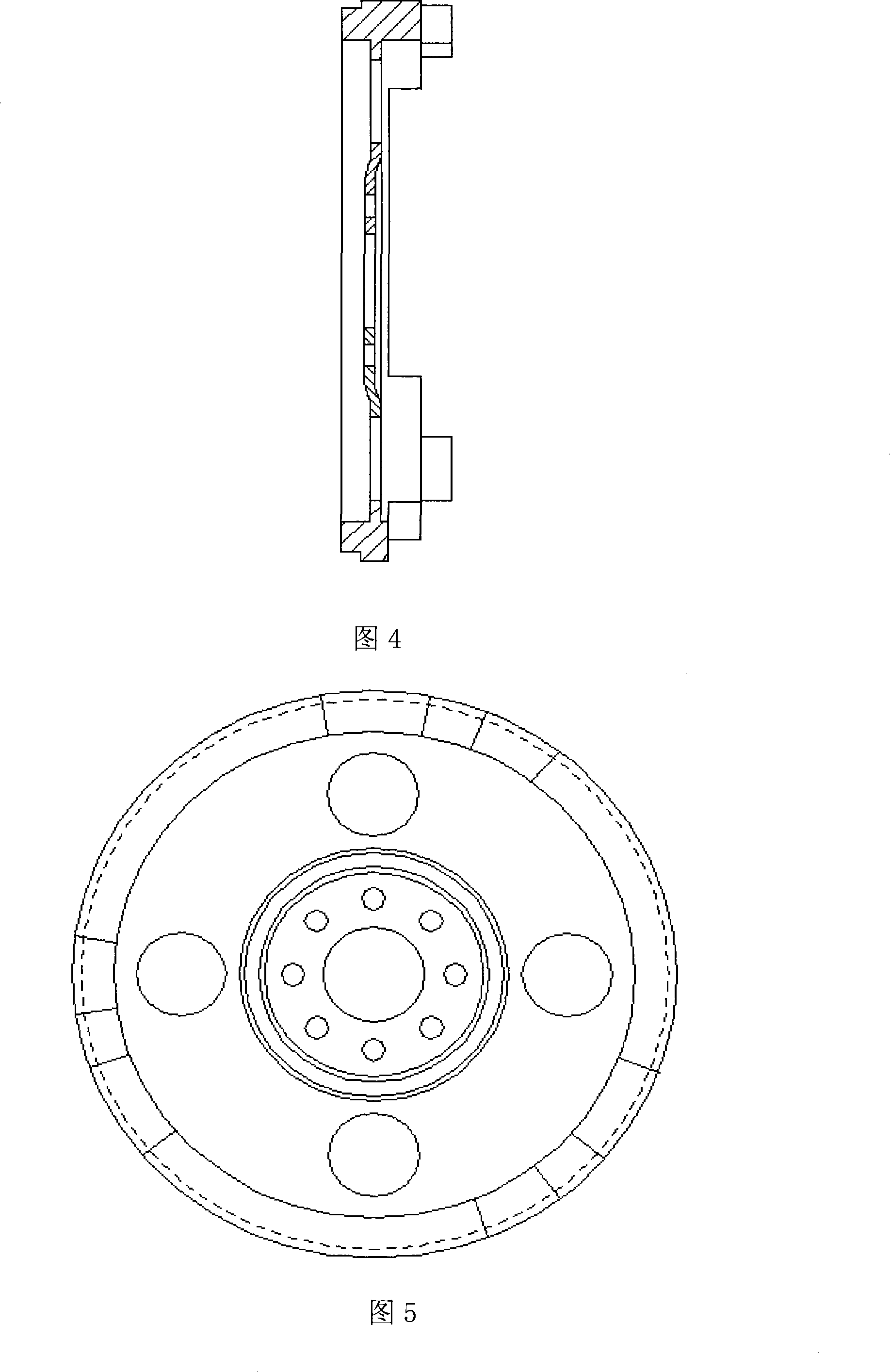

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

[0028] Referring to Fig. 4 to Fig. 6, the flywheel 2 provided by the present invention is a disk-shaped piece composed of a rim, spokes and a hub, and the center of the hub is processed with a flange set on the crankshaft output end of the engine 21 A large-diameter flange through hole, 8 identical bolt through holes for mounting bolts for fixed connection with the flange are evenly distributed around the flange through hole, and 8 identical bolt through holes There are 4 heat dissipation through holes for weight reduction and heat dissipation evenly distributed around, on the right end surface of the rim (the left end surface, right end surface, left side and right side mentioned in the application documents are all referred to in Figure 2 The working position after being installed in the center) is processed along the radial direction and has three meshing teeth 28 used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com