Patents

Literature

64results about How to "Play the role of clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

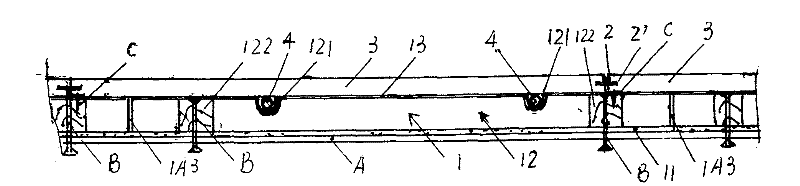

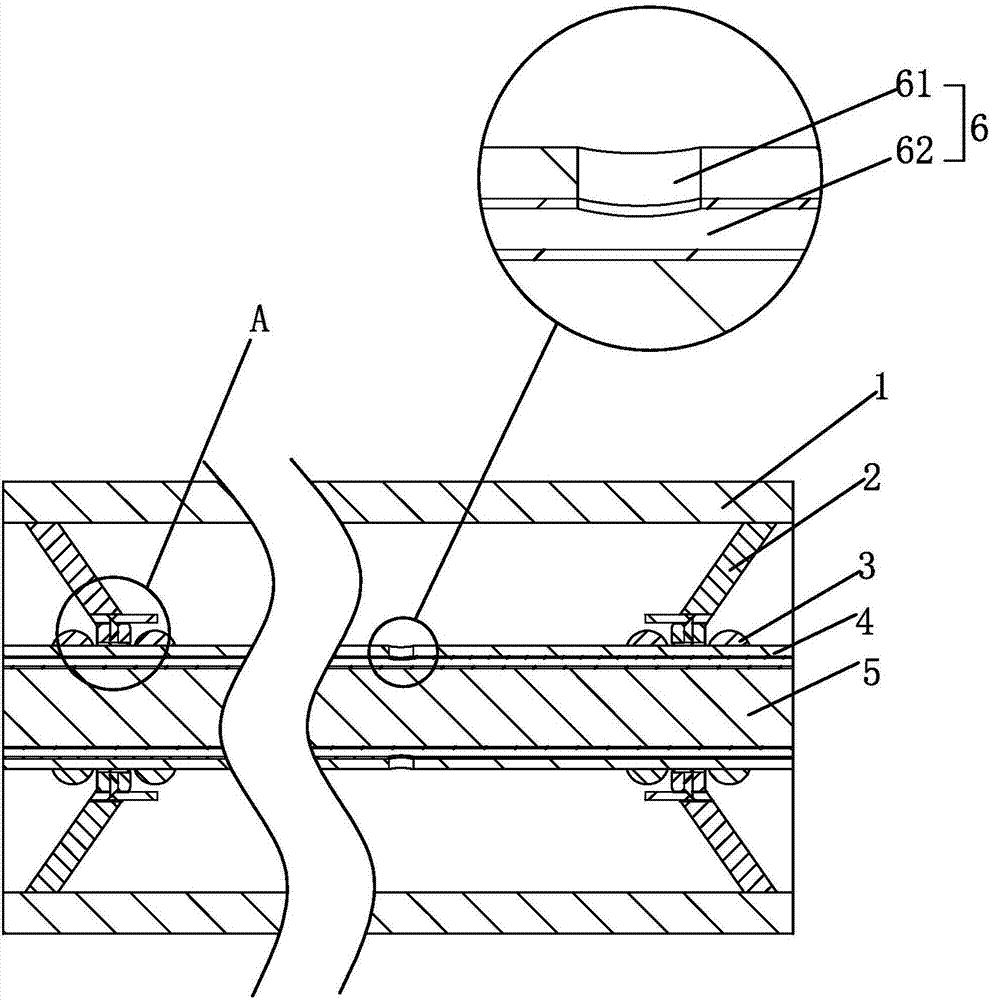

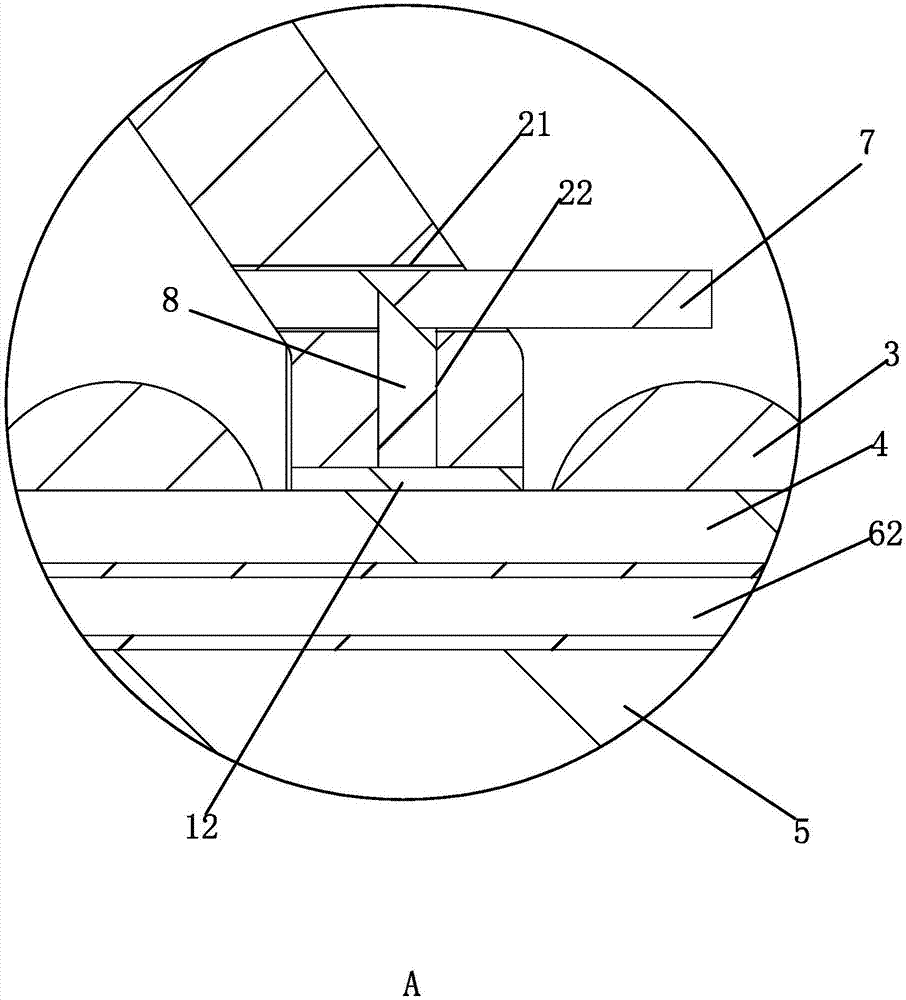

Novel multi-purpose fireproof composite heat-insulation plate

InactiveCN102304969APlay a role in strengthening supportMake up for the defect of low compressive strengthCovering/liningsSustainable buildingsCompound aSurface layer

The invention relates to a novel multi-purpose fireproof composite heat-insulation plate comprising a fireproof composite heat-insulation plate body, a fastener and a heat storage substrate plate or a surface-layer veneer plate, wherein the fireproof composite heat-insulation plate body sequentially is formed by sequentially compounding a protective layer, a composite heat-insulation plate or a heat-insulation plate and a fireproof antiflaming reflecting layer or a reflecting layer from bottom to top; an underfloor heating pipe groove is arranged at the upper end of the composite heat-insulation plate or the heat-insulation plate; and the heat storage substrate plate or the surface-layer veneer plate and a supporting base in the composite heat-insulation plate are anchored on the fireproof composite heat-insulation plate body and an underfloor heating pipeline by using the fastener and a bolt or using the bolt directly. The novel multi-purpose fireproof composite heat-insulation plate is suitable for dry-type or wet-method low-temperature radiation heating of floors of various structural forms including steel structures and the like and inner and outer walls and roof heat insulation, improves the fireproof property of the composite heat-insulation plate, ensures that the composite heat-insulation plate can meet the new fireproof requirement and ensures the fire safety of building heat-insulation materials, and has the advantages of simplicity and convenience for installation, lower cost, economy and practicability, broad application and better decoration effect.

