A magnetorheological flexible clamp for thin-walled parts with arbitrary shape

A technology of flexible fixtures and thin-walled parts, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of affecting the processing accuracy of the workpiece, affecting the performance, and high cost, so as to achieve flexible operation, ensure stability, and suitable size strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

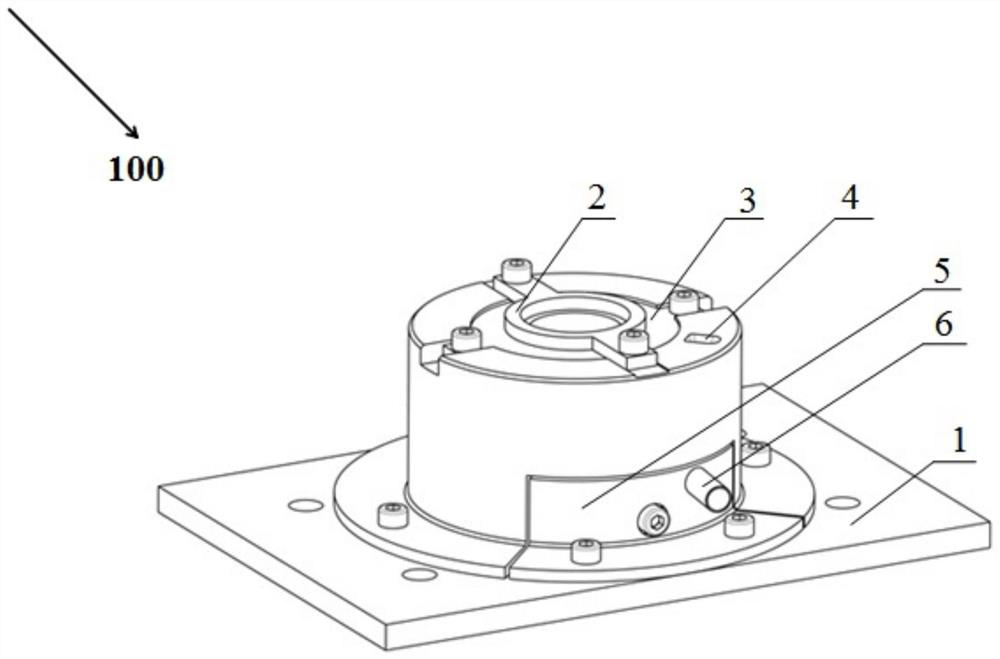

[0032] like figure 1 As shown, a magnetorheological flexible fixture 100 for thin-walled parts with arbitrary shapes in this embodiment is used for processing thin-walled parts 9 with arbitrary shapes, including: a base 1, a mechanical pressing part 2, a sealing cover 3, a liquid inlet Hole 4, mechanical clamping part 5 and drain pipe 6.

[0033] In this embodiment, the thin-walled parts 9 are thin-walled shells, frame-like parts, and the like.

[0034] The base 1 is placed on the workbench.

