Flexible assembly system for aircraft panel

An aircraft wall panel and flexible assembly technology, applied in aircraft assembly, aircraft parts, assembly machines, etc., can solve problems such as poor quality stability, low hole-making efficiency, and large gaps, and achieve flexibility, cost savings, and reduced The effect of the assembly cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

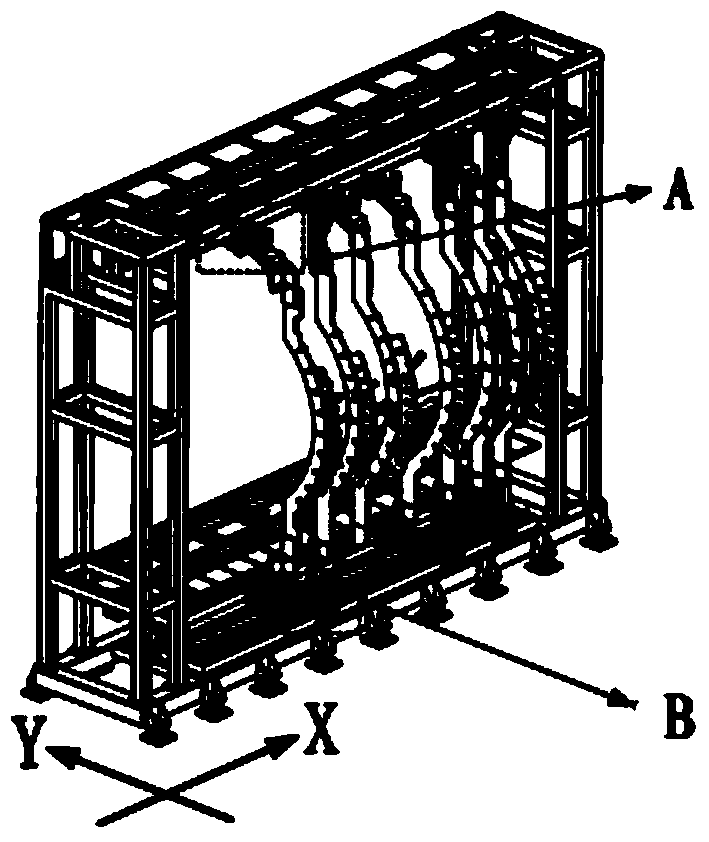

[0059] The flexible assembly system for aircraft panels of the present invention will be described in detail below in conjunction with the accompanying drawings.