Owner:冯刚克

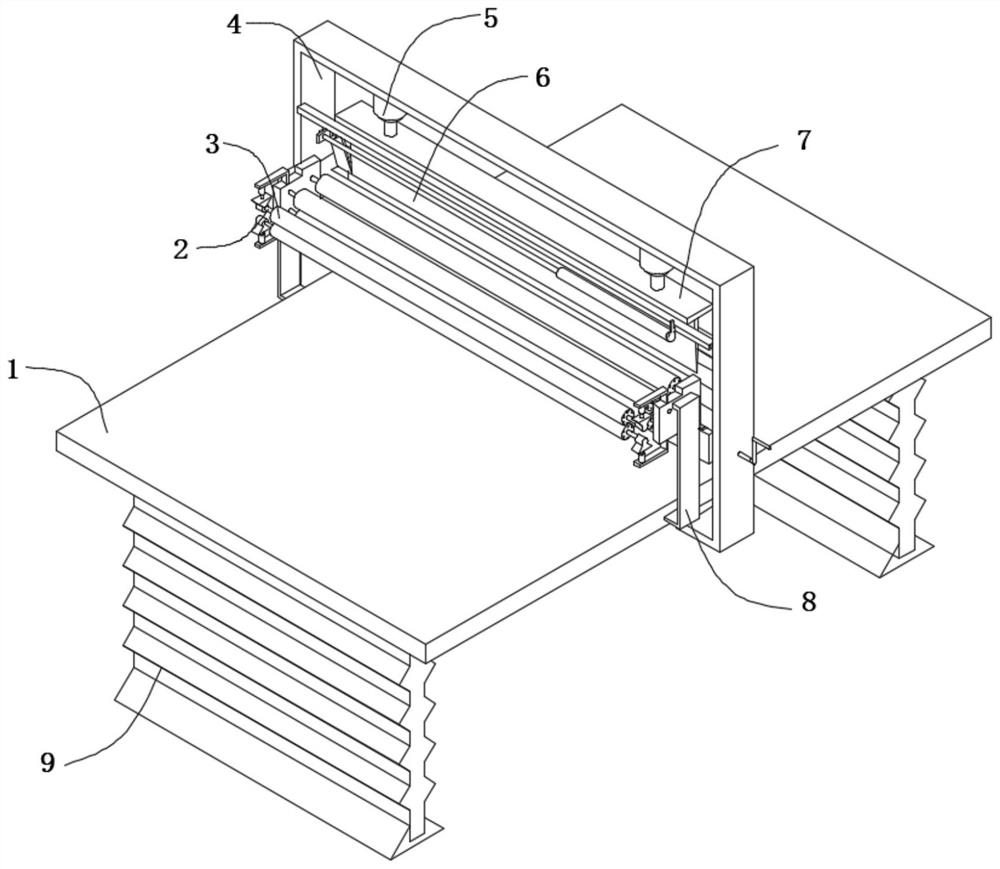

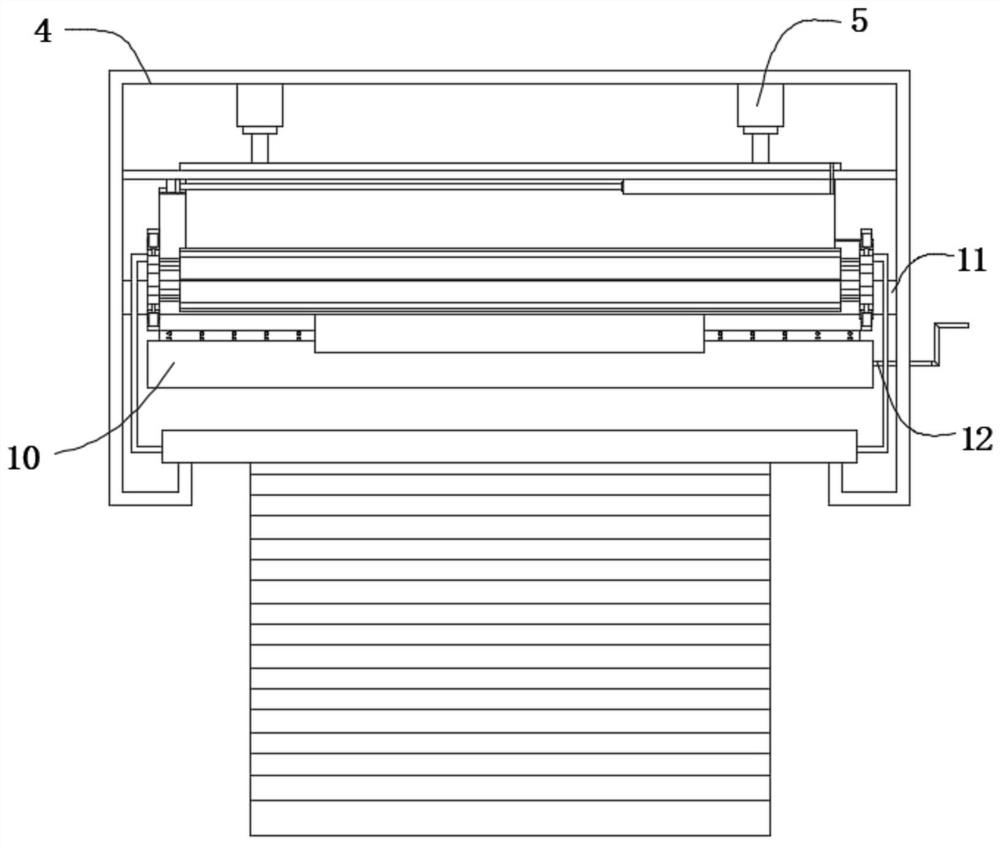

Laminating device for enhancing laminating precision of cover film

Owner:JIANGXI KAIQIANG IND CO LTD

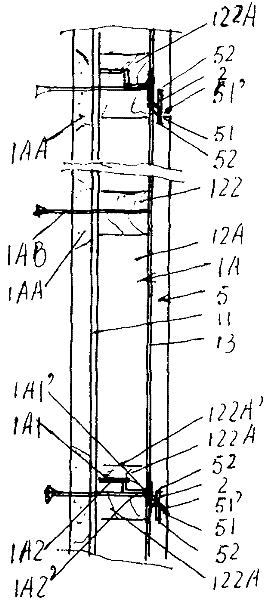

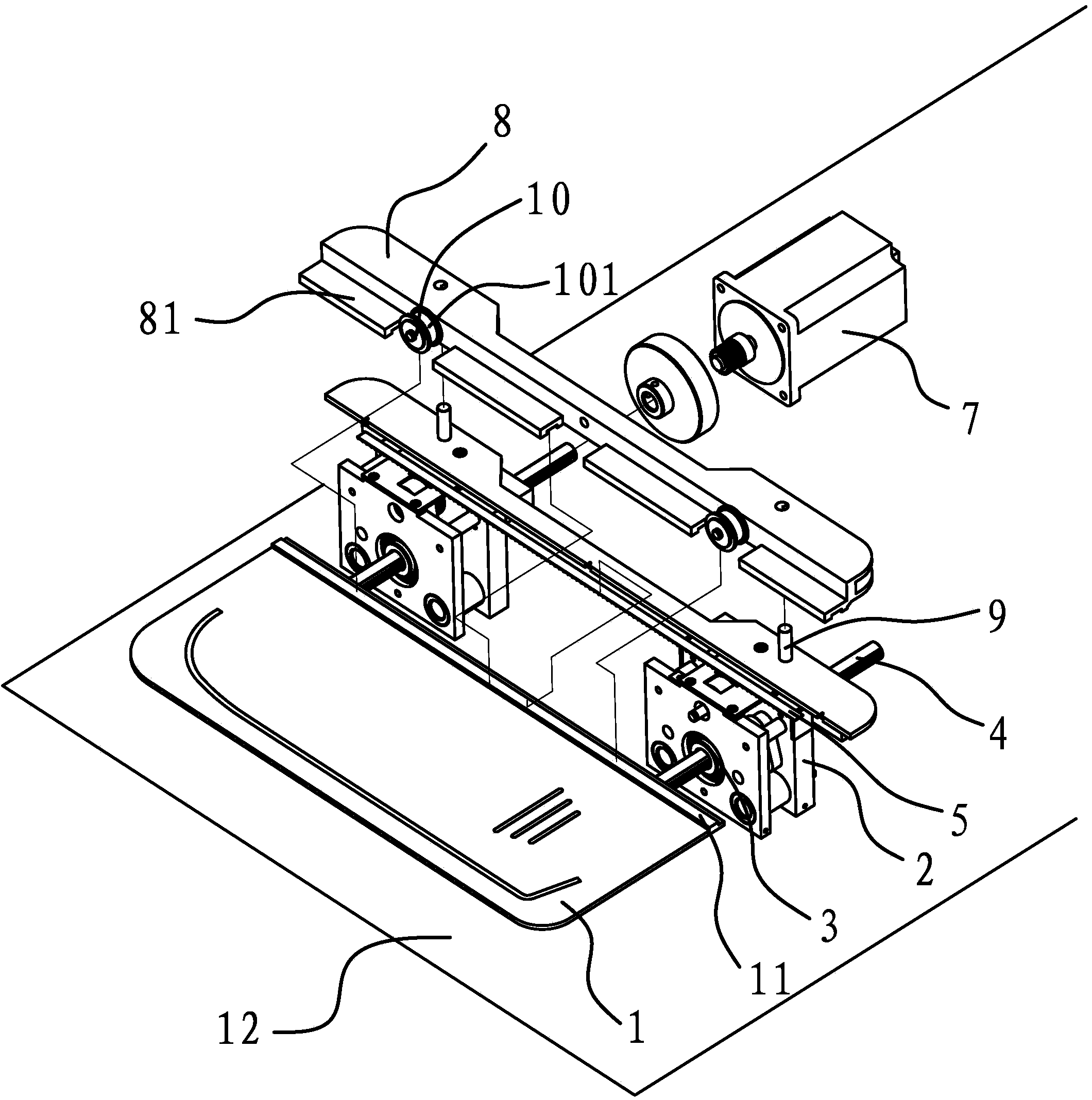

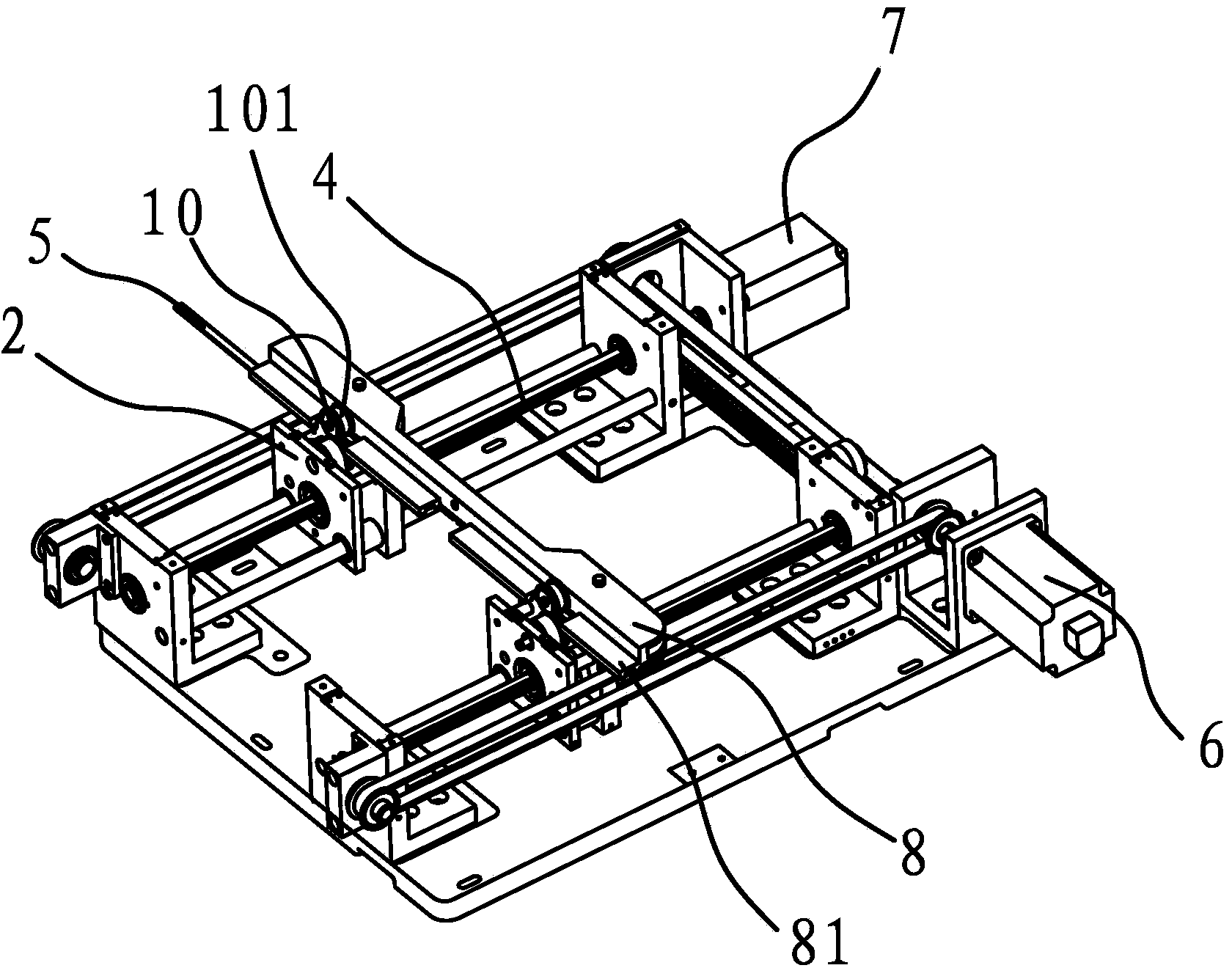

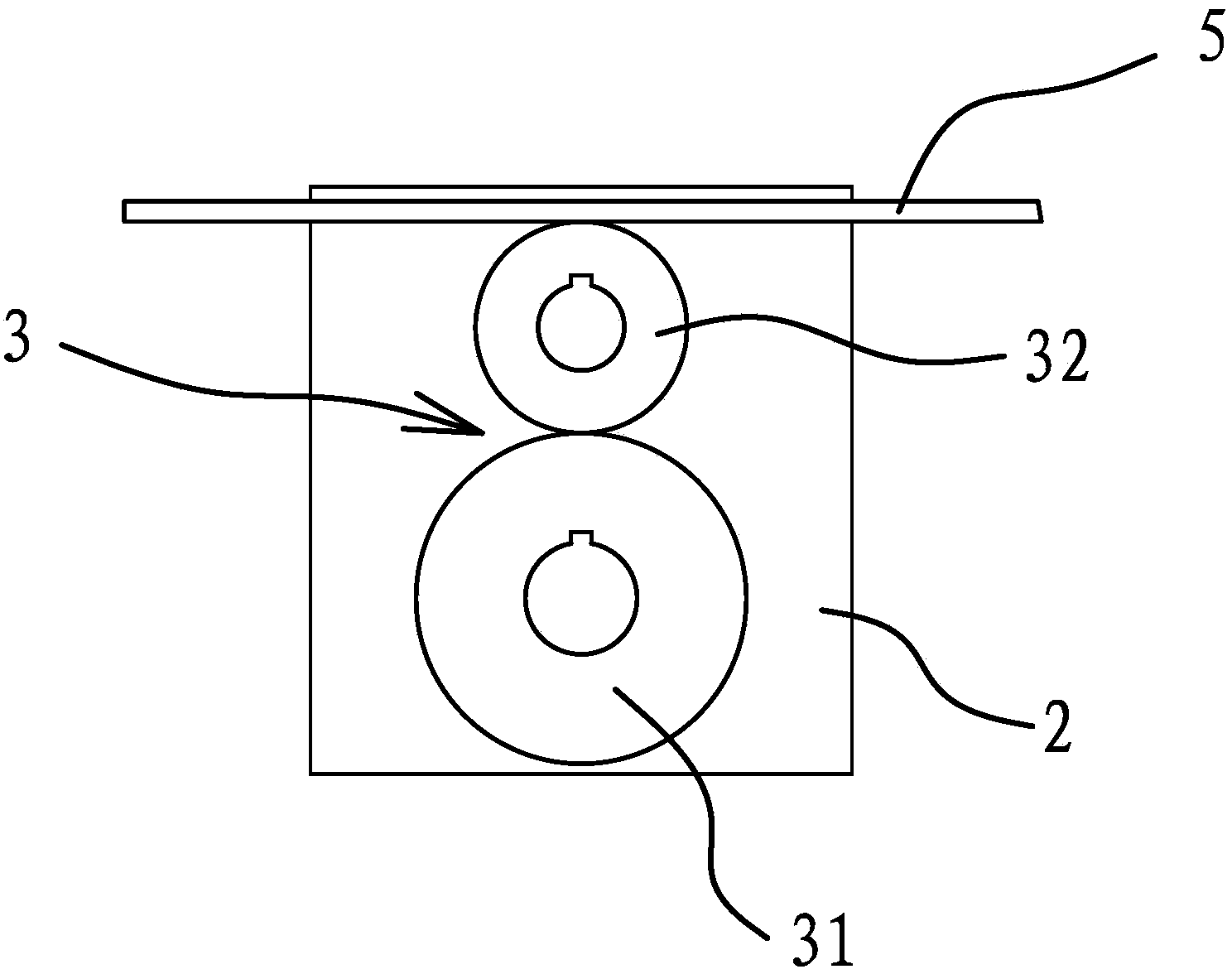

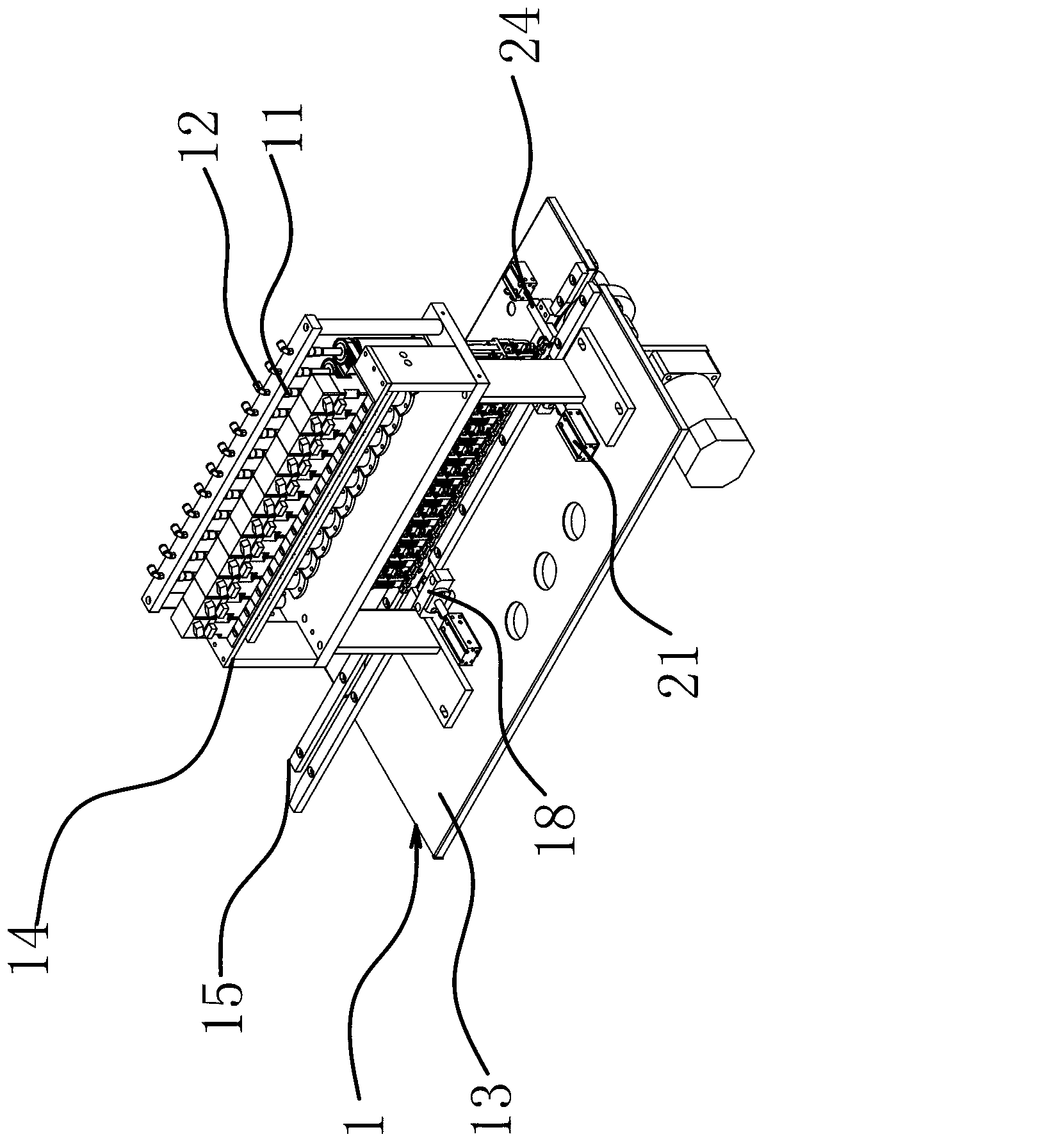

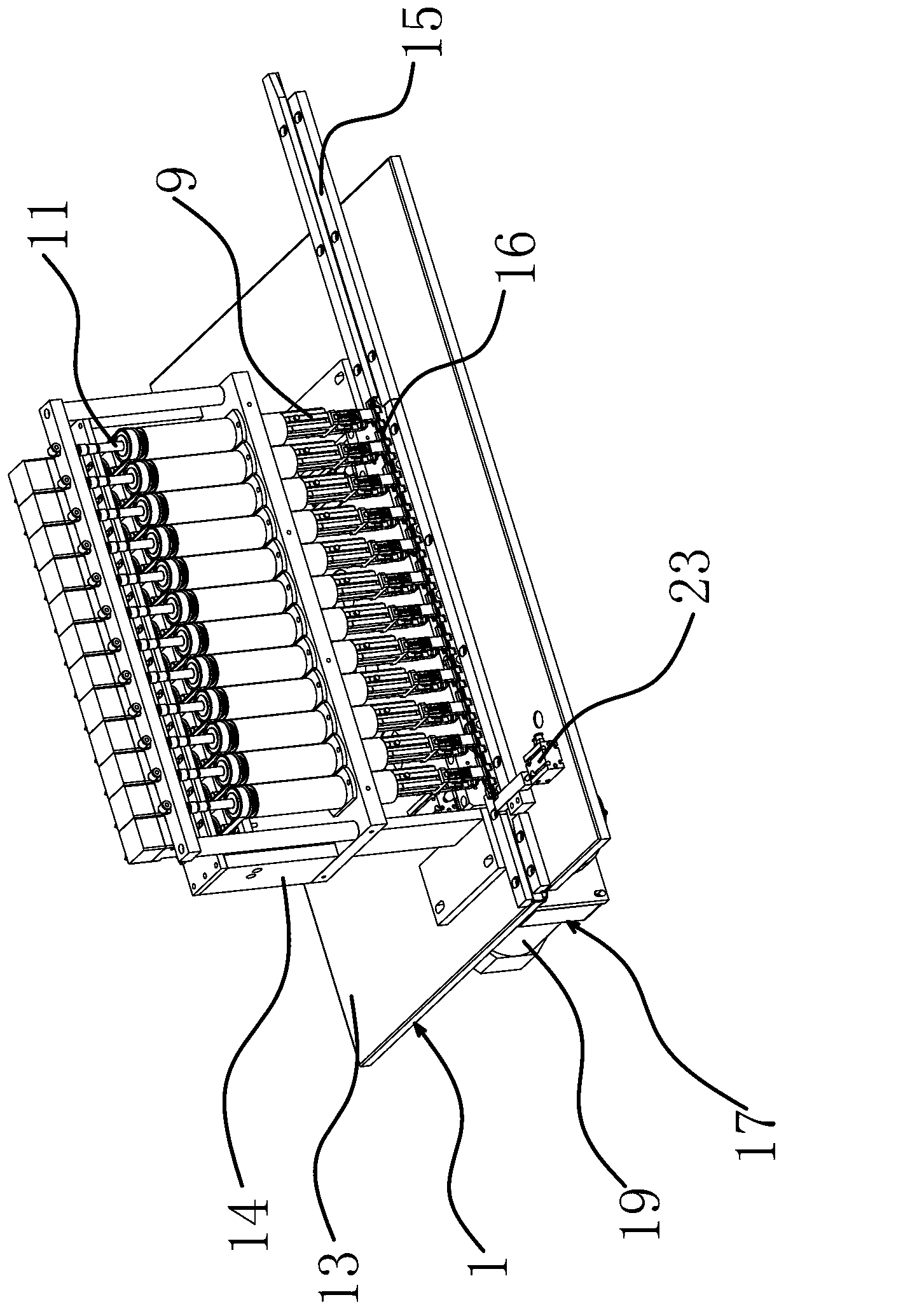

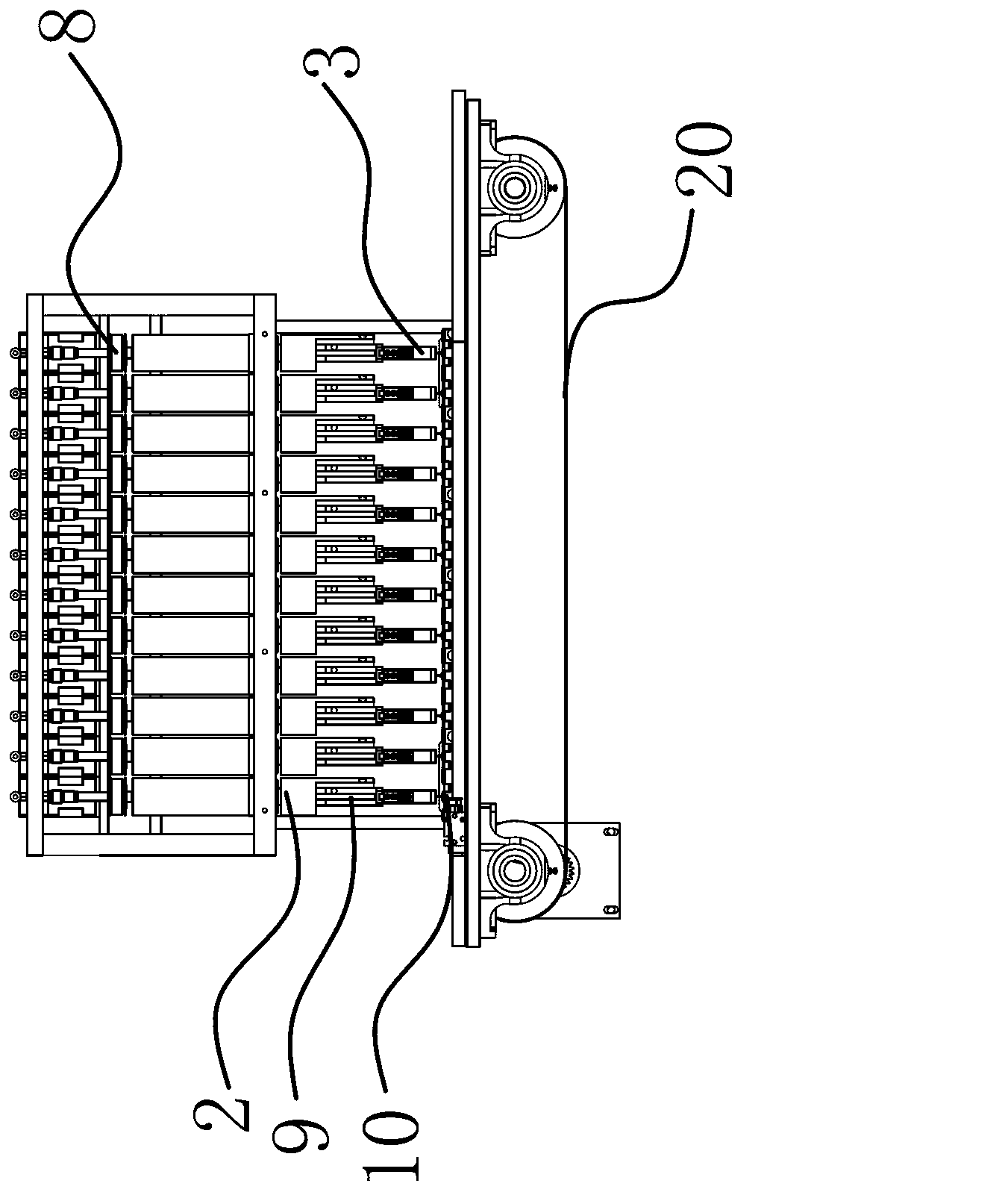

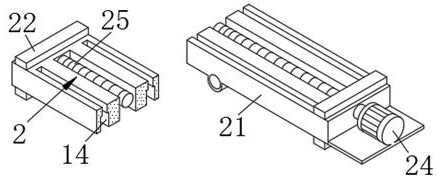

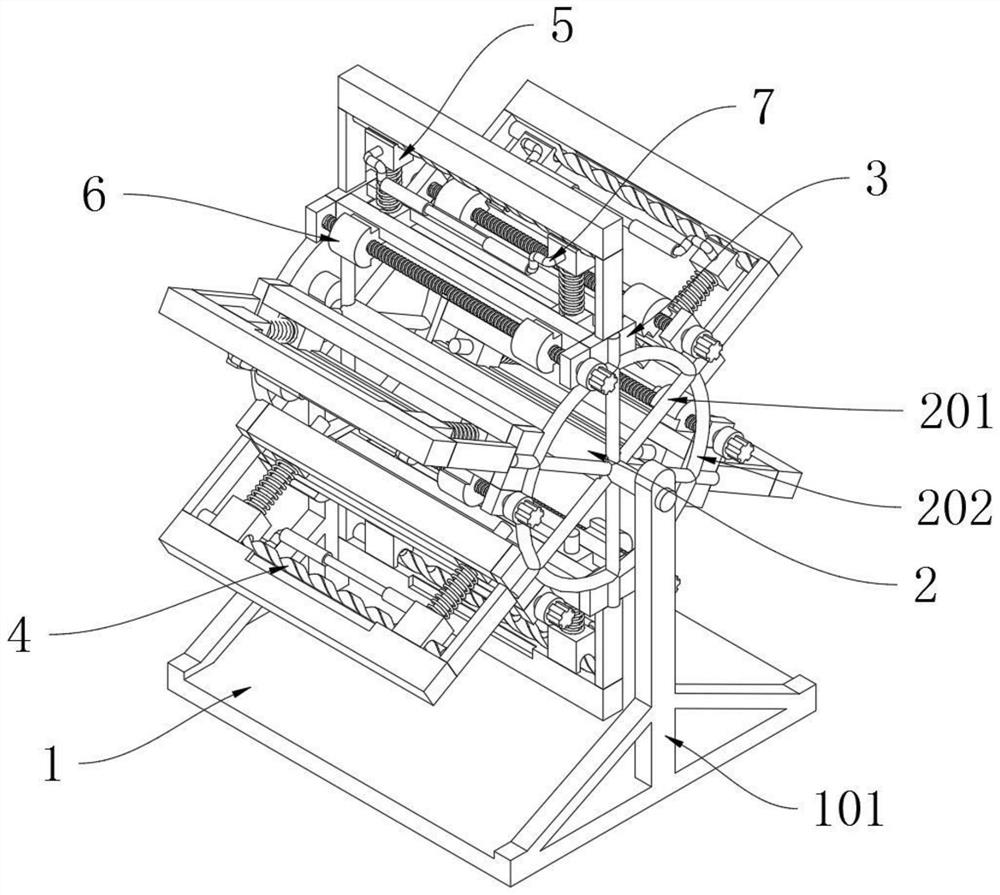

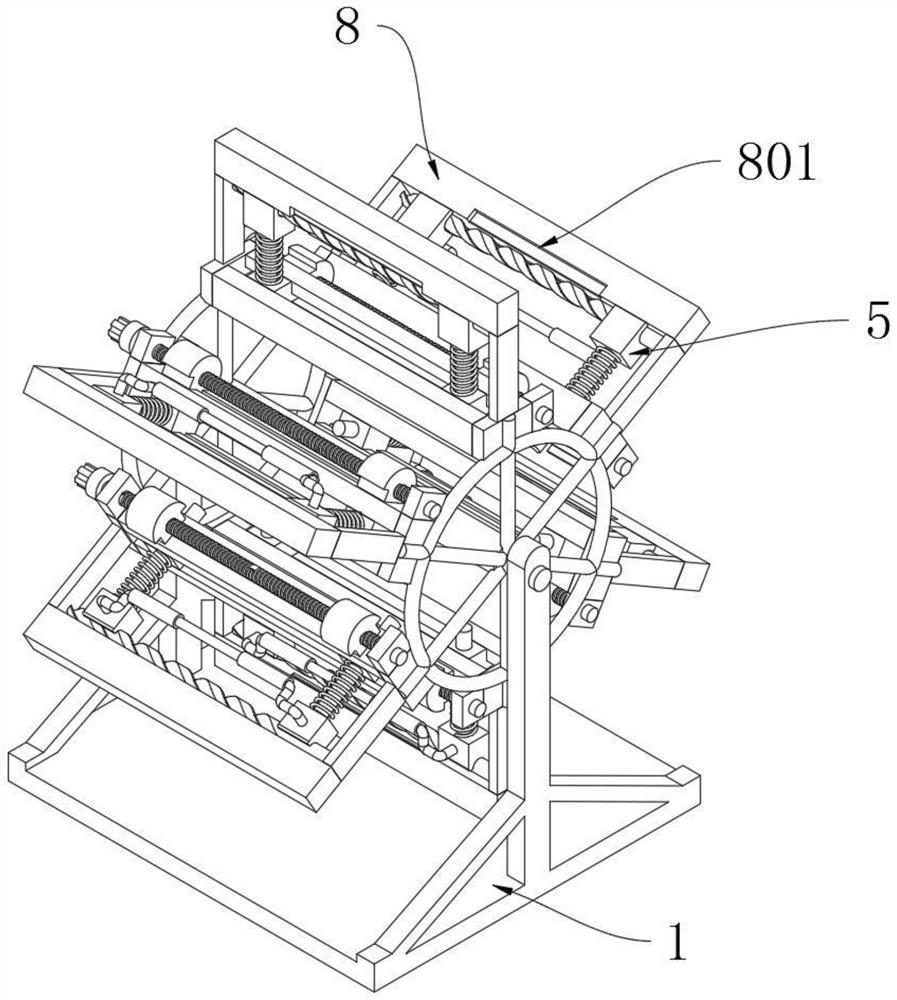

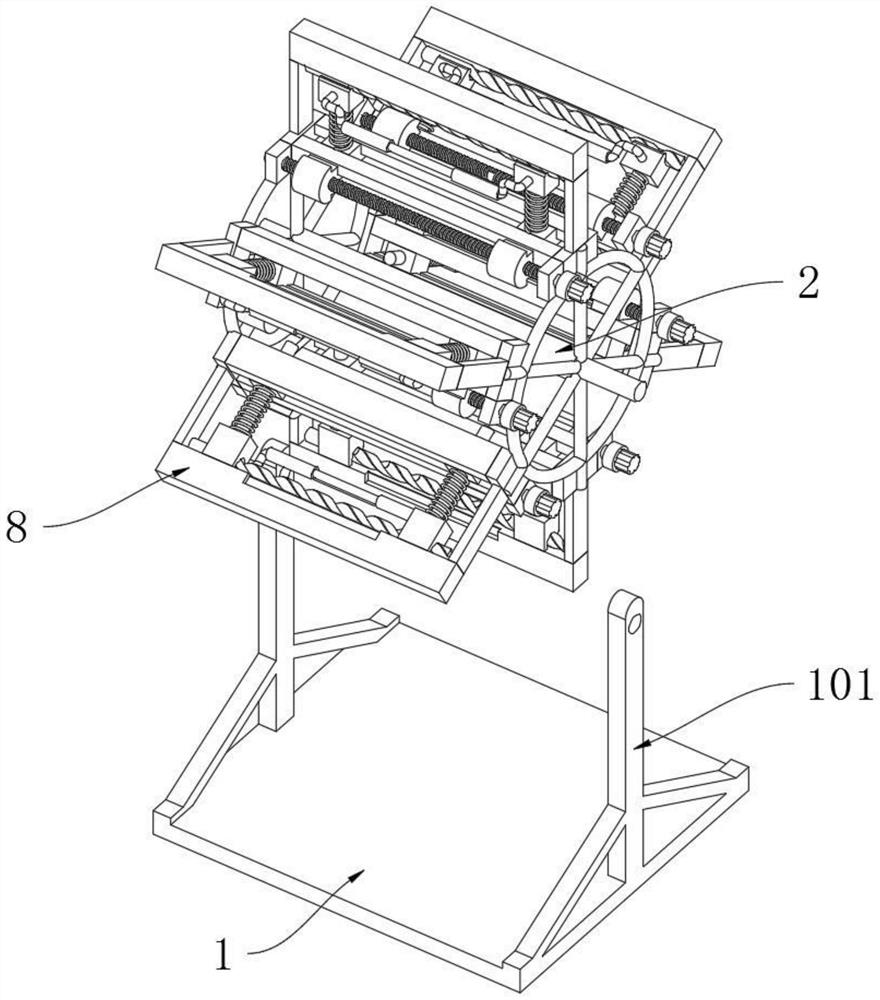

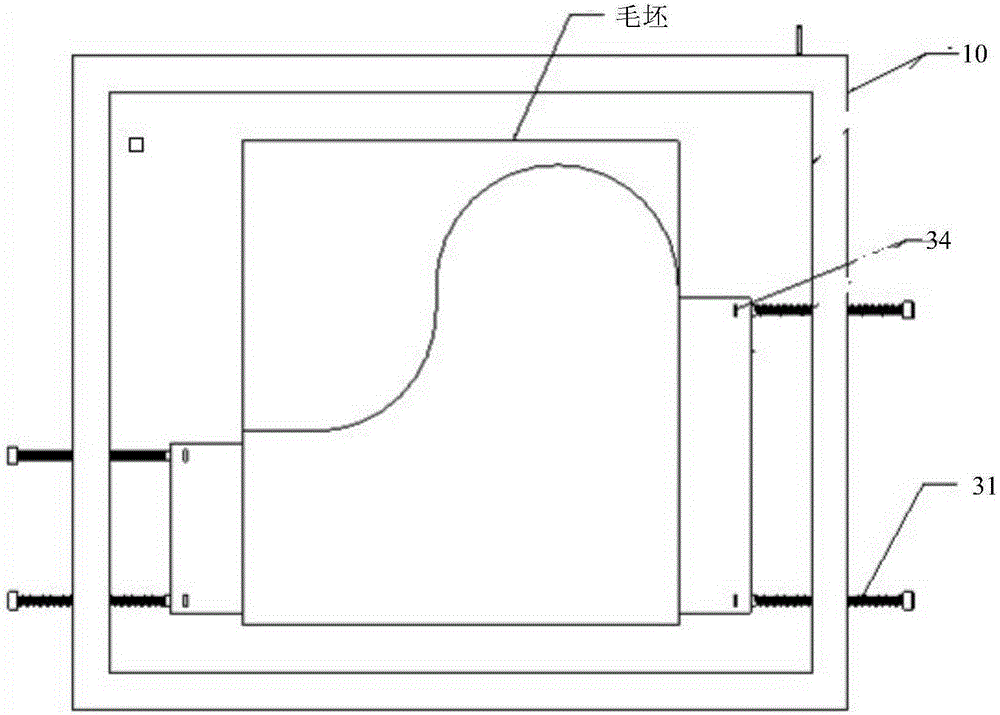

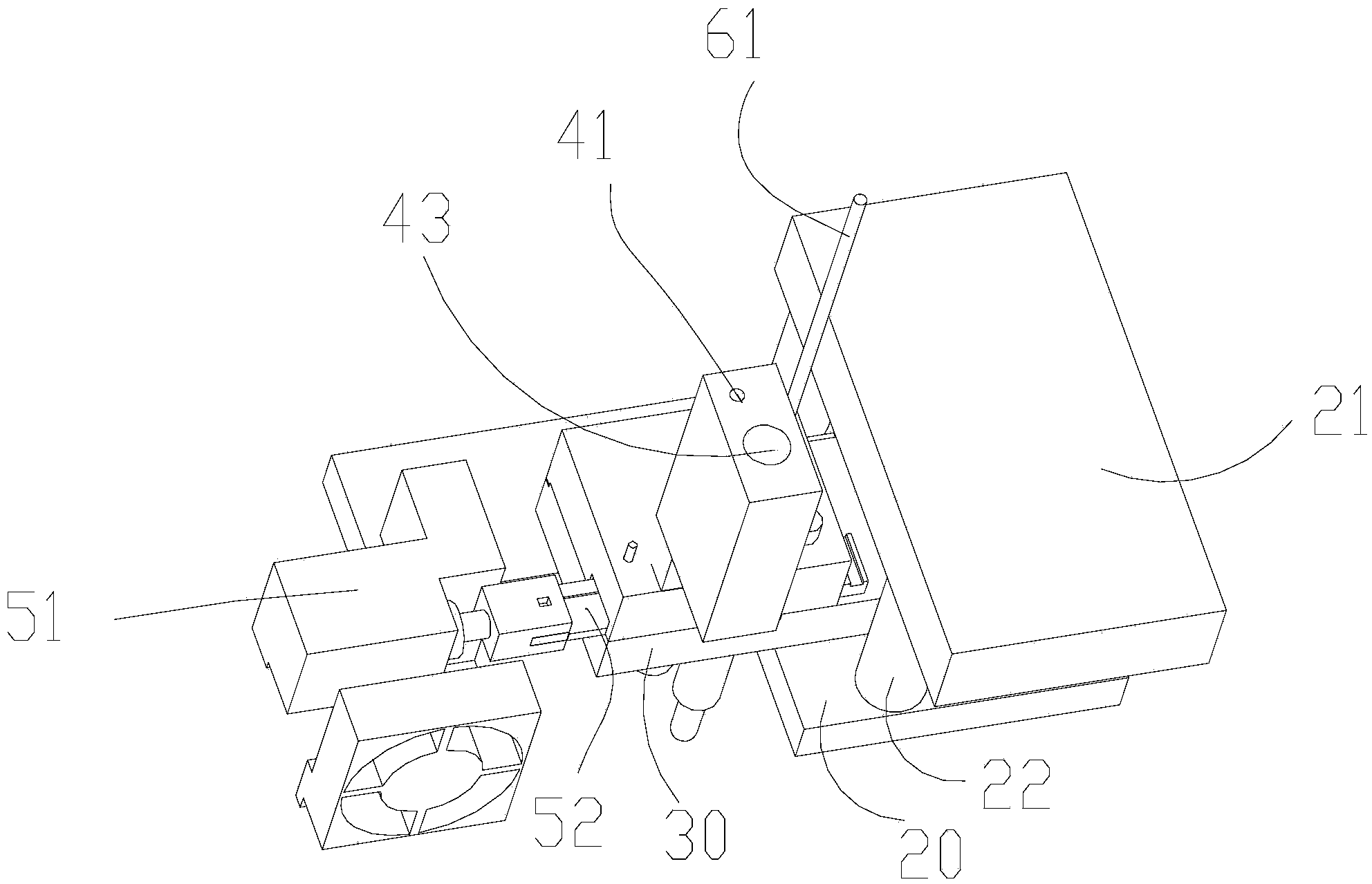