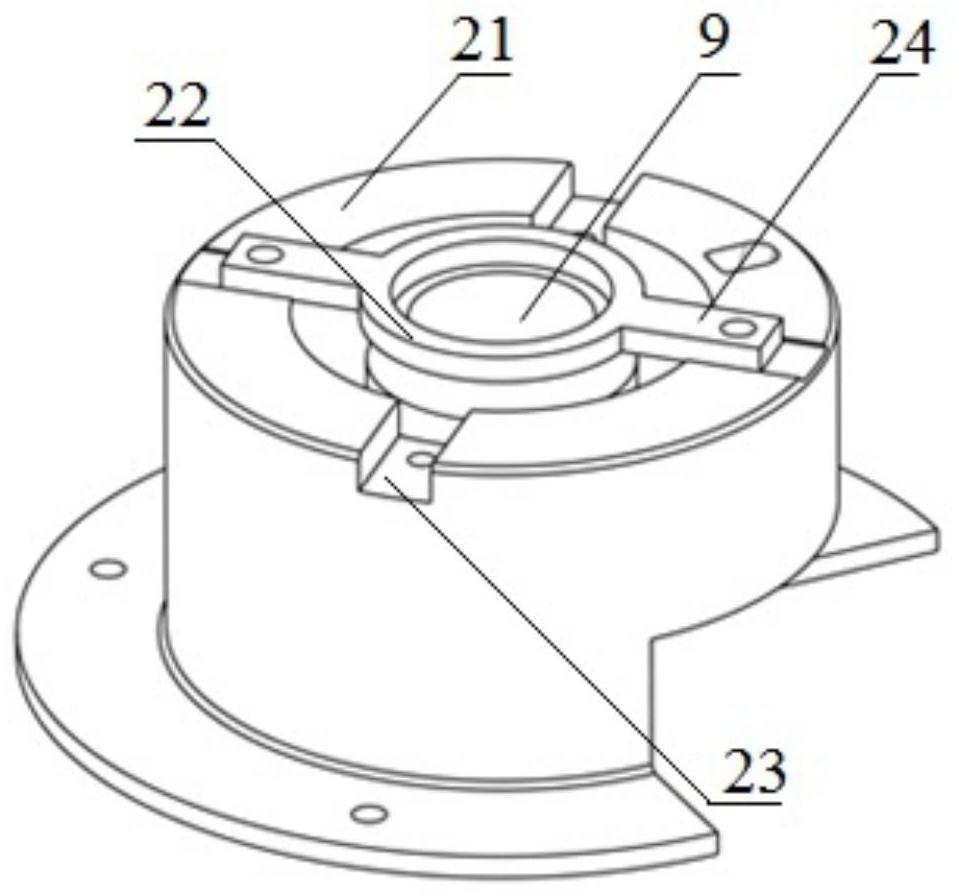

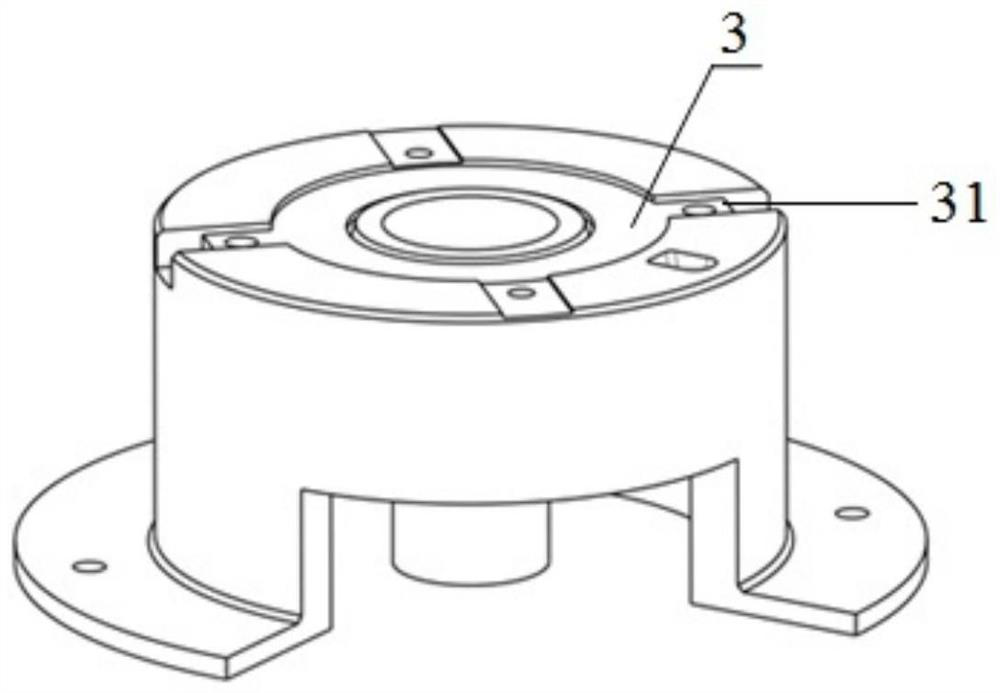

[0035] like figure 1 and figure 2 As shown, the mechanical pressing part 2 is used for pressing the thin-walled parts 9, including a support with a thin-walled part 9 placed inside and fixed on the base 1 by nuts, four through grooves 23 evenly distributed at the top and an annular gap at the bottom The sleeve 21 and the annular pressure block 22 disposed on the top of the support sleeve 21 , and both ends of the annular pressure block 22 are clamped into the two through grooves 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com