A pulsed laser single event effect back-irradiation positioning method

A single-event effect, pulsed laser technology, which is applied in the direction of single semiconductor device testing, instruments, measuring devices, etc., can solve the problem that the position coordinates of the back and front of the die cannot be converted to each other, and cannot fully meet the needs of pulsed laser back irradiation positioning. , can not form back sensitive nodes and other problems, to achieve the effect of saving purchase and transformation costs, reducing experimental costs, and reducing the difficulty of pretreatment and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

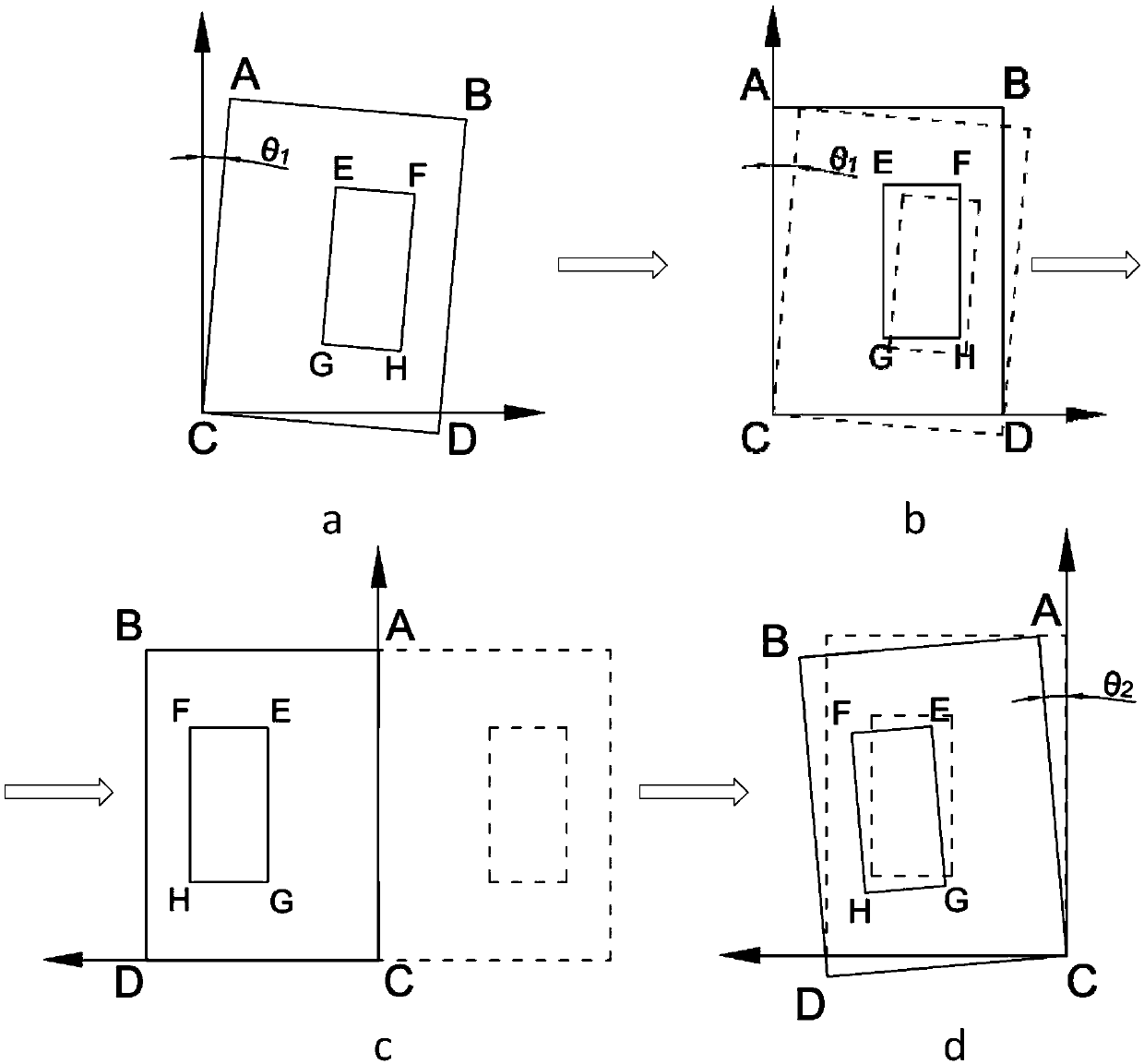

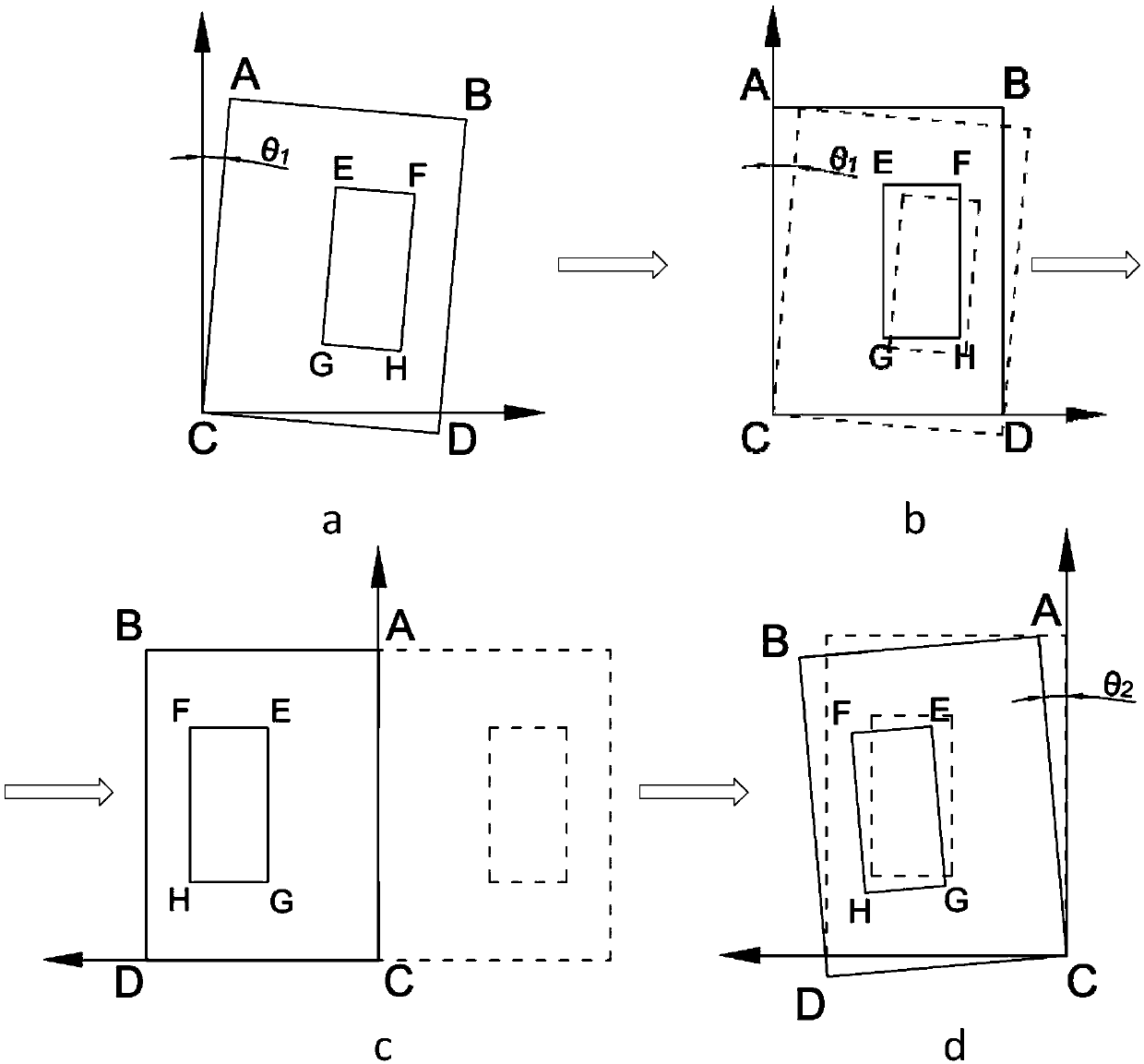

[0031] figure 1 The transformation operation steps for the die and the planar view of the area to be tested are given:

[0032] (1) Use the three-dimensional mobile platform control software to obtain the coordinate values of the four vertices A, B, C, and D on the front of the tube core and the four vertices E, F, G, and H of the area to be tested. According to the coordinate values, use AutoCAD to make the tube Core front plan view, as in figure 1 Shown in a.

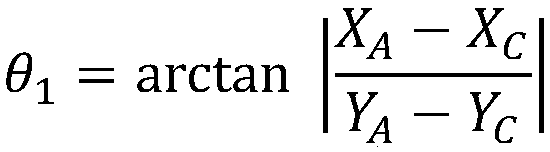

[0033] (2) According to the actual coordinates of A and C obtained in (1), calculate the angle θ between AC and the Y axis 1 , and according to θ 1 Rotate the planar graph to a position orthogonal to the coordinate axes, such as figure 1 Shown in b. Angle θ between AC and Y axis 1 The calculation formula is:

[0034]

[0035] where X A 、X C and Y A , Y C They are the abscissa and ordinate of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com