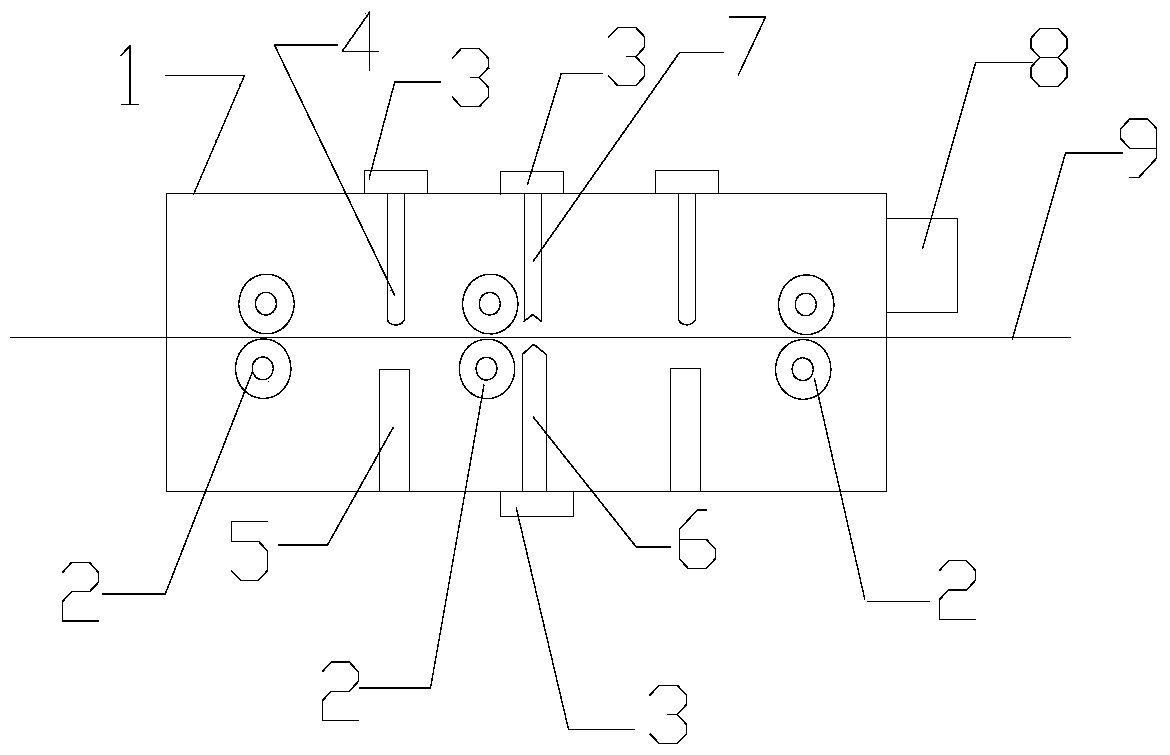

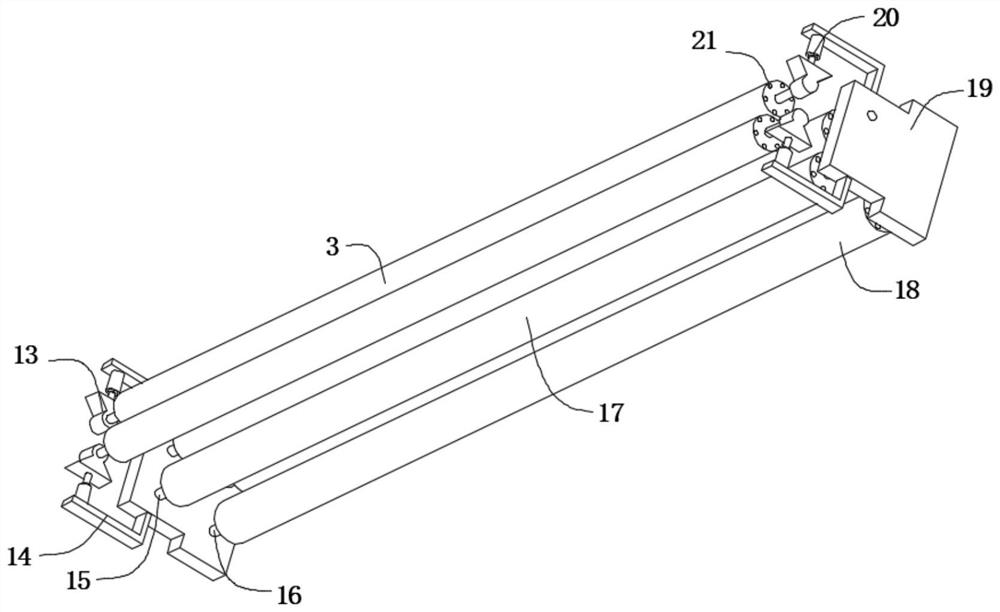

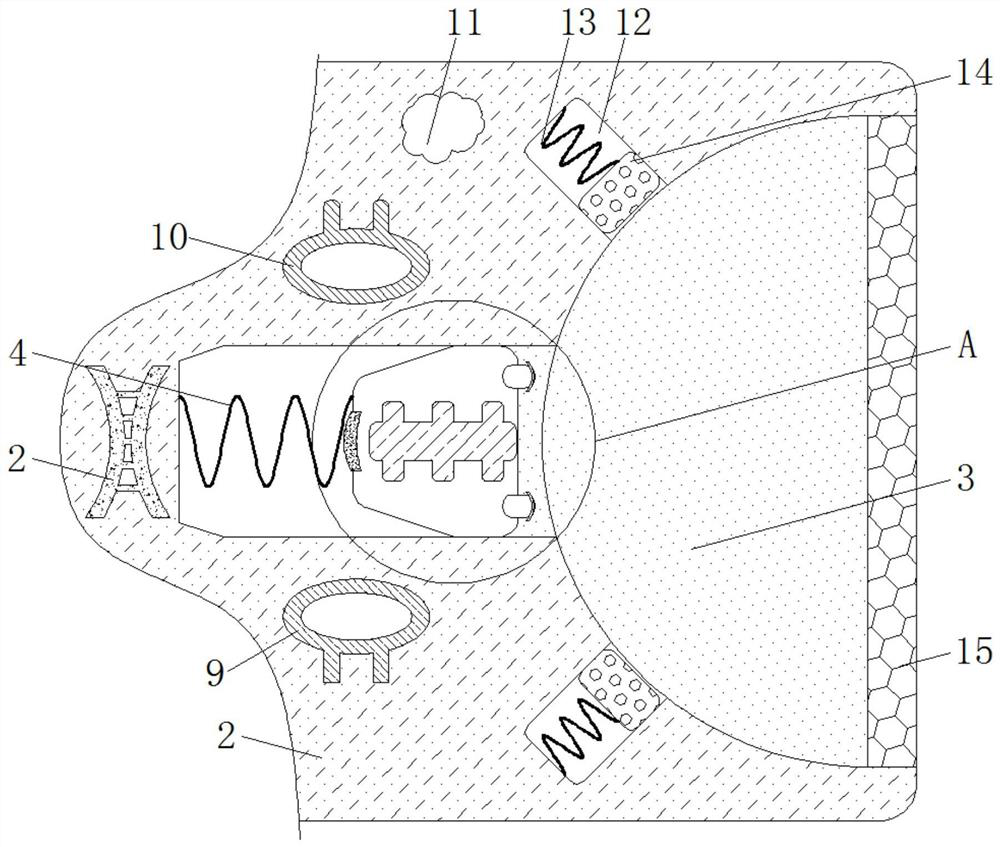

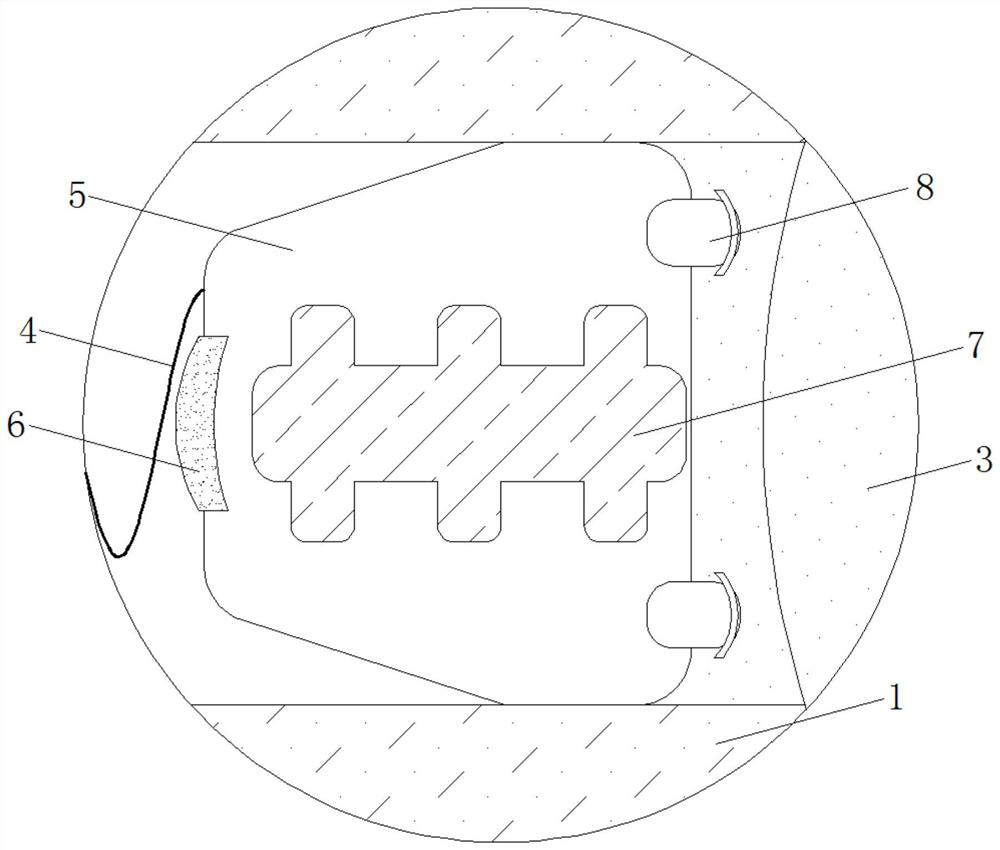

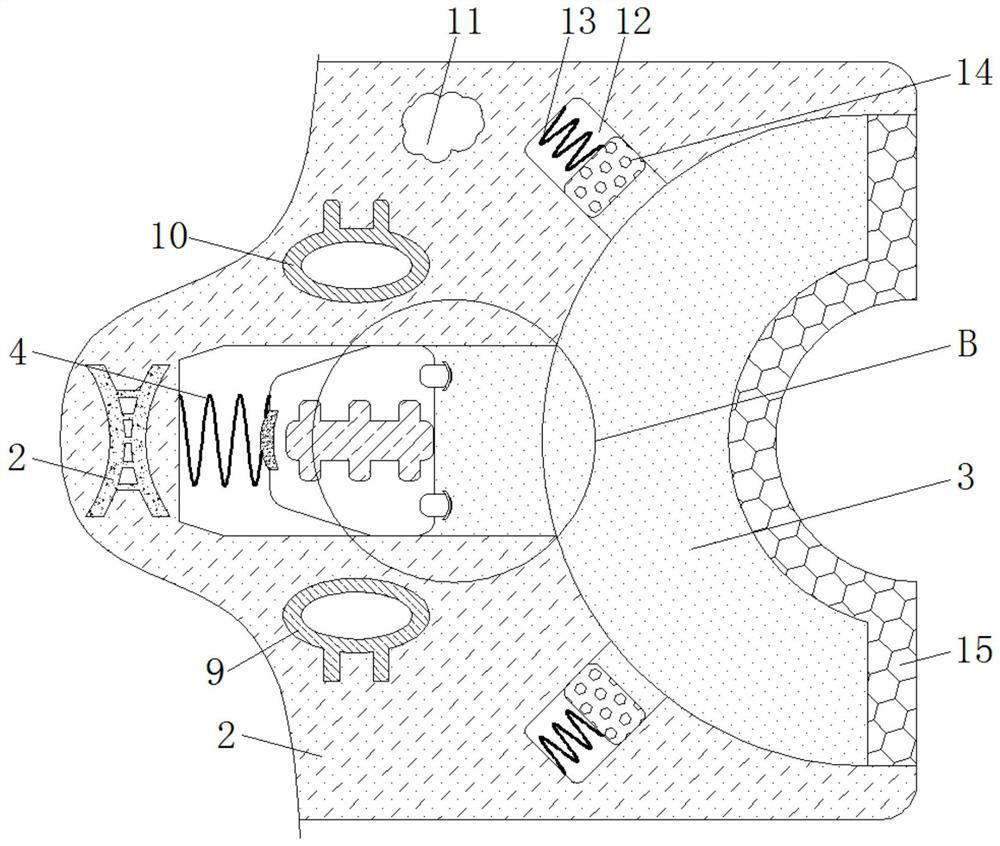

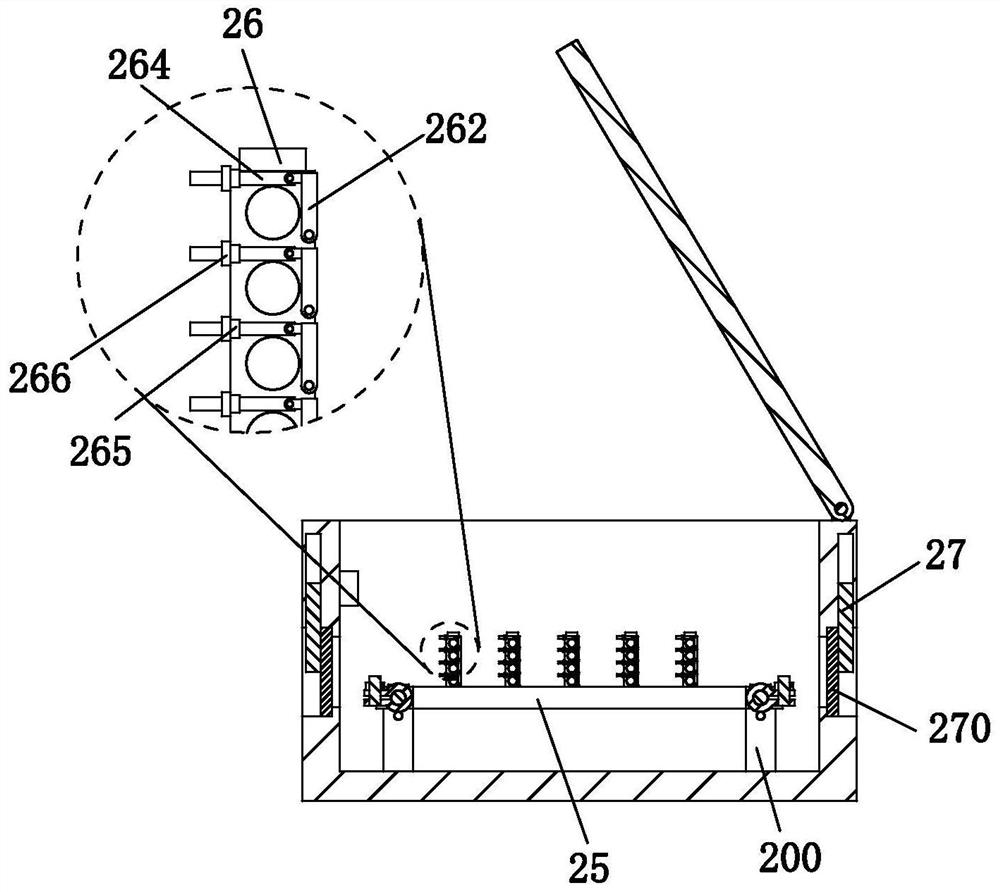

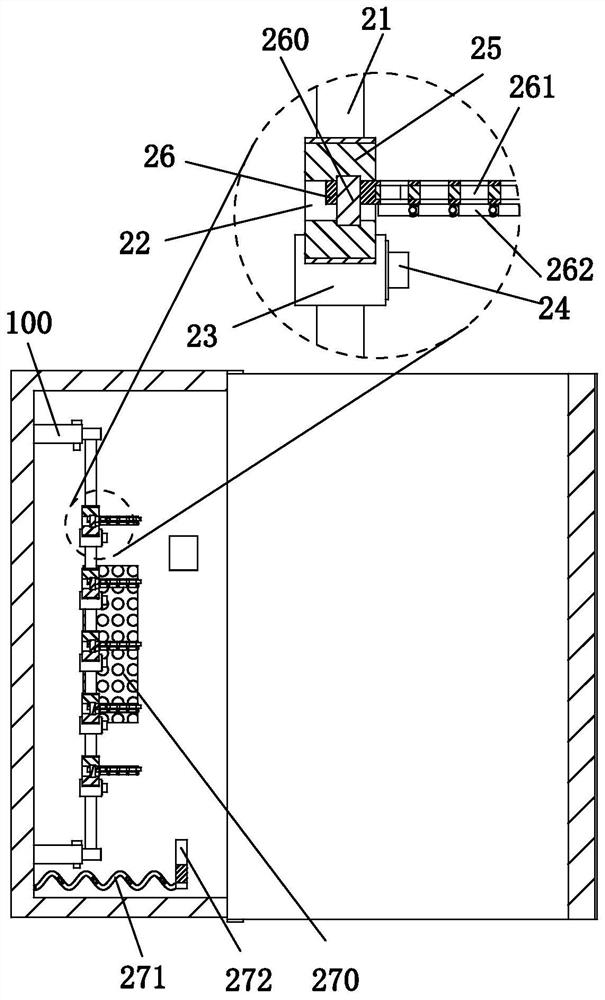

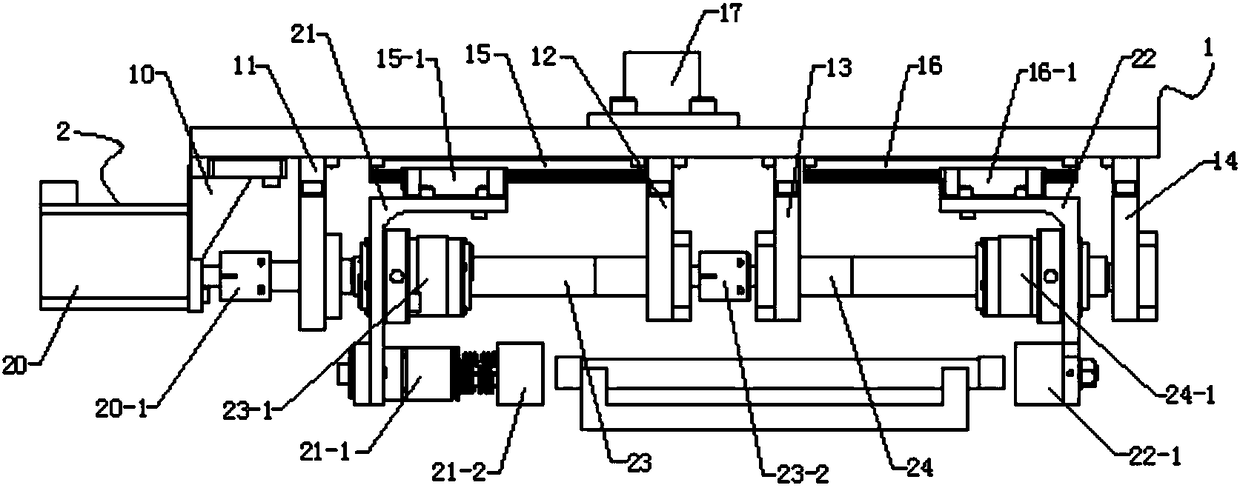

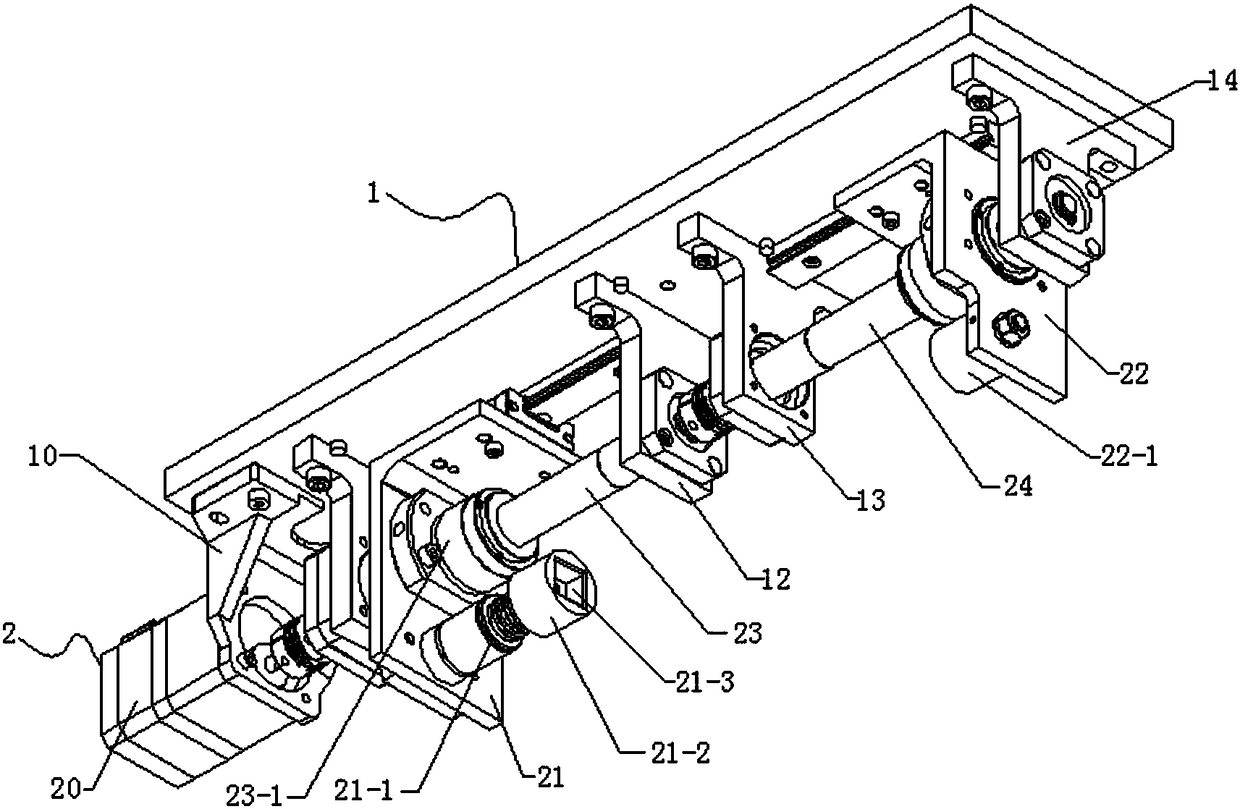

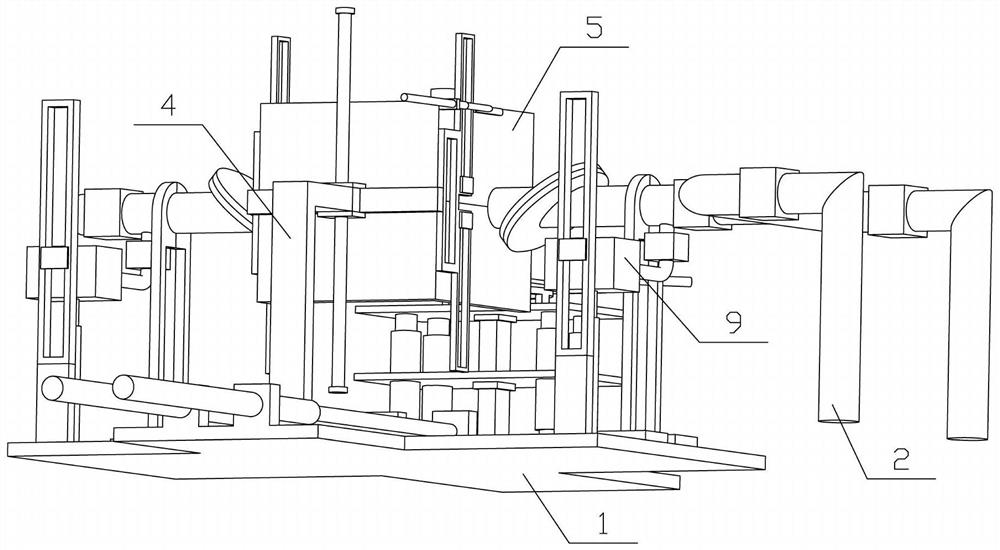

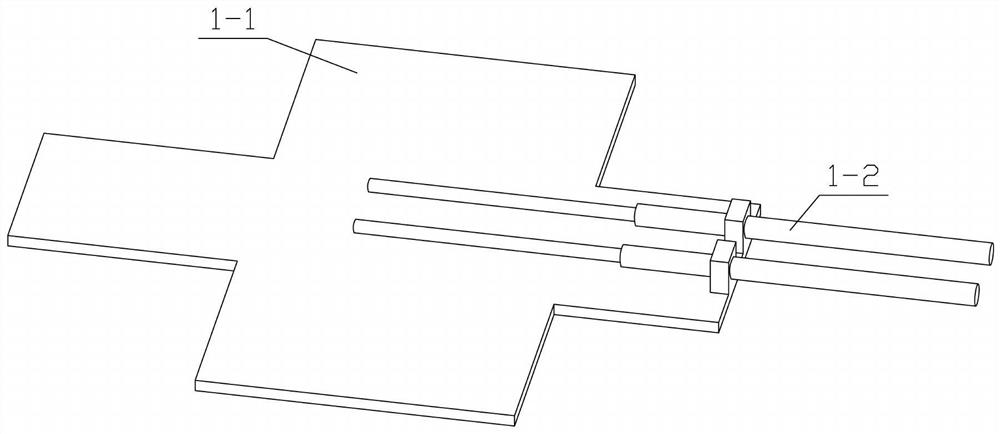

Template transmission mechanism for template-transporting sewing machine

ActiveCN103397484AEasy to moveMove fastWork-feeding meansSewing-machine control devicesGear driveDrive shaft

The invention provides a template transmission mechanism for a template-transporting sewing machine, belongs to the technical field of sewing machine manufacturing, and solves the problems of low template transmission speed, low production efficiency and the like of the conventional template transmission mechanism for the template-transporting sewing machine. The template of the template transmission mechanism for the template-transporting sewing machine is positioned at a worktable. The mechanism comprises a transmission seat, a transmission gear, a transmission shaft, a gear rack, a first drive piece and a second drive piece; the transmission gear is positioned in the transmission seat; both the first drive piece and the second drive piece are fixedly connected with the worktable; the first drive piece is connected with the transmission seat and can drive the transmission seat to move frontward and backward; the second drive piece is connected with one end of the transmission shaft; the other end of the transmission shaft is positioned in the transmission seat and is connected with the transmission gear; the gear rack is fixedly connected with the lower part of the template and is engaged with the transmission gear; and the template can translate leftward and rightward when the transmission gear drives the gear rack to translate. The template transmission mechanism for the template-transporting sewing machine has the advantages of high transmission stability, high transmission speed, high machining efficiency and the like.

