A high-precision drilling and nail feeding device

A high-precision, nail-feeding technology, applied in positioning devices, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as single function, low integration, and difficulty in meeting normal positioning requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

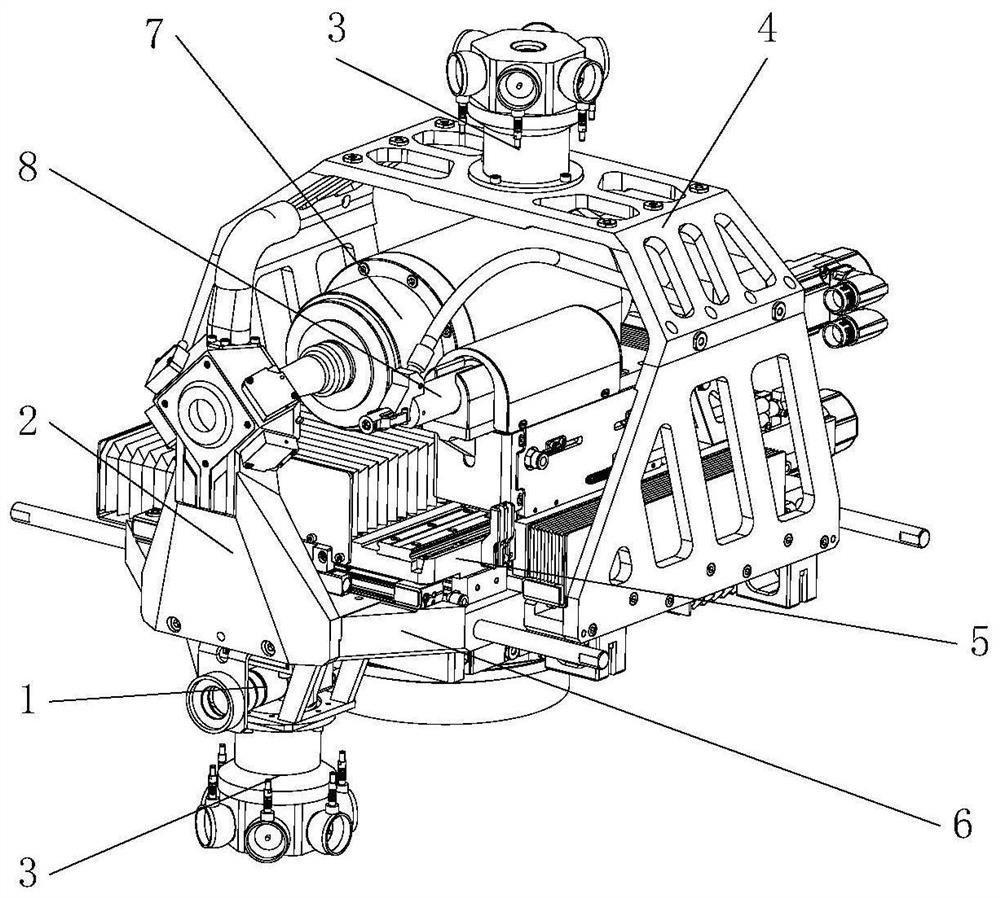

[0037] Such as figure 1 As described above, a high-precision drilling and nail feeding device of the present invention includes: a photometric measurement component 1, a non-contact normal direction detection component, a pressing component 2, a pressure measurement component, a 6D pose feedback component 3, an auxiliary measurement component 4, Station conversion component 5, X-direction feed component 6, drilling component 7, nail feeding component 8, control system, etc.

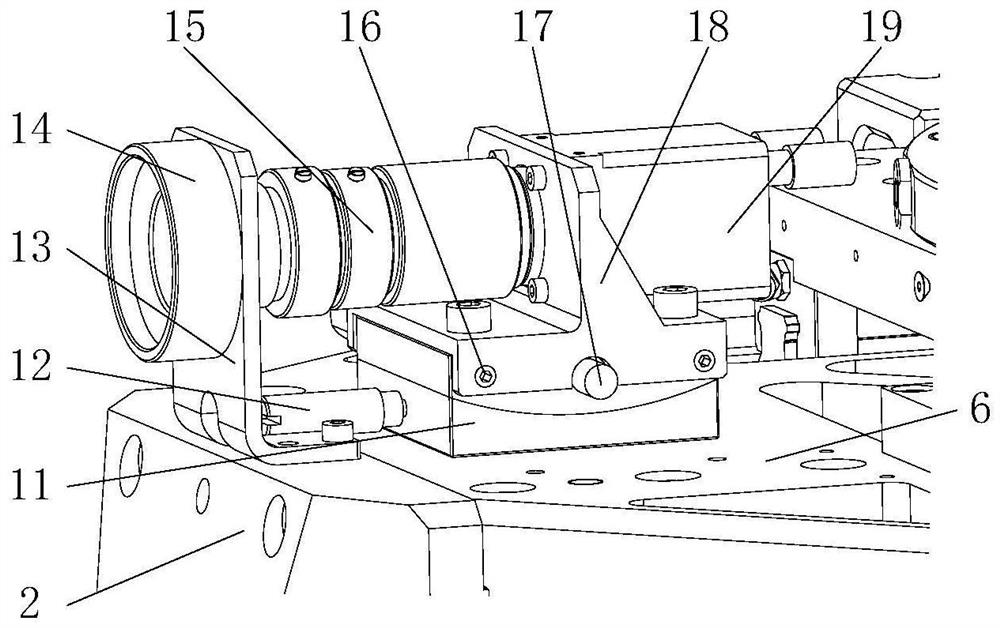

[0038] Such as figure 2As shown, the camera measurement assembly is composed of an attitude adjustment base 11, an attitude adjustment rod 12, a light source support frame 13, a camera light source 14, a camera lens 15, an attitude adjustment screw 16, a locking lever 17, a camera support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com