Biopharmaceutical process apparatuses assembled into a column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

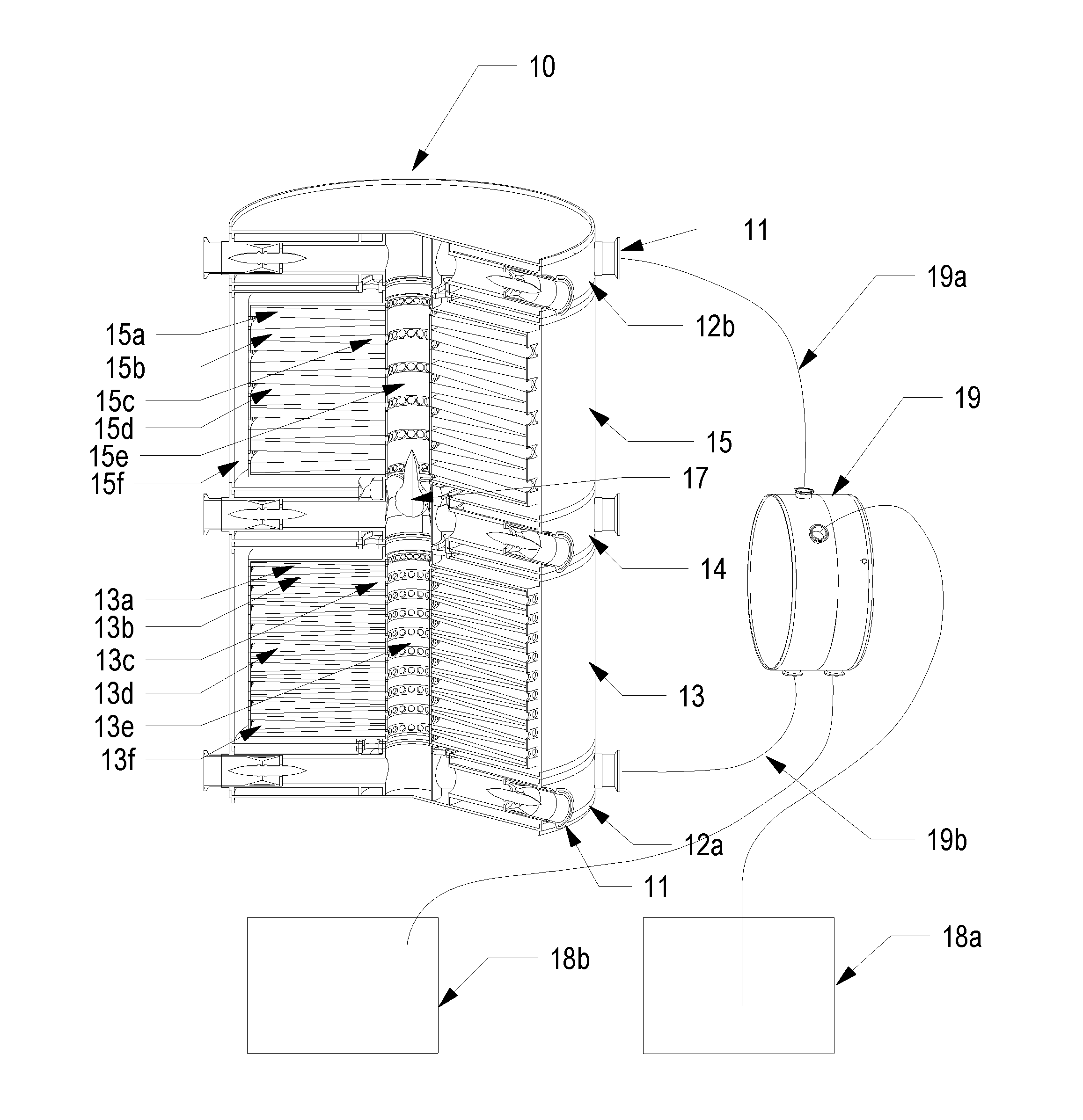

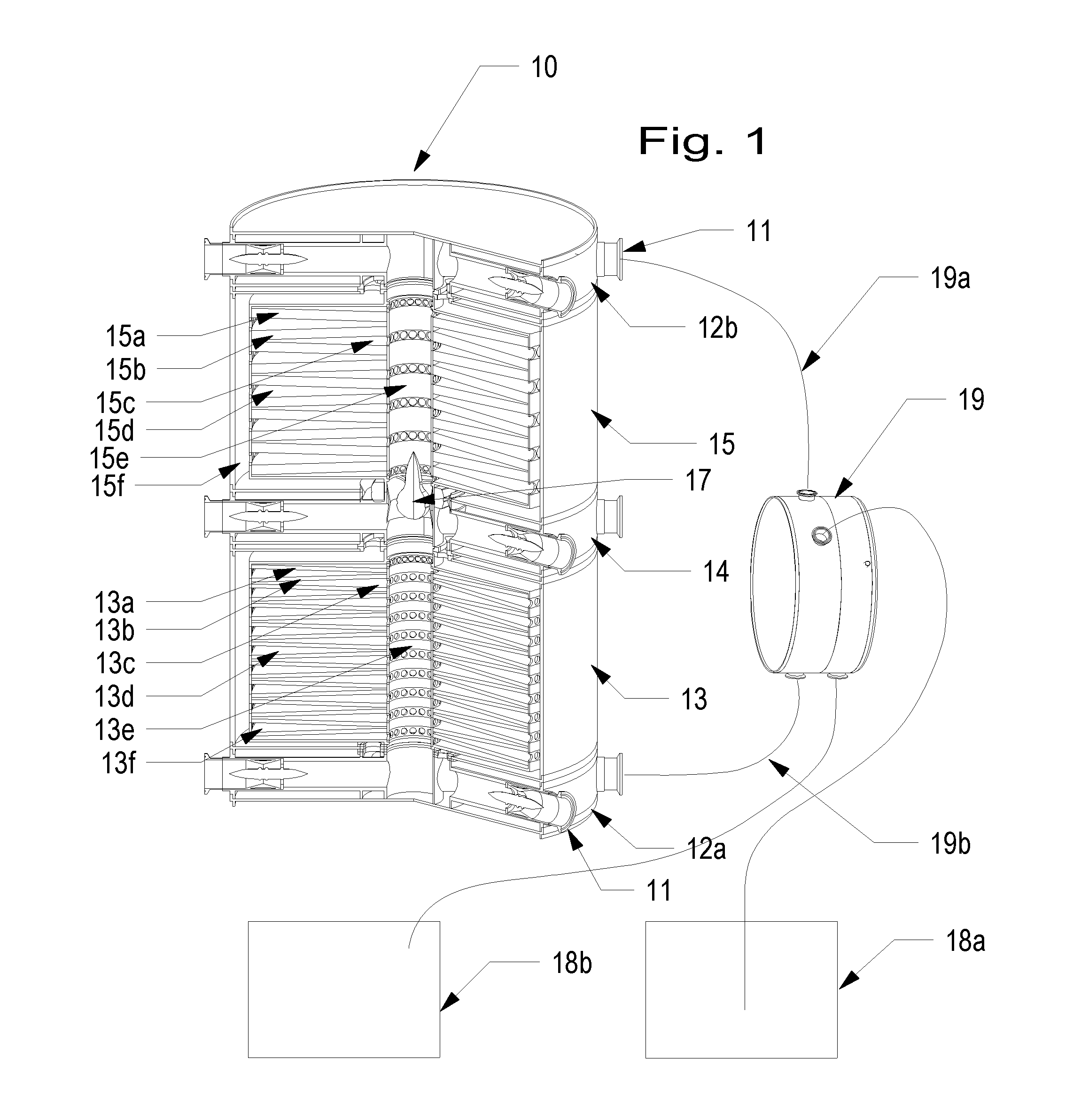

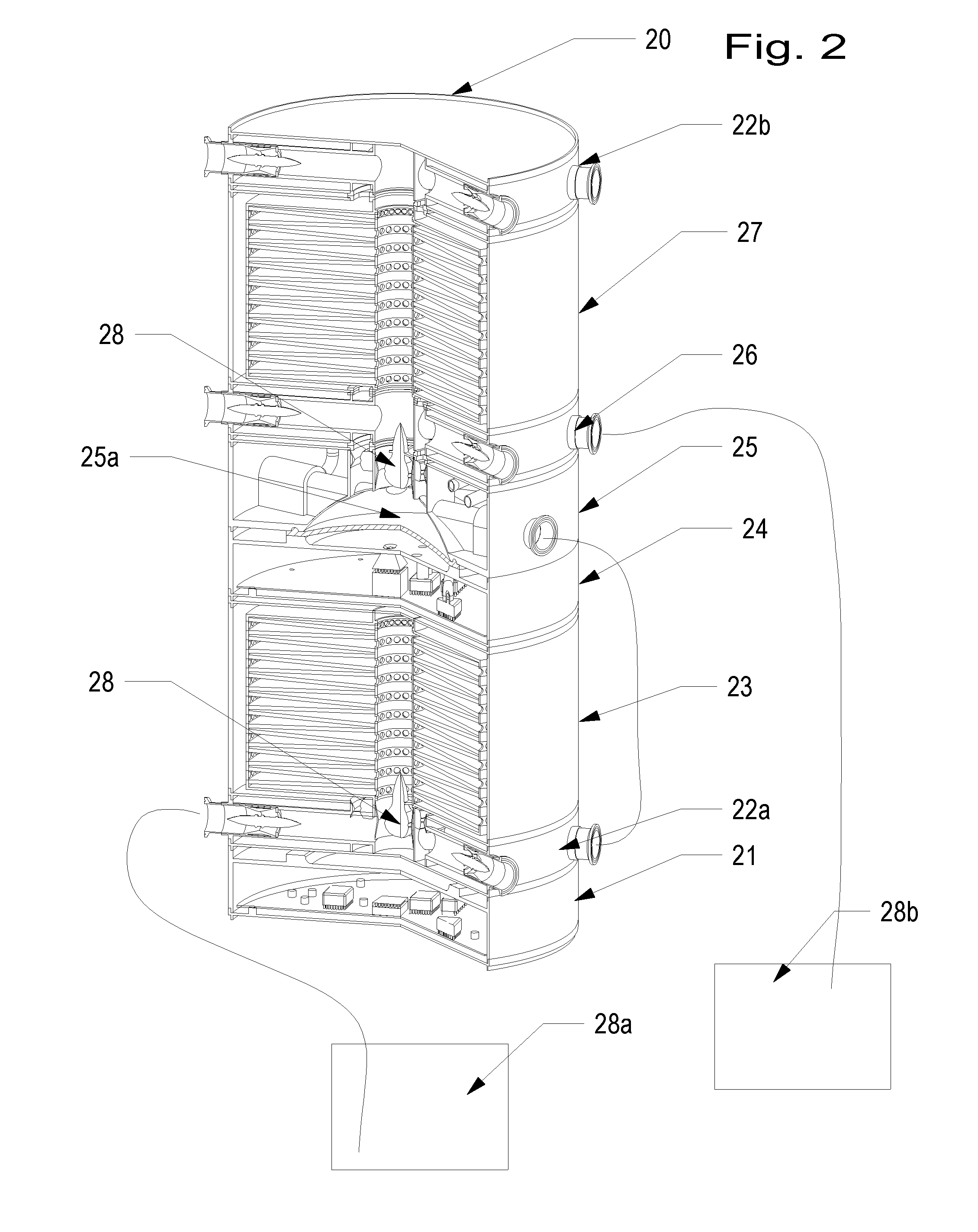

[0116]In one aspect the present invention relates to a bioreactor apparatus having a top capsule and a bottom capsule, the apparatus comprising a cultivation capsule having a production device for producing a biologic product, and a second upstream capsule, wherein said capsules are stacked and locked in a column, with the proviso that the top capsule and bottom capsule are not pump capsules at the same time.

[0117]Thus, the top capsule may be a cultivation capsule and the bottom capsule may be the second upstream capsule or may be the third or so forth capsule. Alternatively, the cultivation capsule may be located between the top and bottom capsules and may consist of one or more cultivation capsules.

[0118]The bioreactor apparatus is preferably for single use, or is pre-sterilized or both. The bioreactor may be any suitable bioreactor, such as a bioreactor selected from a batch, fed-batch, or continuous mode, e.g. continuous perfusion.

[0119]The bioreactor may be connected to a purif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com