Owner:ZHEJIANG ZOJE SEWING MACHINE

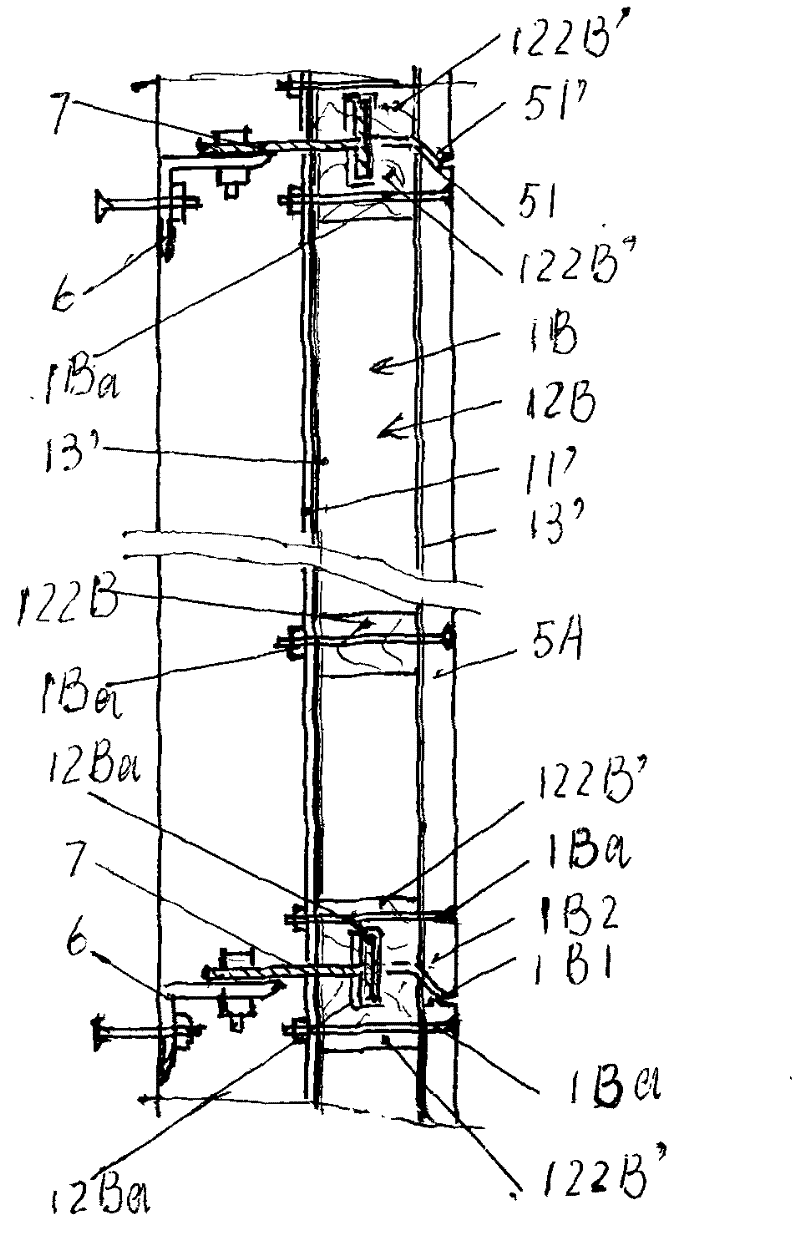

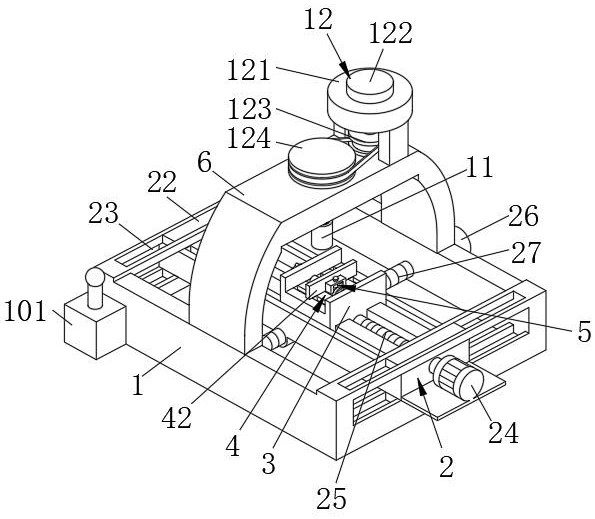

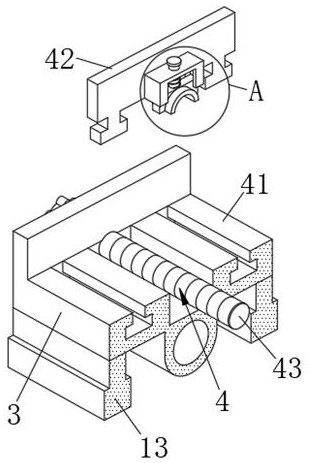

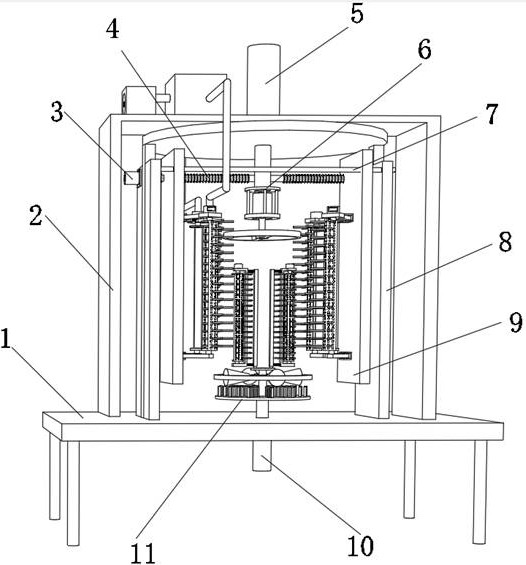

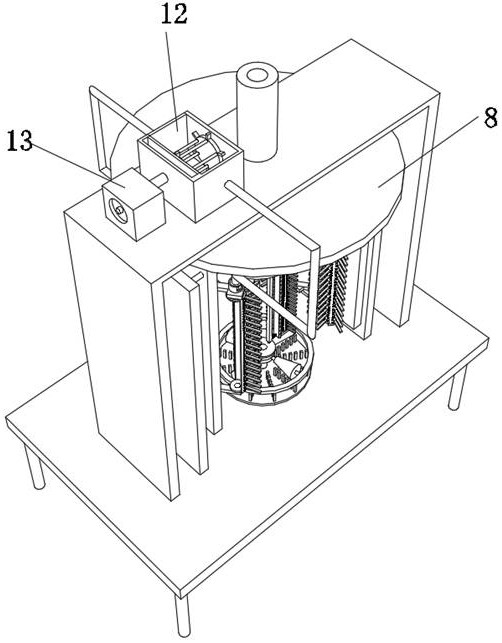

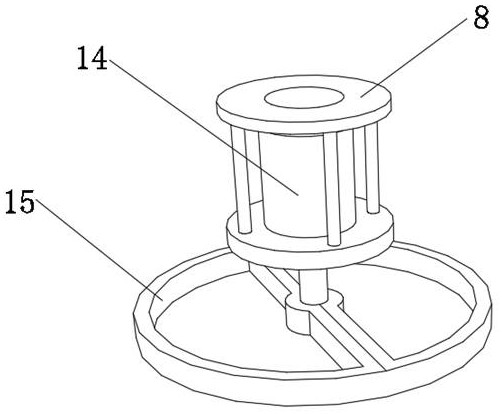

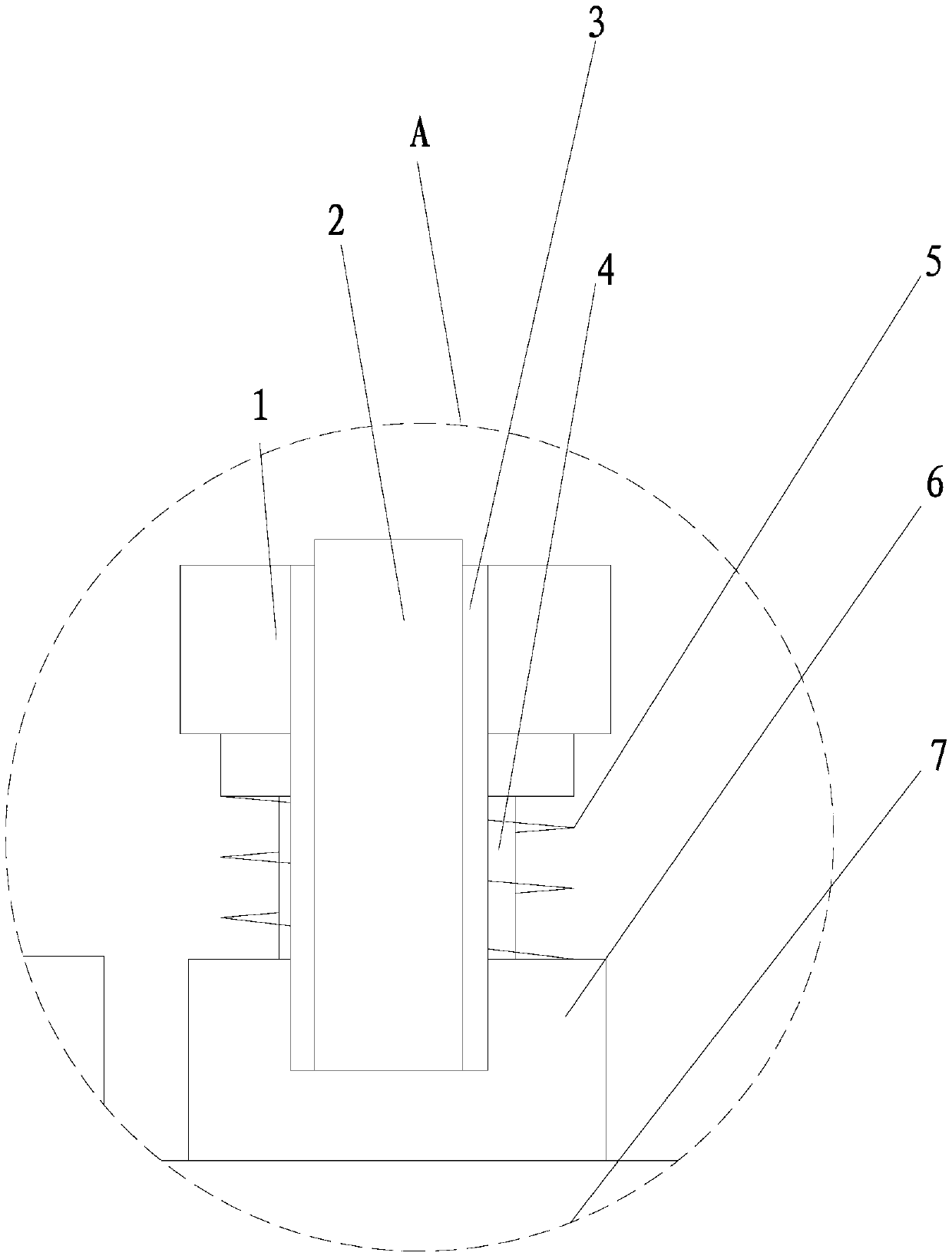

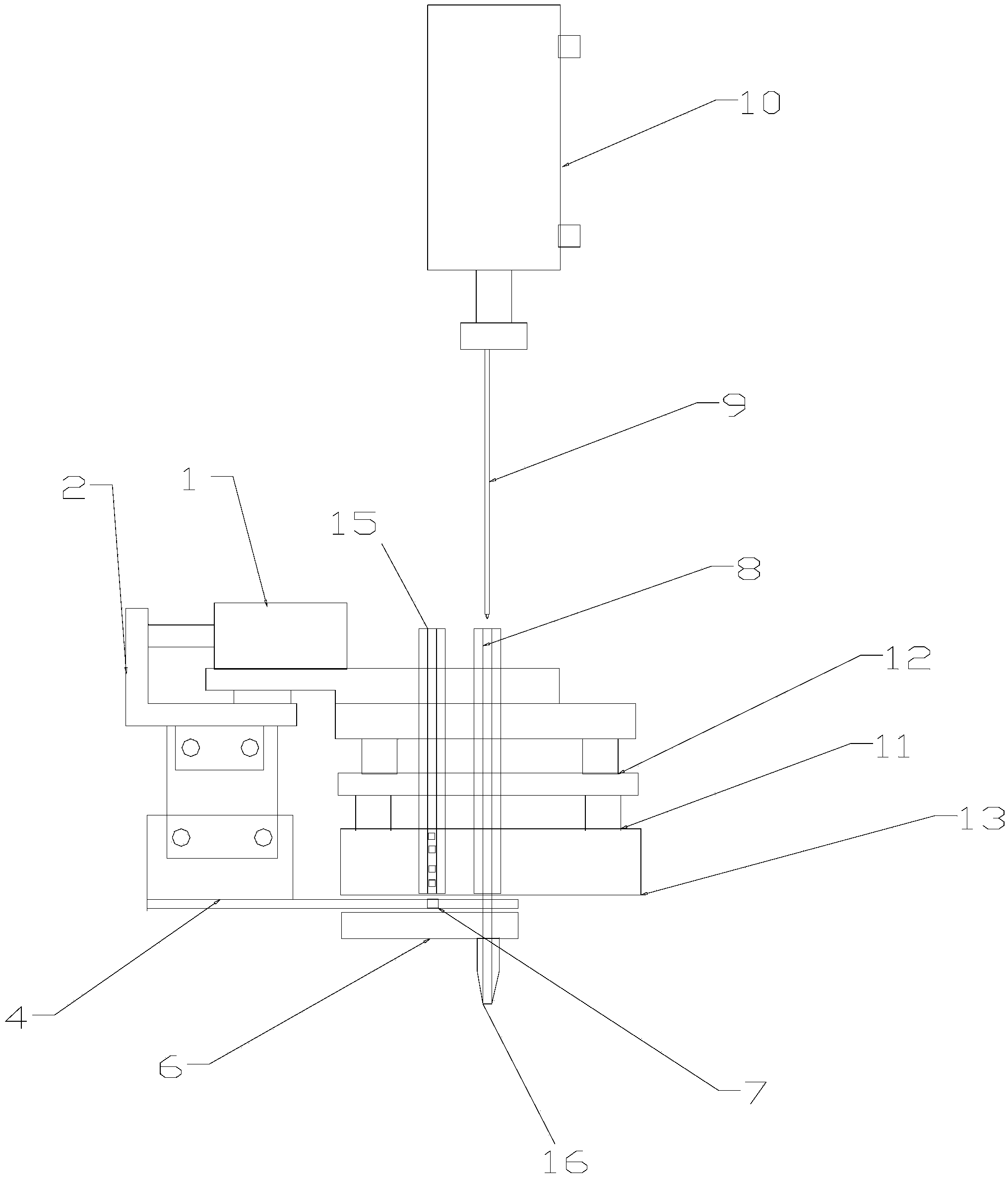

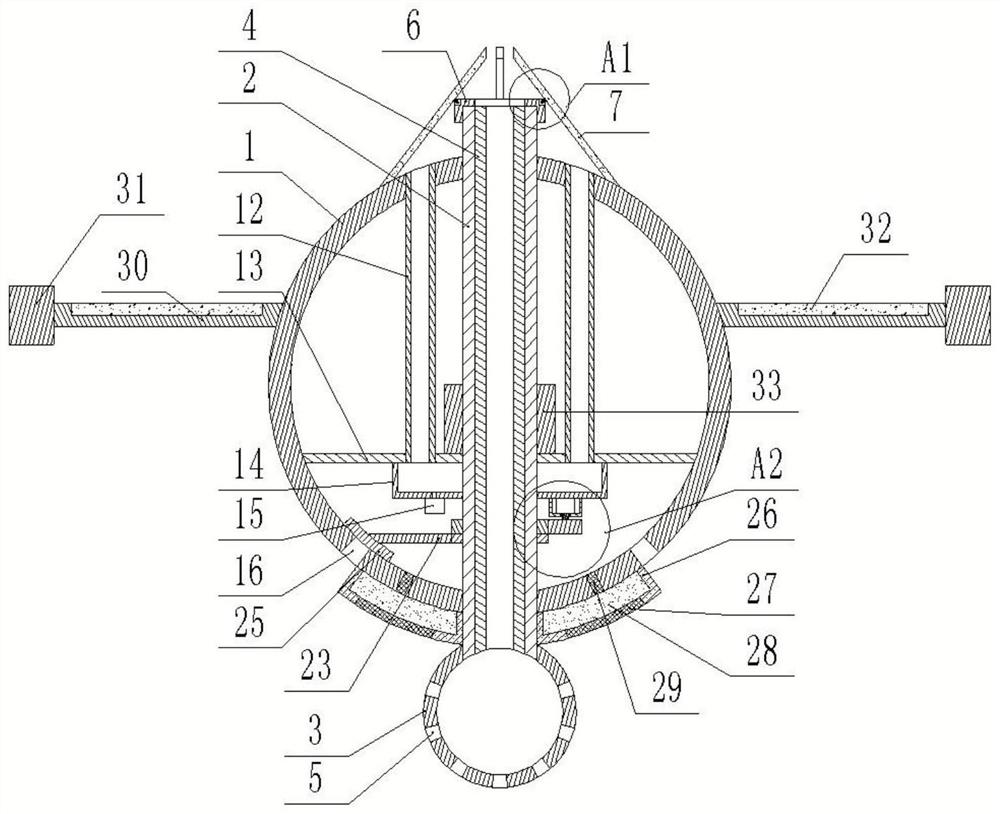

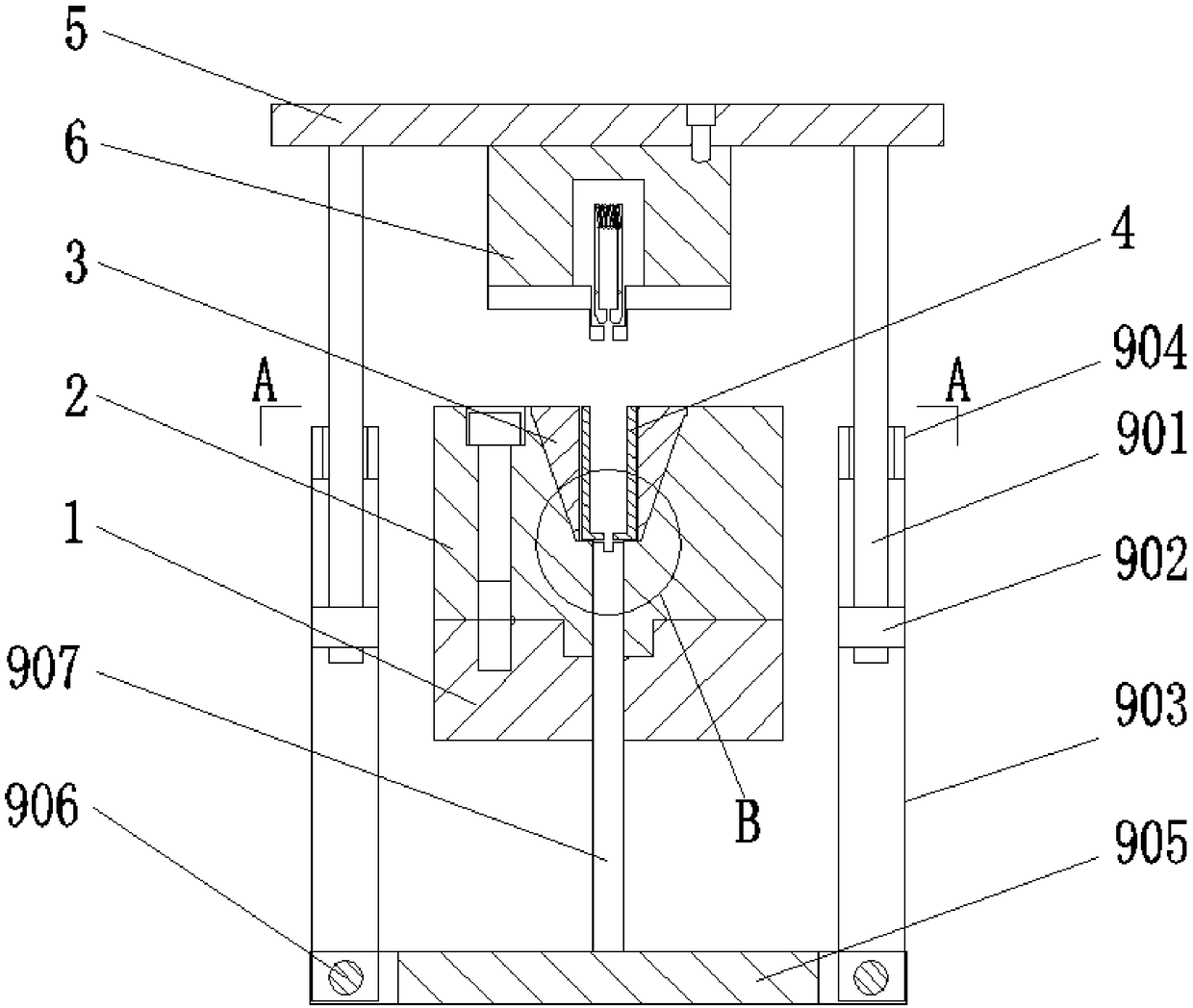

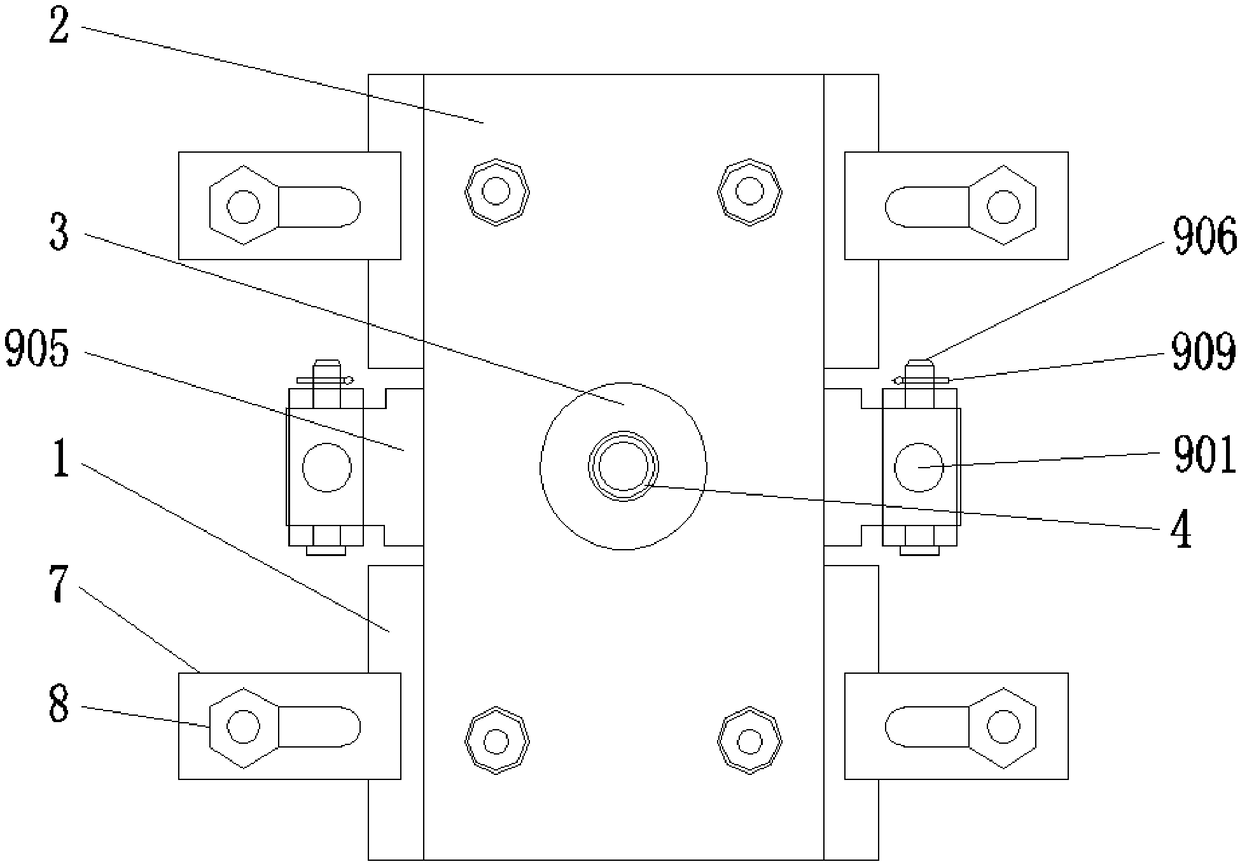

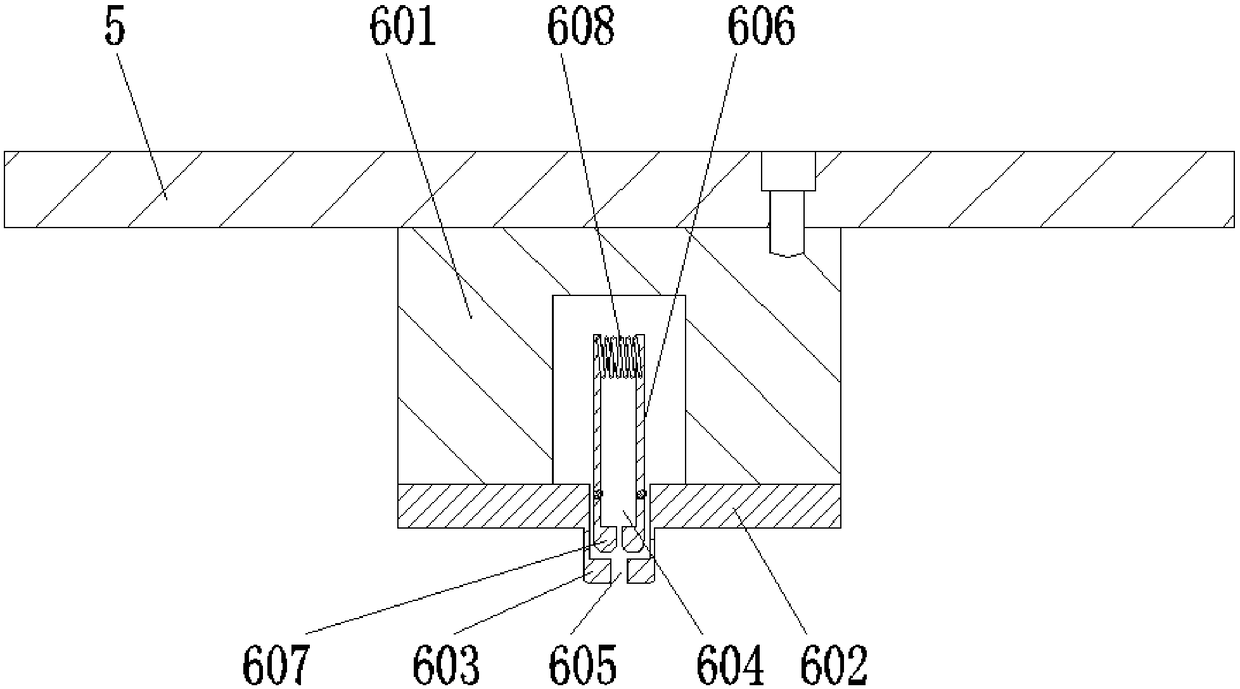

Edge face positioning device of medical needle

ActiveCN103240589AWill not deformPlay the role of clampingProgramme-controlled manipulatorMetal working apparatusManipulatorMedical device

The invention provides an edge face positioning device of a medical needle and belongs to the technical field of medical equipment. The edge face positioning device of the medical needle solves the technical problem that a needle tube deforms easily in a rotating process in the prior art. The edge face positioning device comprises a rack and rotating shafts, wherein the rotating shafts are connected with the rack in an inserted manner and can rotate freely and circumferentially; a manipulator for clamping a needle tube of a medical needle is fixed on each rotating shaft; each needle tube is positioned concentrically to each rotating shaft when the needle tube is clamped by each manipulator; and a rotating mechanism for driving the rotating shafts to rotate circumferentially is arranged between the rotating shafts and the rack. The edge face positioning device can adjust the rotation angle of each needle tube freely according to an actual condition and avoid deforming of the needle tubes.

