Press fitting tool for fitting electromagnetic ferromagnetic yoke on bottom plate in pressing mode

A press-fit tooling and electromagnet technology, which is applied in the field of press-fit tooling, can solve problems such as low press-fit efficiency, machine head injury, and simple structure, and achieve the effects of improving efficiency, convenient operation, and high operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

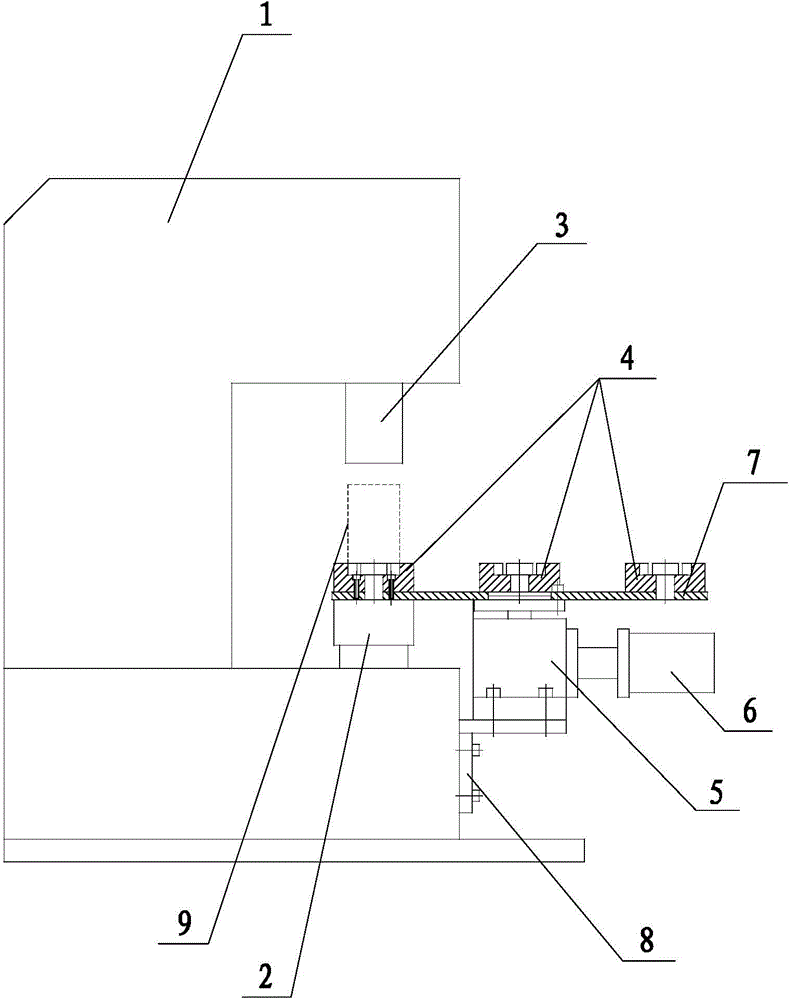

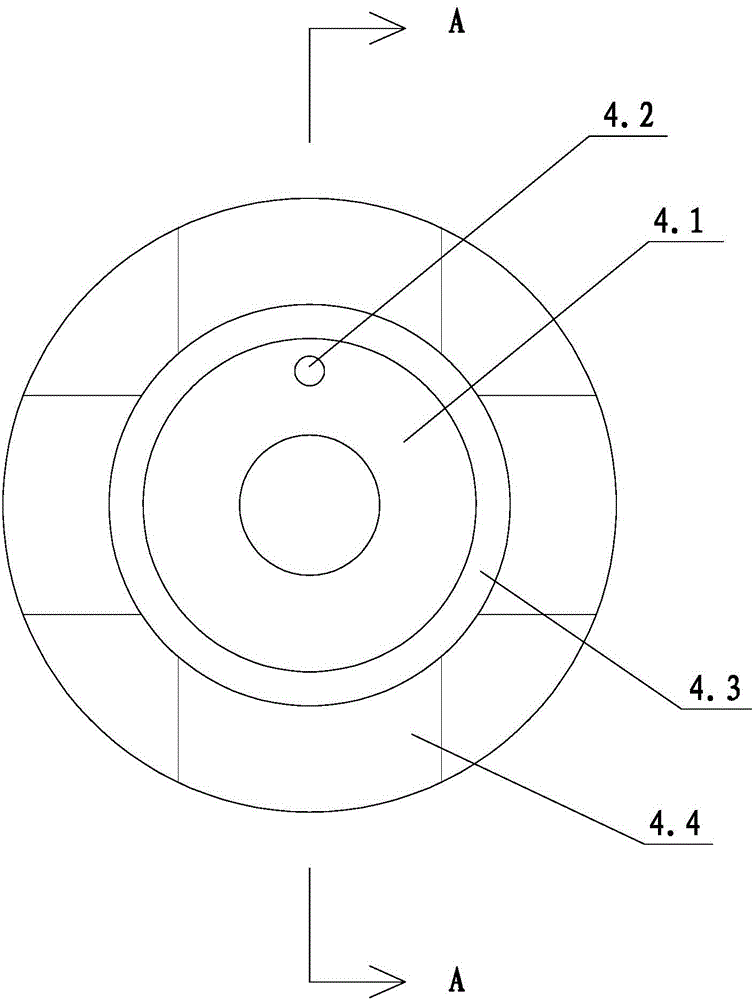

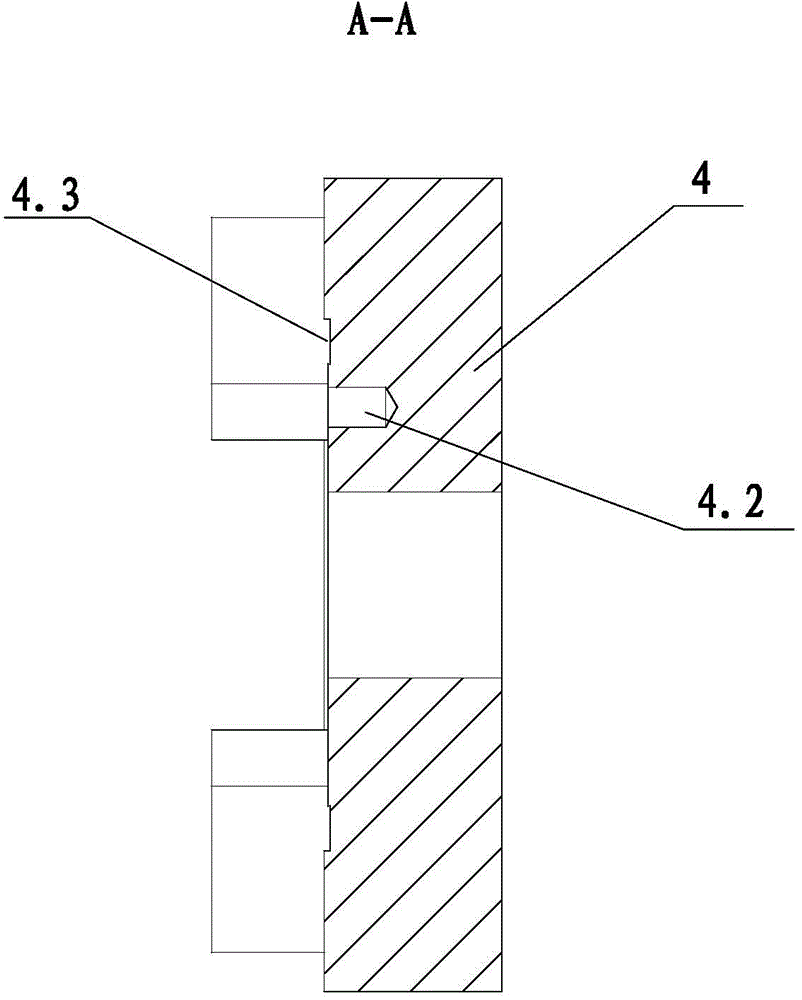

[0016] see figure 1 , figure 2 and image 3 As shown, the press-fitting tool for press-fitting the electromagnet yoke on the base plate of the present invention includes a hydraulic machine tool 1 and a rotary part positioning device. The hydraulic machine tool 1 is provided with a base 2 and a moving ram 3 . The function of the moving pressure head 3 is to press-fit the yoke 9.1 and the bottom plate 9.2. The base 2 plays a role of supporting the yoke 9.1 and the bottom plate 9.2 during press fitting. The base 2 is arranged directly below the moving pressure head 3 . The rotary part positioning device includes a plurality of positioning seats 4 for positioning the yoke 9.1 of the electromagnet 9 and the bottom plate 9.2. The rotation of the rotary parts positioning device can alternately send a plurality of positioning seats 4 between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com