Adjustable strong inductive coupling structure of cavity filter

A cavity filter and inductive coupling technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve problems such as difficulty in improving the coupling coefficient, and achieve the effects of simple processing, high coupling strength, and adjustable production process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

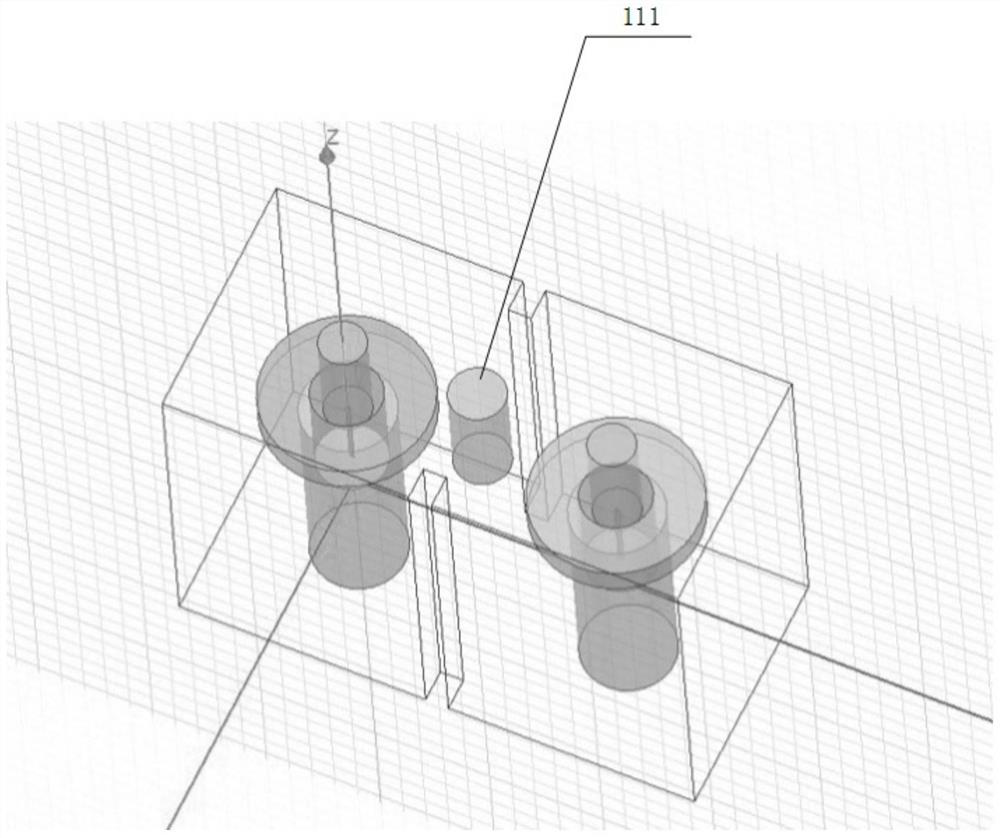

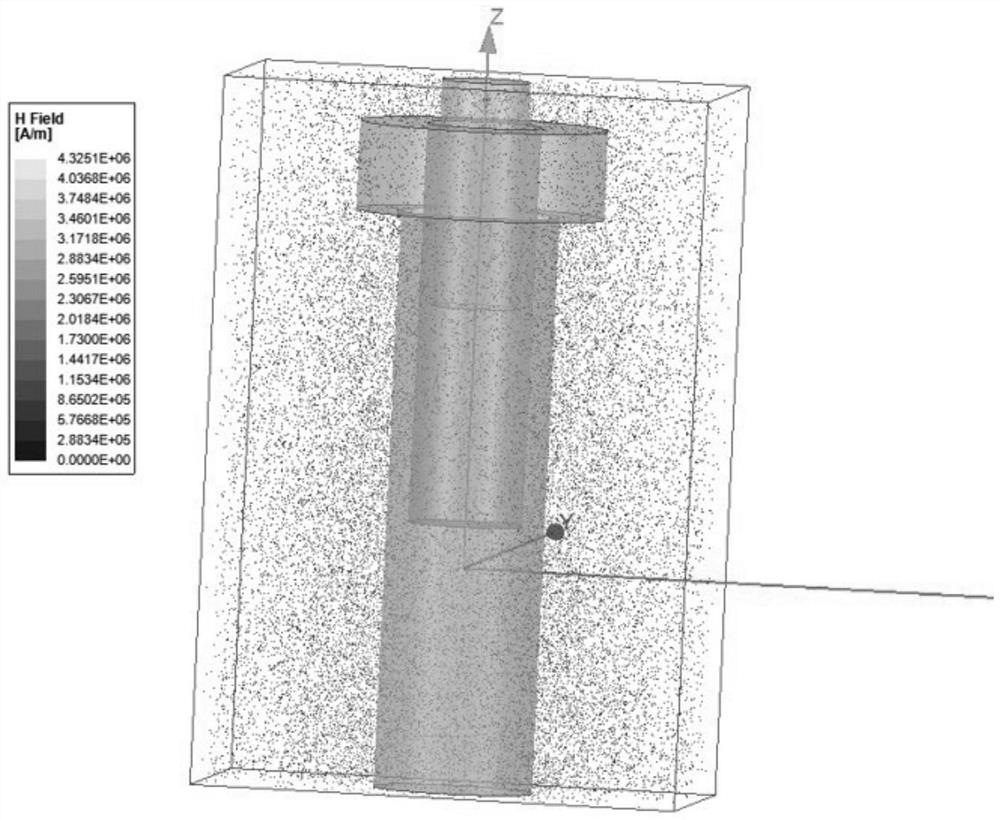

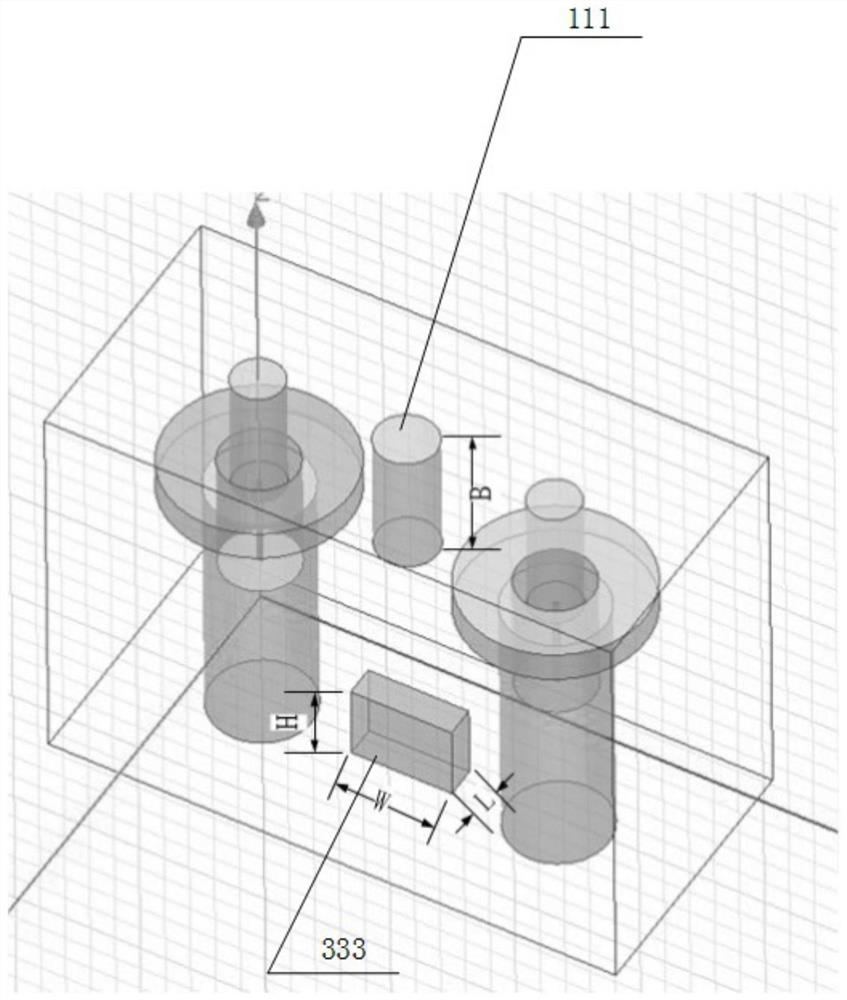

[0029]Such asFigure 1 ~ 4As shown, those skilled in the art can carry out the modulated sensing coupling structure of a cavity filter as a cavity filter, and there are two resonant cavities and a cylindrical metal, and a rectangle is provided between the two resonant cavities. Cylindrical 333; the rectangular column 333 is coupled to the cylindrical metal, by changing the long-width height of the rectangular cylinder, can sufficiently adjust the coupling strength from the design, which can meet the narrowband demand and achieve broadband strong coupling. By cooperating with a cylindrical metal coupling method (tuning screw), it is satisfied with the adjustability of the production; and the rectangular column 333 is provided between the two resonant cavity bottoms, and the tuning screw 111 is provided; the length of the rectangular column is changed. L, wide, high, and tuning screw length B, square post coupling mating cylindrical coupling; a rectangular cylinder is increased between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com