Owner:MAIDER MEDICAL IND EQUIP

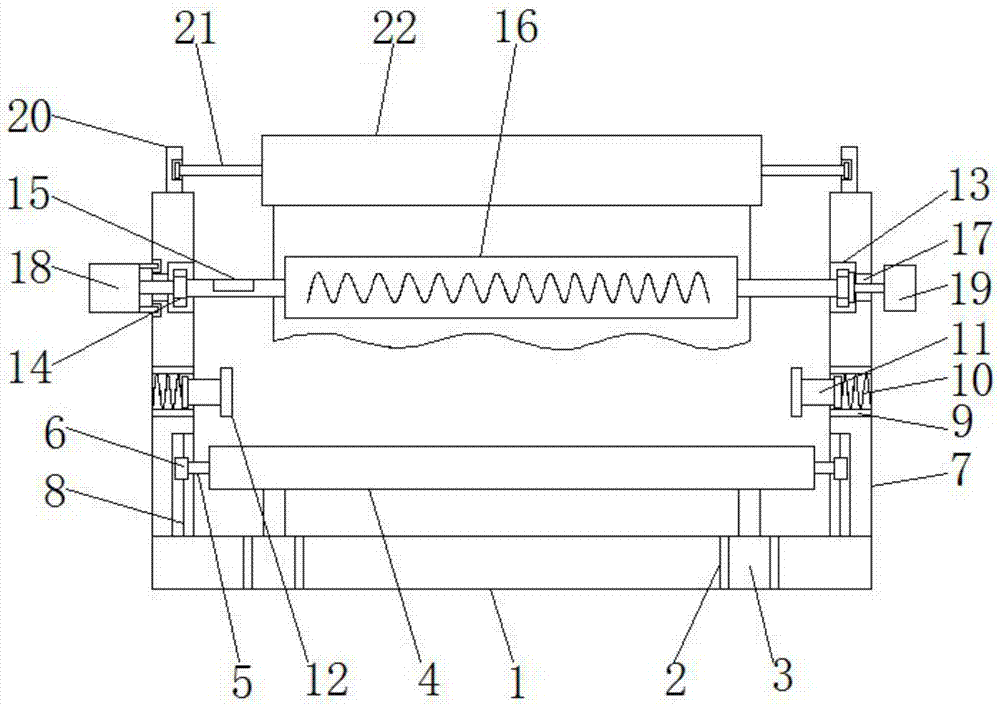

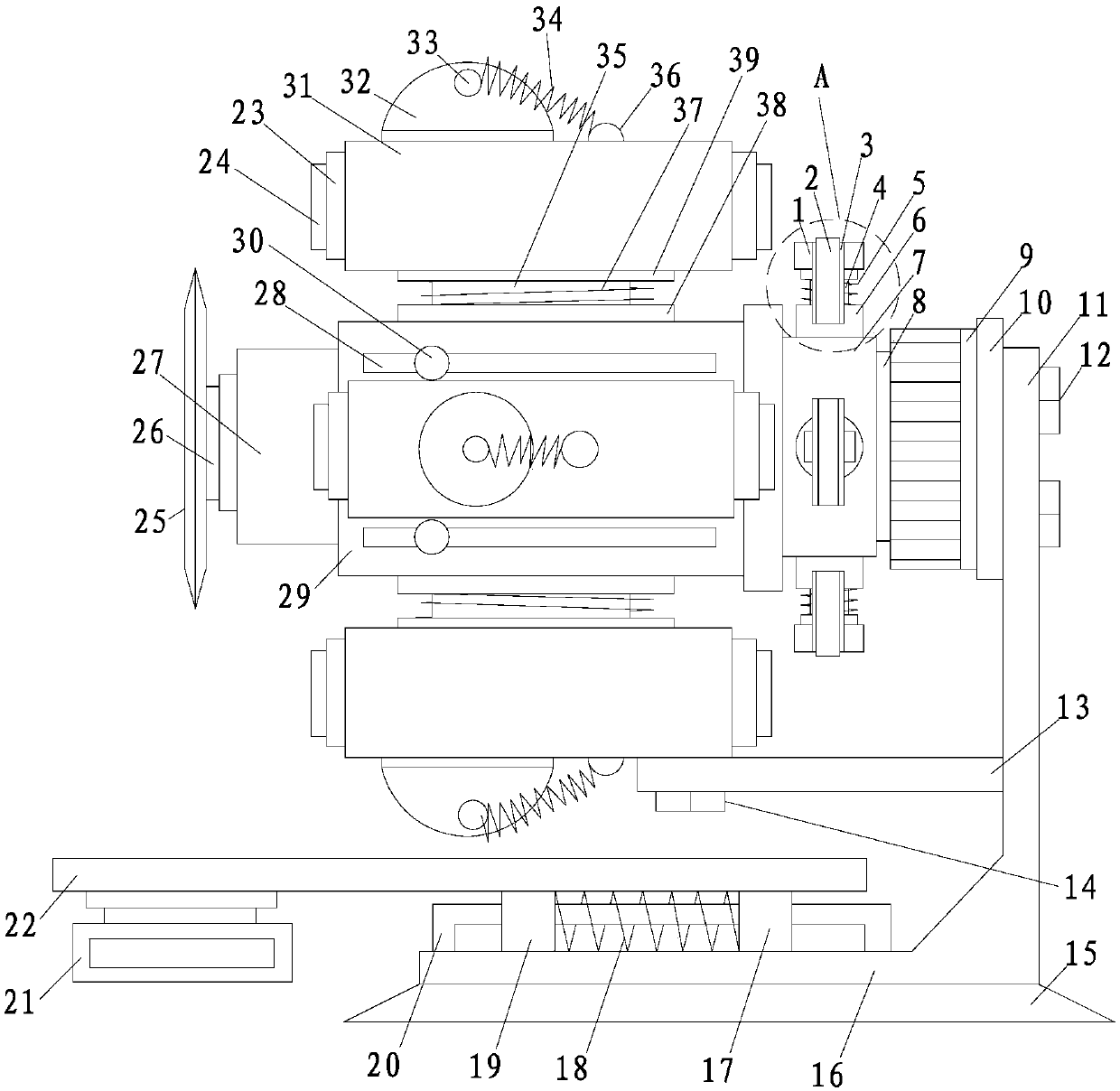

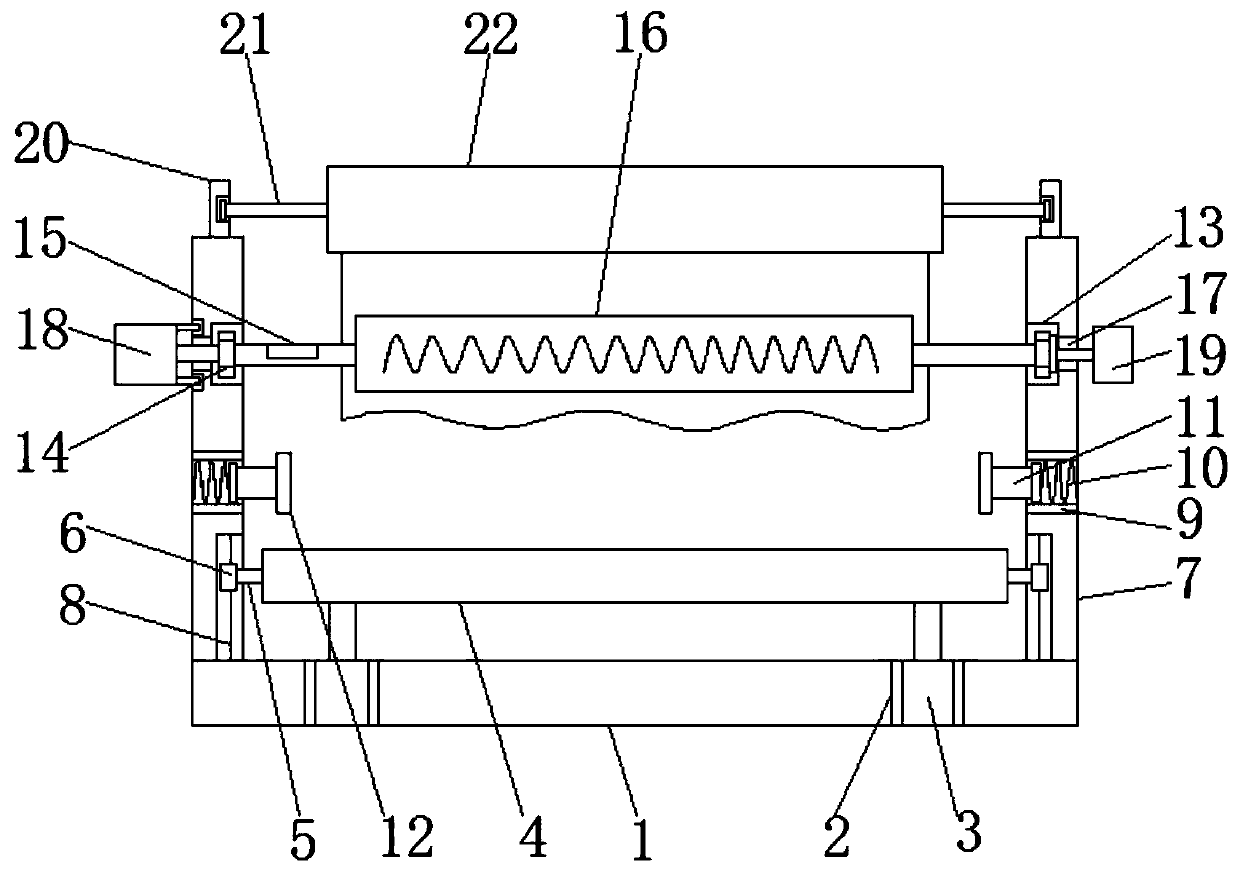

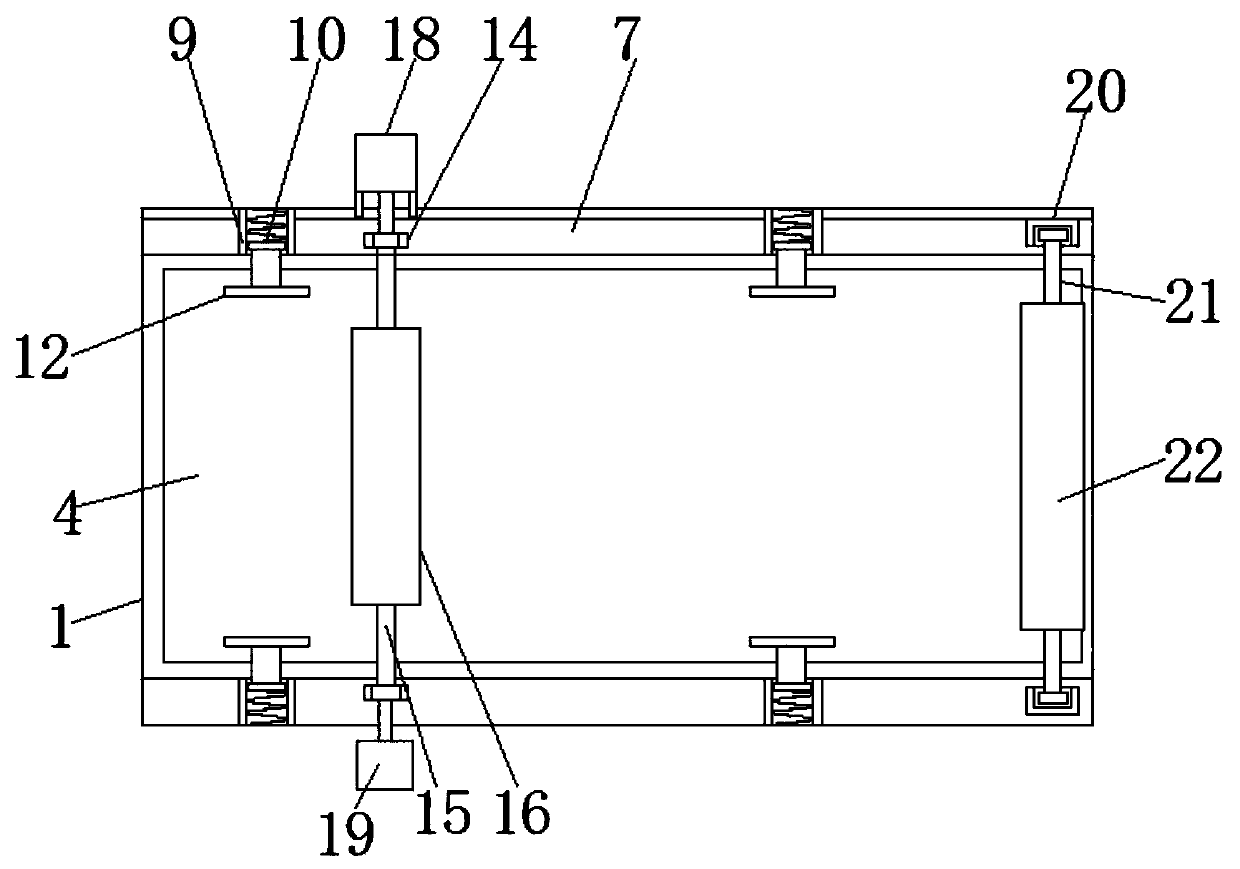

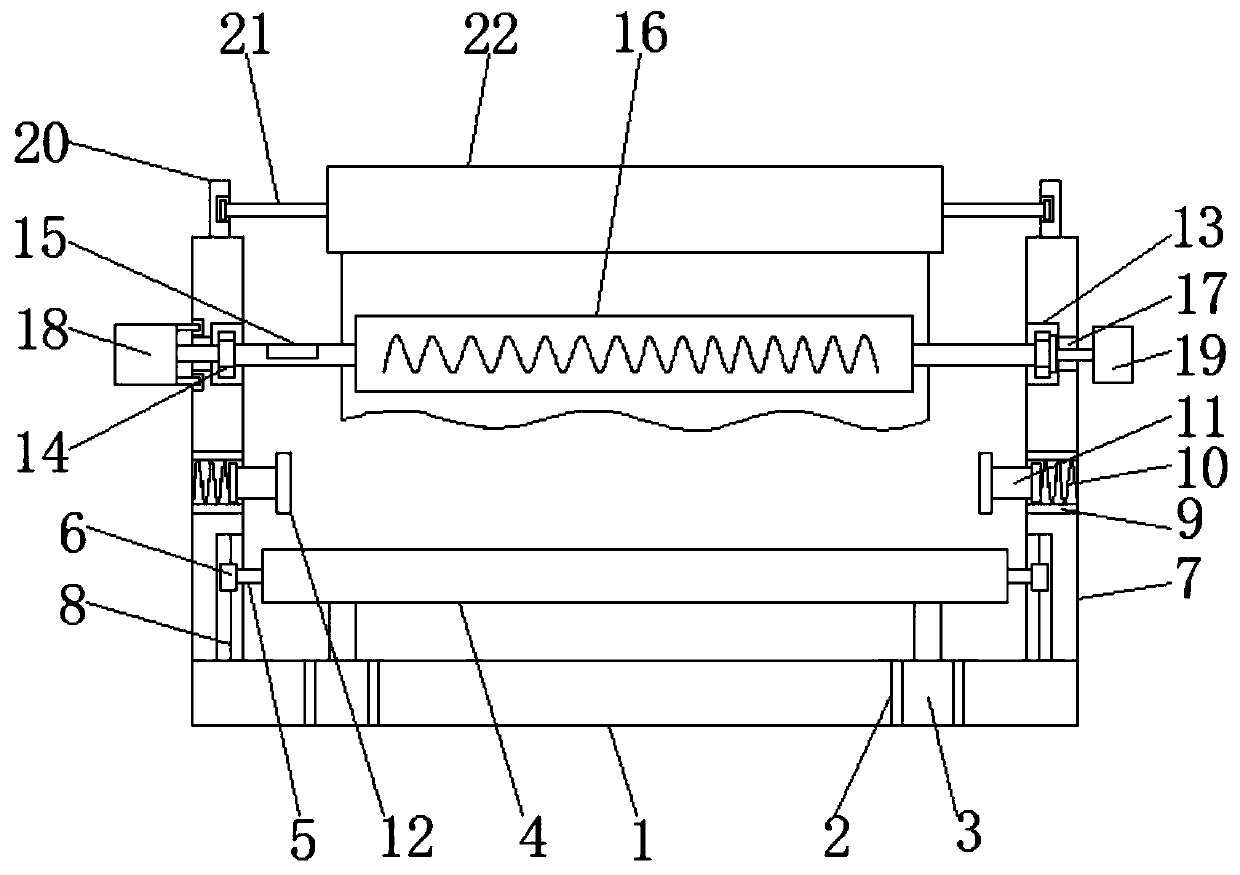

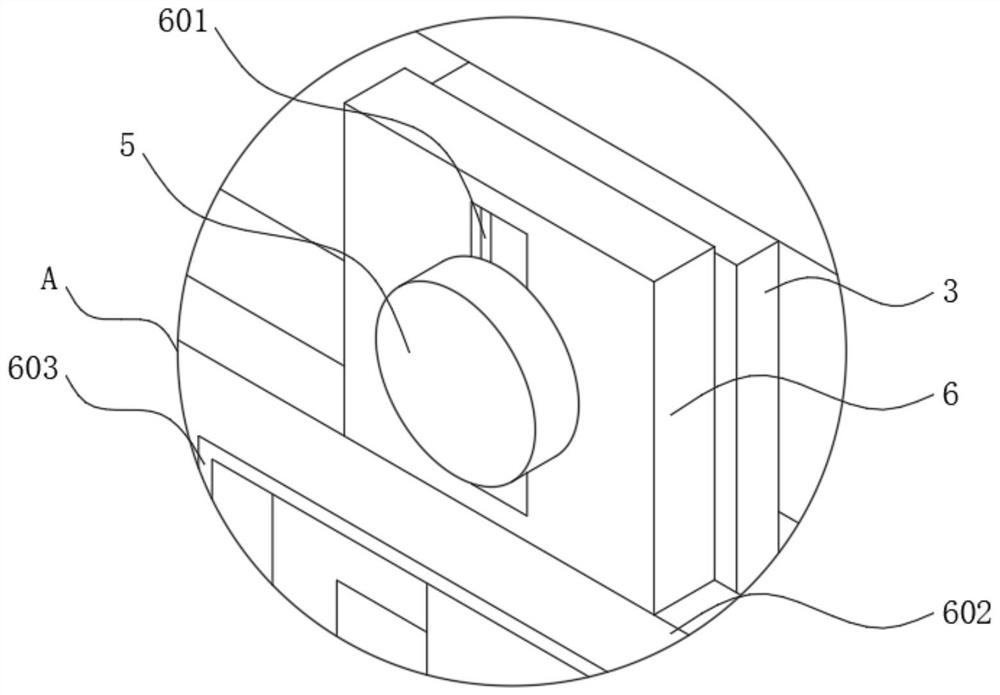

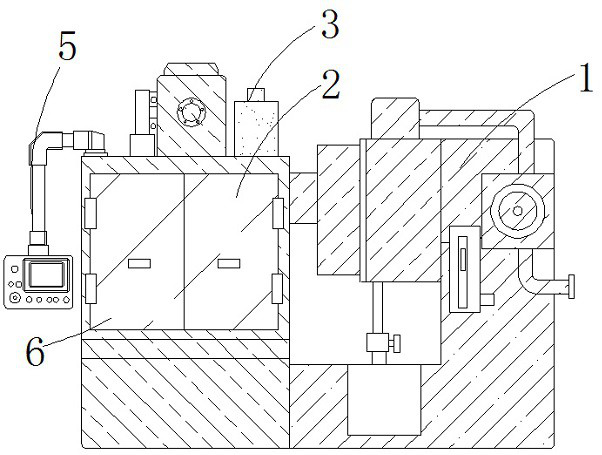

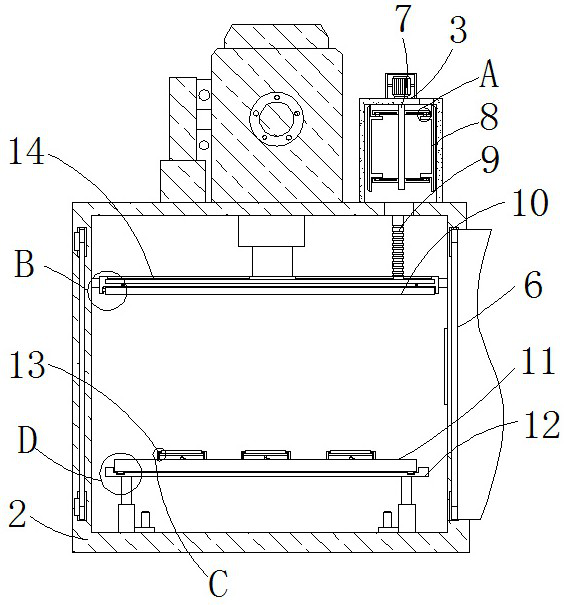

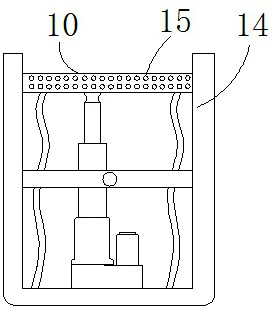

Nonferrous metal product polishing device

ActiveCN111791118AEasy to replacePlay a limiting roleGrinding wheel securing apparatusGrinding carriagesMachine partsNonferrous metal

The invention discloses a nonferrous metal product polishing device. The nonferrous metal product polishing device comprises a machining table, an orientation adjusting mechanism is arranged in an inner cavity of the machining table, the orientation adjusting mechanism comprises a sliding plate slidably connected with the inner cavity of the machining table, and guide sliding blocks are fixedly connected with the front side and the rear side of the top and the front side and the rear side of the bottom of the sliding plate correspondingly; guide sliding grooves matched with the guide sliding blocks are formed in the front side and the rear side of the top of the machining table correspondingly; and a longitudinal driving motor is fixedly connected with the rear side of the sliding plate. According to the nonferrous metal product polishing device, through cooperative use of a clamping device and a clutch mechanism, a machined part is clamped; through cooperative use of a fixing block and a limiting mechanism, the applicable polishing rod is installed; then the polishing rod is driven to rotate through arrangement of the driving mechanism, finally through arrangement of the orientation adjusting mechanism, the direction of the machined part is adjusted, and polishing is conducted through the polishing rod; and the purposes of conveniently replacing the polishing tool, conveniently clamping and polishing in multiple directions can be achieved.

Owner:罗静婷

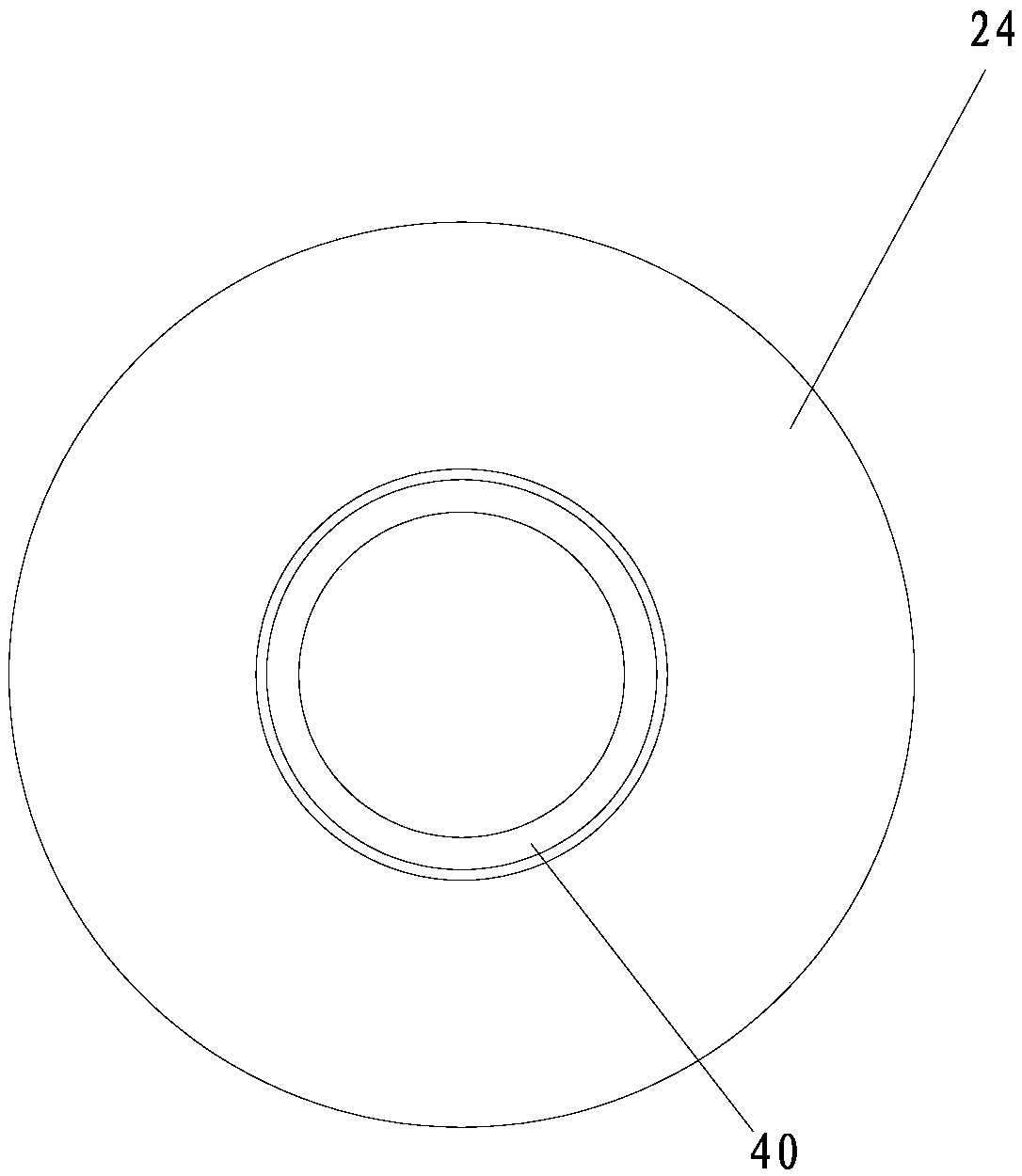

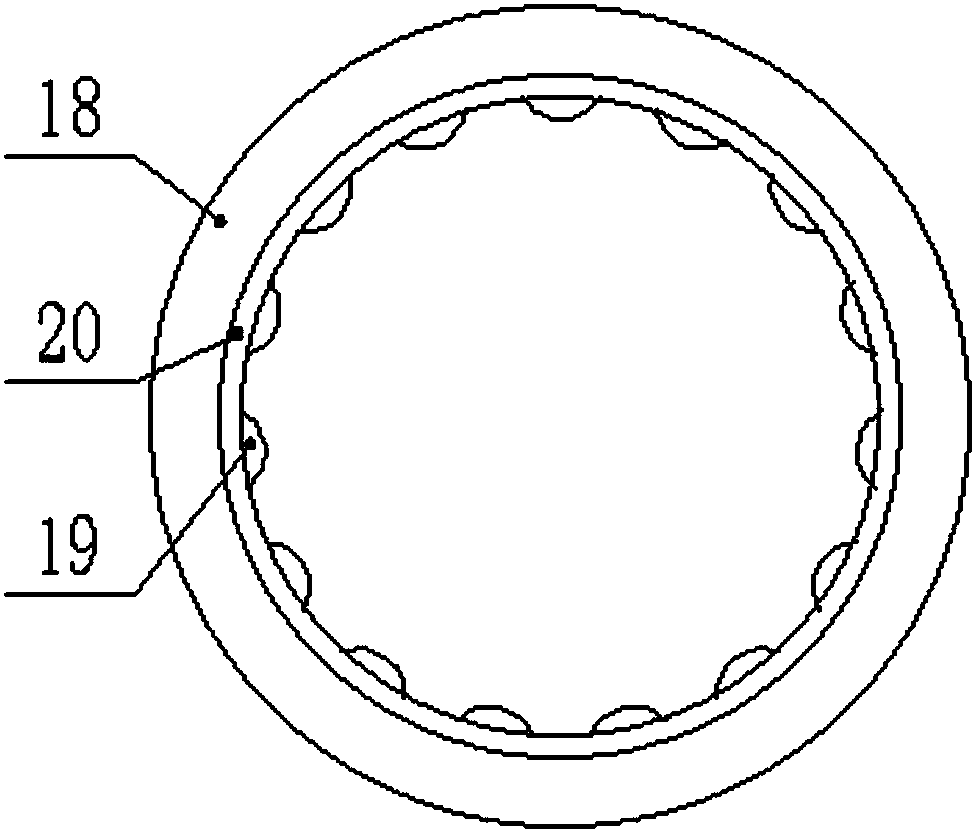

Gas insulated power transmission line

InactiveCN106953241APlay the role of clampingAvoid damageBus-bar/wiring layoutsTotally enclosed bus-bar installationsTransmission lineEngineering

