Carpenter saw

A technology of woodworking saws and saw blades, which is applied to wood processing appliances, circular saws, manufacturing tools, etc., can solve problems such as maintenance, installation difficulties, complex structures, and reduced wood processing quality, so as to improve processing quality, eliminate installation errors, The effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

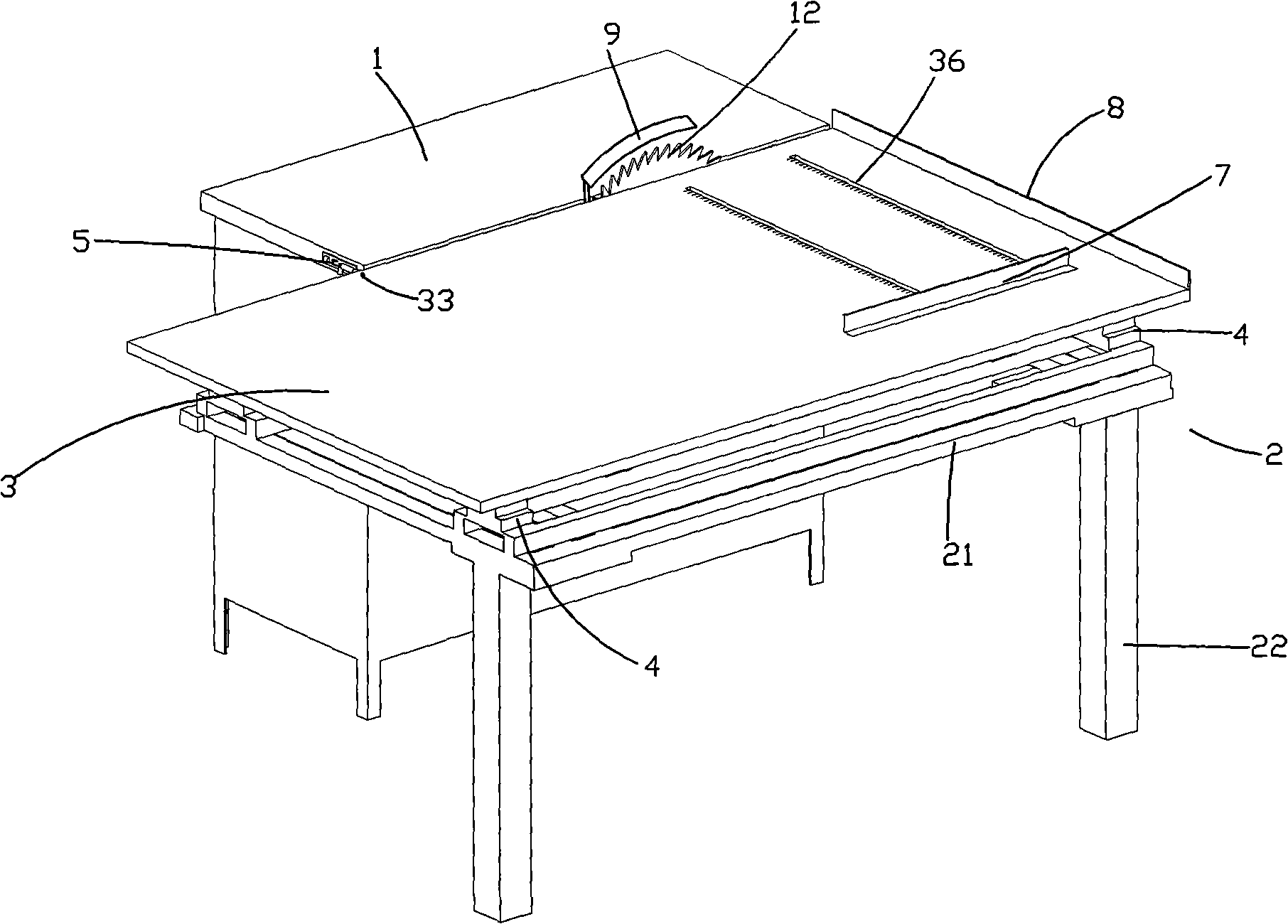

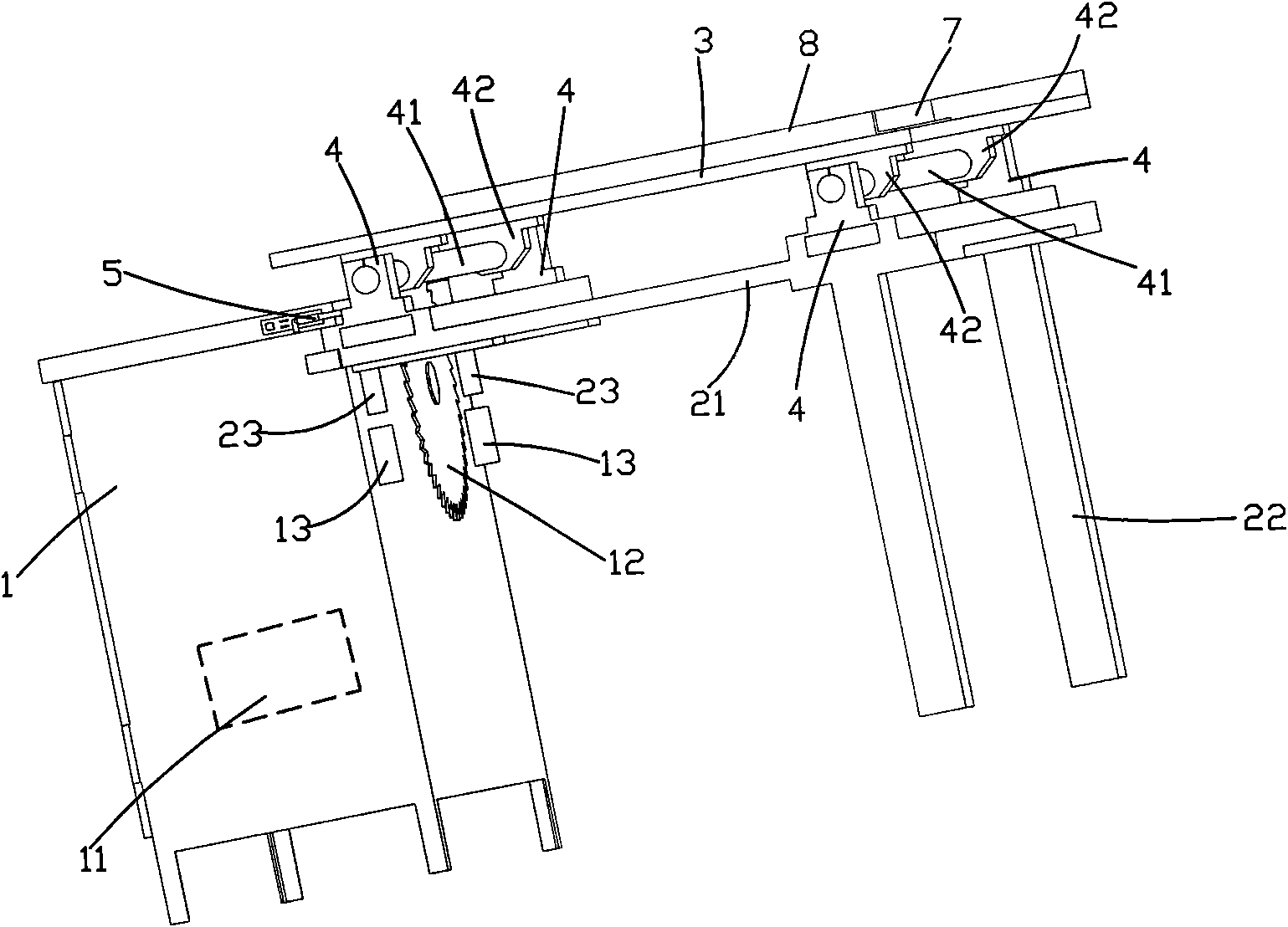

[0019] refer to figure 1 , figure 2 According to a woodworking saw mentioned in the present invention, it comprises a power box 1, a bracket 2 and a workbench 3. A motor 11 is installed inside the power box 1, and a saw blade 12 driven by the motor 11 is provided at the right end of the power box 1. The right end of the power box 1 is welded with a The connecting sleeve 13, the upper end of the bracket 2 is equipped with at least two vertically parallel sliding rods 41 through the support 4, and each sliding rod 41 is sleeved with at least two slidable linear bearings 42, and the workbench 3 is fixedly installed On the linear bearing 42, and slide on the slide bar 41 through the linear bearing 42, when the worktable 3 slides, the linear bearing 42 can follow the workbench 3 in real time to move, ensuring the distance between the linear bearing 42 and the slide bar 41 during sliding. Good cooperation can effectively reduce vibration and improve the processing quality of wood....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com