Quenching inductor for double steps of steering joint and quenching method for steering joint

A technology for quenching inductors and steering knuckles, which is applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., and can solve the problems of uniform effective hardened layer, difficulty in continuous distribution, high requirements for inductor manufacturing precision, and difficulty in process adjustment, so as to avoid early Effects of burning loss, avoiding burning loss, and uniform heating temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

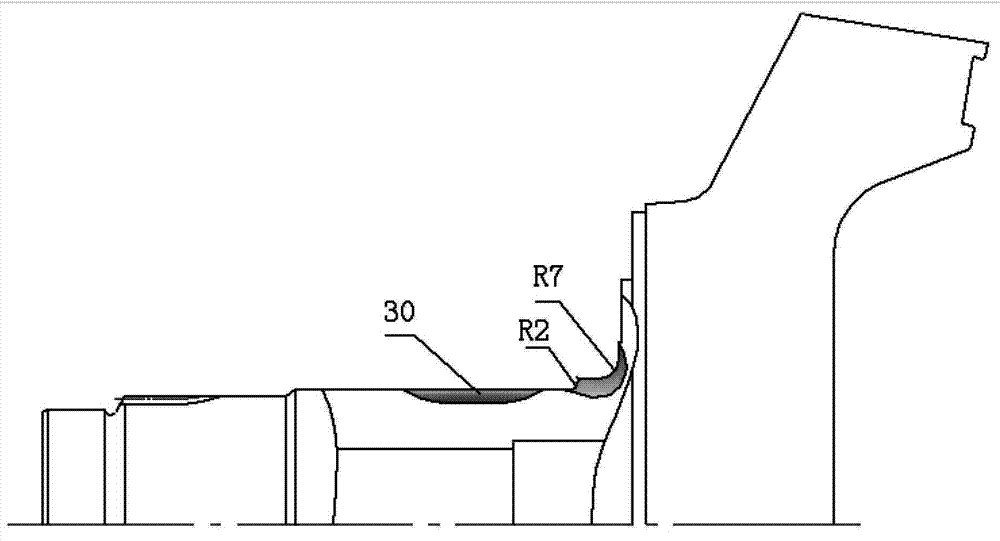

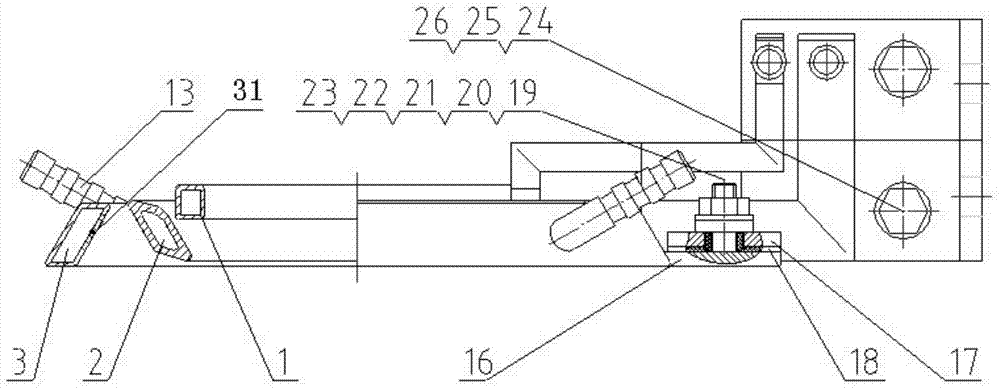

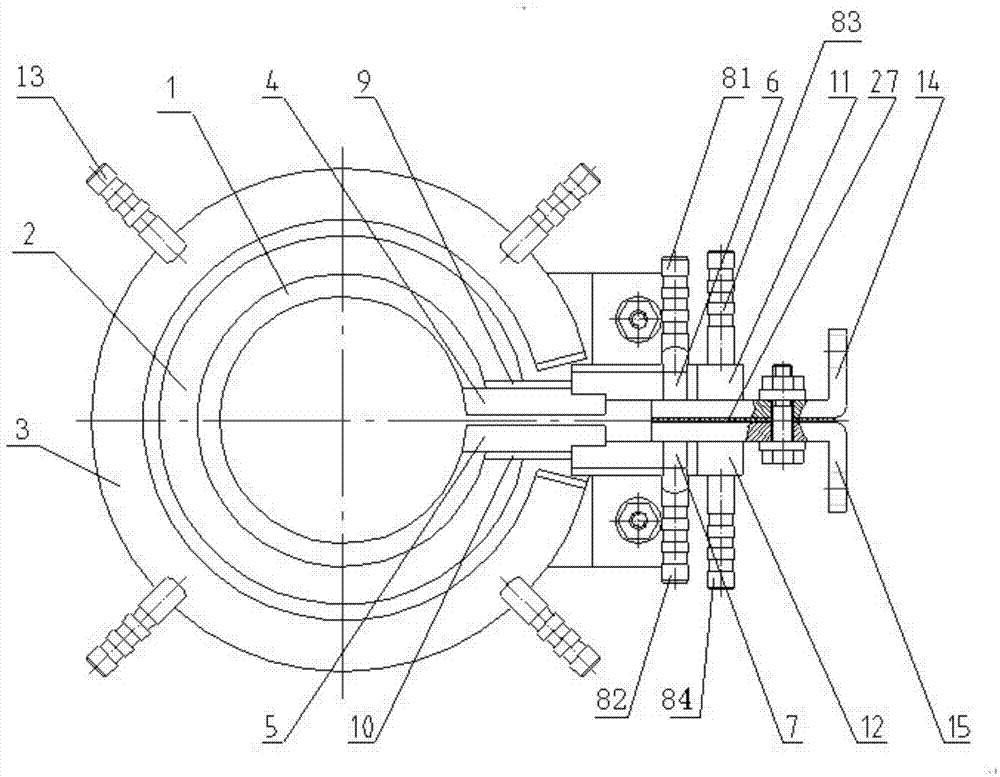

[0036] Step 1: place the journal part 30 of the part to be processed upward on the fixture of the lower center of the machine tool, tighten the upper center; press the start button to make the part to be processed start to rotate;

[0037] Step 2: After the part rotates for 2 seconds, the quenching sensor quickly moves from the initial position to the first stationary heating position at 3000mm / min. At this time, the first annular effective heating ring 1 corresponds to the second rounded corner R2 of the part. The acute-angled portion of the second annular effective heating ring 2 corresponds to the first rounded corner R7, and the first rounded corner R7 and the second rounded corner R7 of the steering knuckle are simultaneously treated by using the first annular effective heating ring 1 and the second annular effective heating ring 2 The second rounded corner R2 and part of the journal are preheated. After heating for 10 seconds, the ring water spray ring 3 starts to spray w...

Embodiment 2

[0043] Step 1: place the journal part 30 of the part to be processed upward on the fixture of the lower center of the machine tool, tighten the upper center; press the start button to make the part to be processed start to rotate;