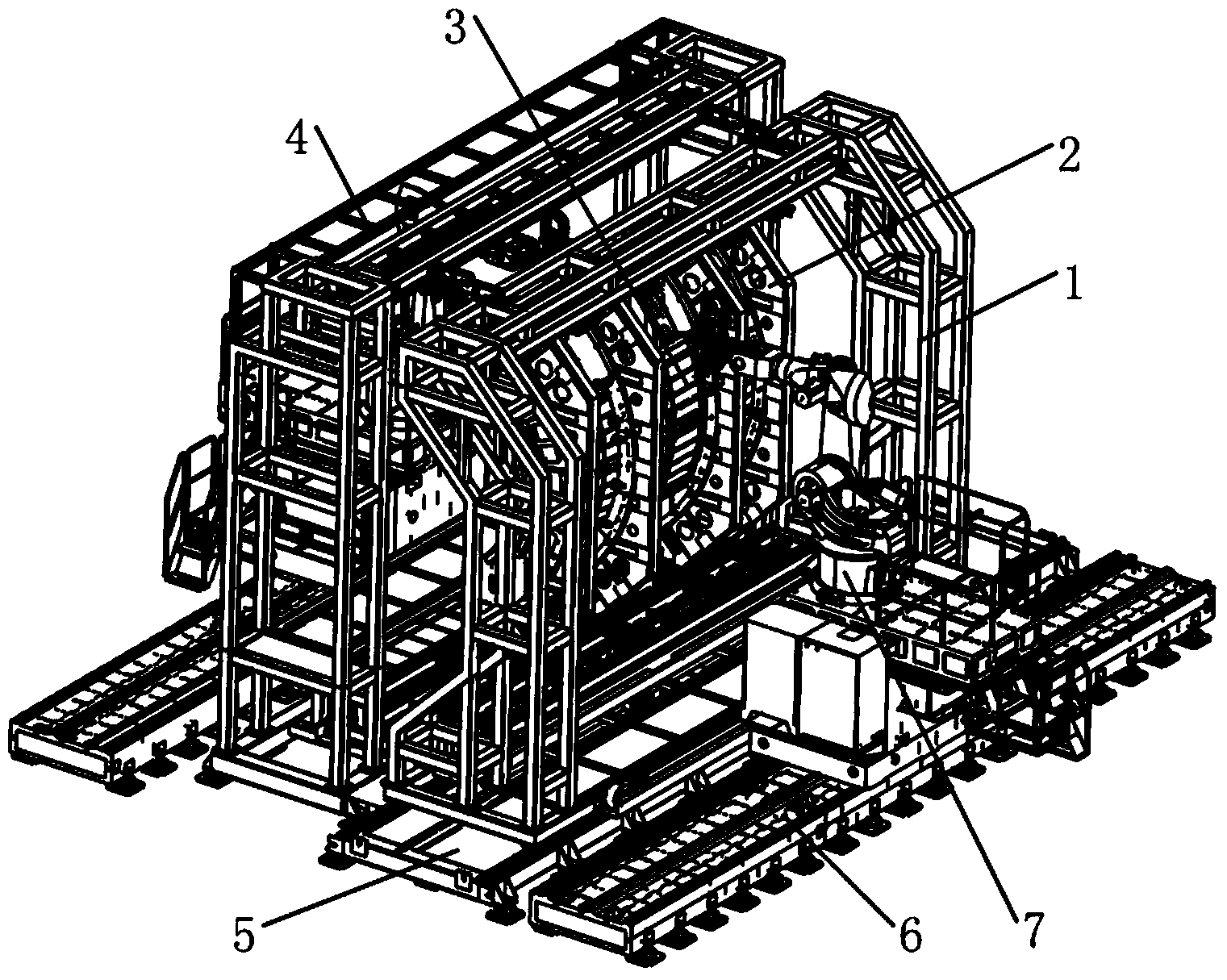

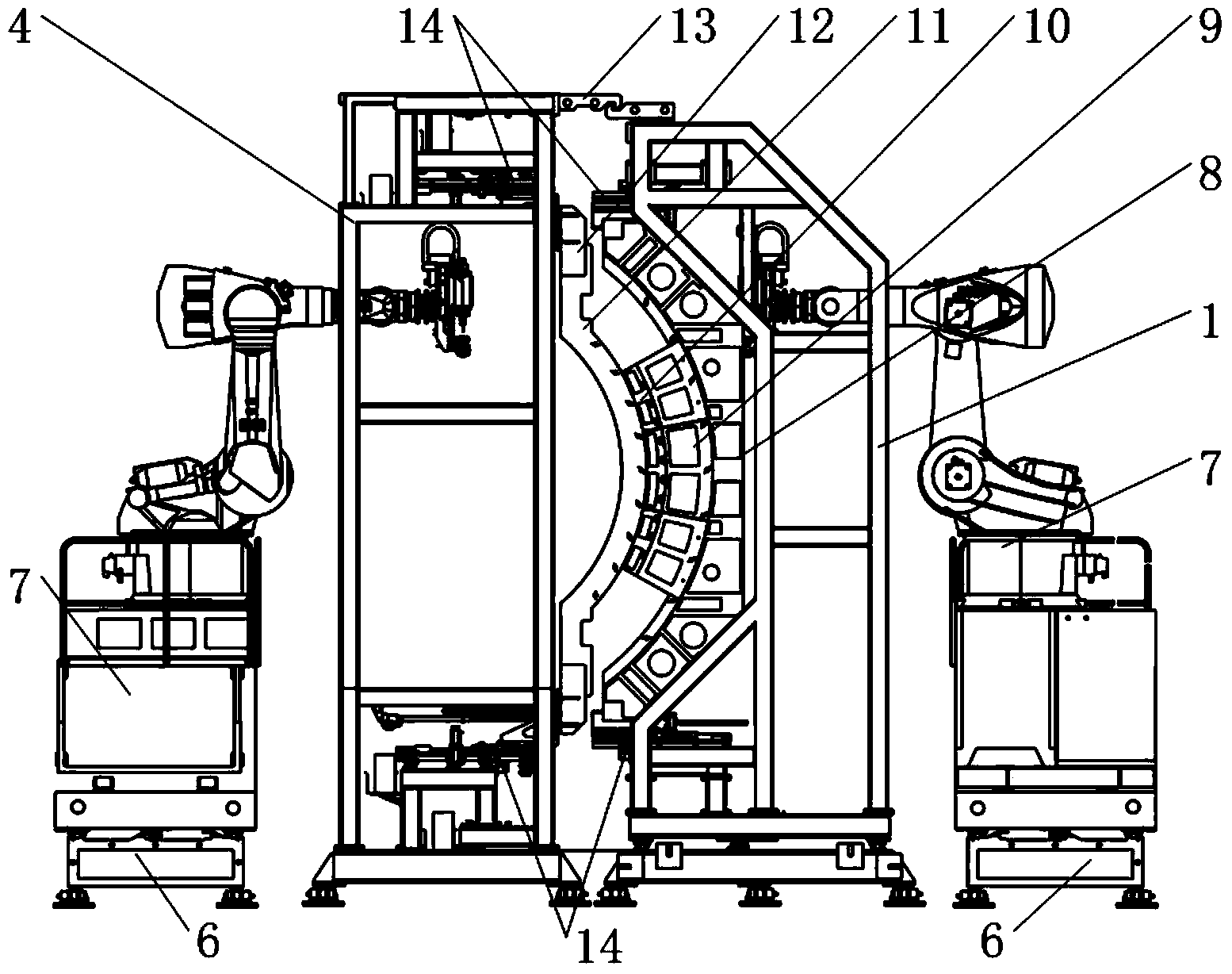

[0060] Such as figure 1 , 2 As shown, a flexible assembly system for aircraft panels includes:

[0061] Fixed base frame 4, fixedly installed on the ground;

[0062] The movable base frame 1 cooperates with the fixed base frame;

[0063] The pedestal base 5 is provided with a linear guide rail arranged along the X-axis direction, and the movable pedestal is slidably matched with the linear guide rail;

[0064] A number of flexible clamping board assemblies 2 are arranged on the fixed base frame and the movable base frame for clamping the aircraft wall panel 3;

[0065] Several transmission positioning units 14 are arranged on the fixed base frame and the movable base frame, and are used to adjust the position of the flexible clamp assembly;

[0066] The locator buckle 13 is arranged between the movable base fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com