[0044] Step 2: After the part rotates for 2 seconds, the quenching sensor quickly moves from the initial position to the first stationary heating position at 3000mm / min. At this time, the first annular effective heating ring 1 corresponds to the second rounded corner R2 of the part. The acute-angled portion of the second annular effective heating ring 2 corresponds to the first rounded corner R7, and the first rounded corner R7 and the second rounded corner R7 of the steering knuckle are simultaneously treated by using the first annular effective heating ring 1 and the second annular effective heating ring 2 The second fillet R2 and part of the journal are heated, and after 12 seconds of heating, the ring water spray ring 3 starts to spray water;

...

Embodiment 3

[0050] Step 1: place the journal part 30 of the part to be processed upward on the fixture of the lower center of the machine tool, tighten the upper center; press the start button to make the part to be processed start to rotate;

[0051] Step 2: After the part rotates for 2 seconds, the quenching sensor quickly moves from the initial position to the first stationary heating position at 3000mm / min. At this time, the first annular effective heating ring 1 corresponds to the second rounded corner R2 of the part. The acute-angled portion of the second annular effective heating ring 2 corresponds to the first rounded corner R7, and the first rounded corner R7 and the second rounded corner R7 of the steering knuckle are simultaneously treated by using the first annular effective heating ring 1 and the second annular effective heating ring 2 The second fillet R2 and part of the journal are heated, and after 11 seconds of heating, the ring water spray ring 3 starts to spray water;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com