The invention discloses a gas insulated power transmission line, including a plurality of connected pipeline units. Each pipeline unit comprises a shell, basin-type insulators arranged at two ends of the shell, a conductor passing through the basin-type insulators and insulated compression gas arranged between the shell and the conductor. The conductor is externally provided with a protective sleeve in a sleeving manner. The protective sleeve passes through the two basin-type insulators, and forms sealing cooperation with the basin-type insulators. The inner wall of the protective sleeve is provided with a clamping element which abuts against the conductor under the action of the insulated compression gas in the shell to achieve fixation of the conductor. When the conductor is assembled, the clamping element does not extrude the conductor, so that the phenomenon that the conductor is worn in the installation is avoided to a certain extent.

Owner:上海华东电器集团电气有限公司

Deburring device for motor shell production

InactiveCN112405196APlay the role of clampingGuaranteed removal effectEdge grinding machinesRevolution surface grinding machinesElectric machineEngineering

The invention discloses a deburring device for motor shell production, relates to the technical field of motor shell deburring devices, and aims to reduce burr cleaning dead angles. The deburring device specifically comprises a base, a motor shell and a reverse distance adjusting mechanism, two moving plates are slidably connected to the outer wall of the distance adjusting mechanism, two rotatingframes are fixed to the inner wall of one side of each of the two moving plates through bolts, and two connecting rods are rotatably connected to the inner wall of each of the two rotating frames through rotating shafts; and the inner walls of one sides of the two connecting rods located on the same side are rotationally connected with the same first hole-shaped brush roller, and the outer wallsof one sides of the two connecting rods located on the two sides are connected with the same tension spring in a clamped mode. By arranging the four first hole-shaped brush rollers, the circumferential outer walls of the moving plates can play a role in clamping the circumferential outer wall of the motor shell in the moving process of the moving plates, and therefore burrs on the circumferentialouter wall of the motor shell can be removed through brushes arranged on the circumferential outer walls of the first hole-shaped brush rollers.

Owner:龚爽

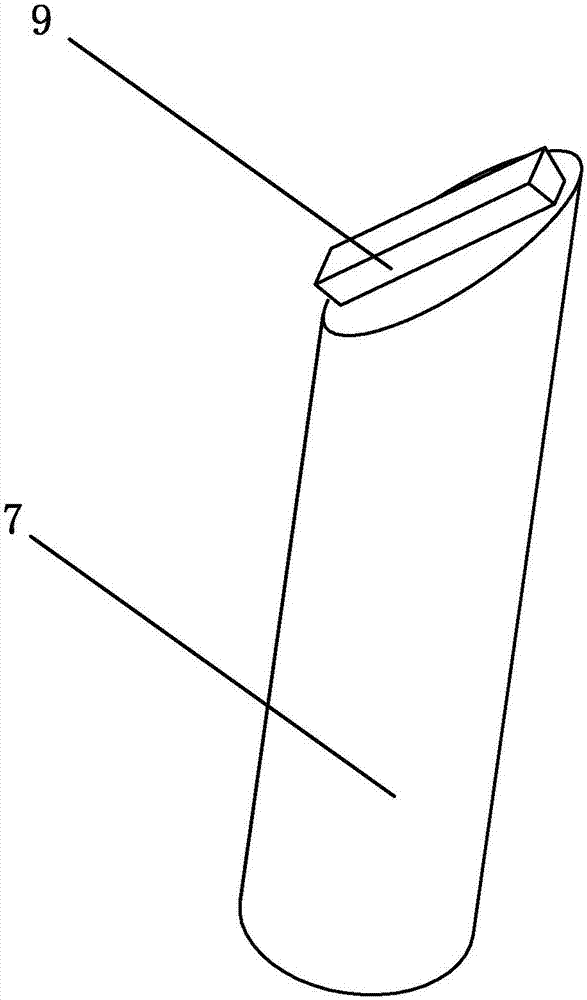

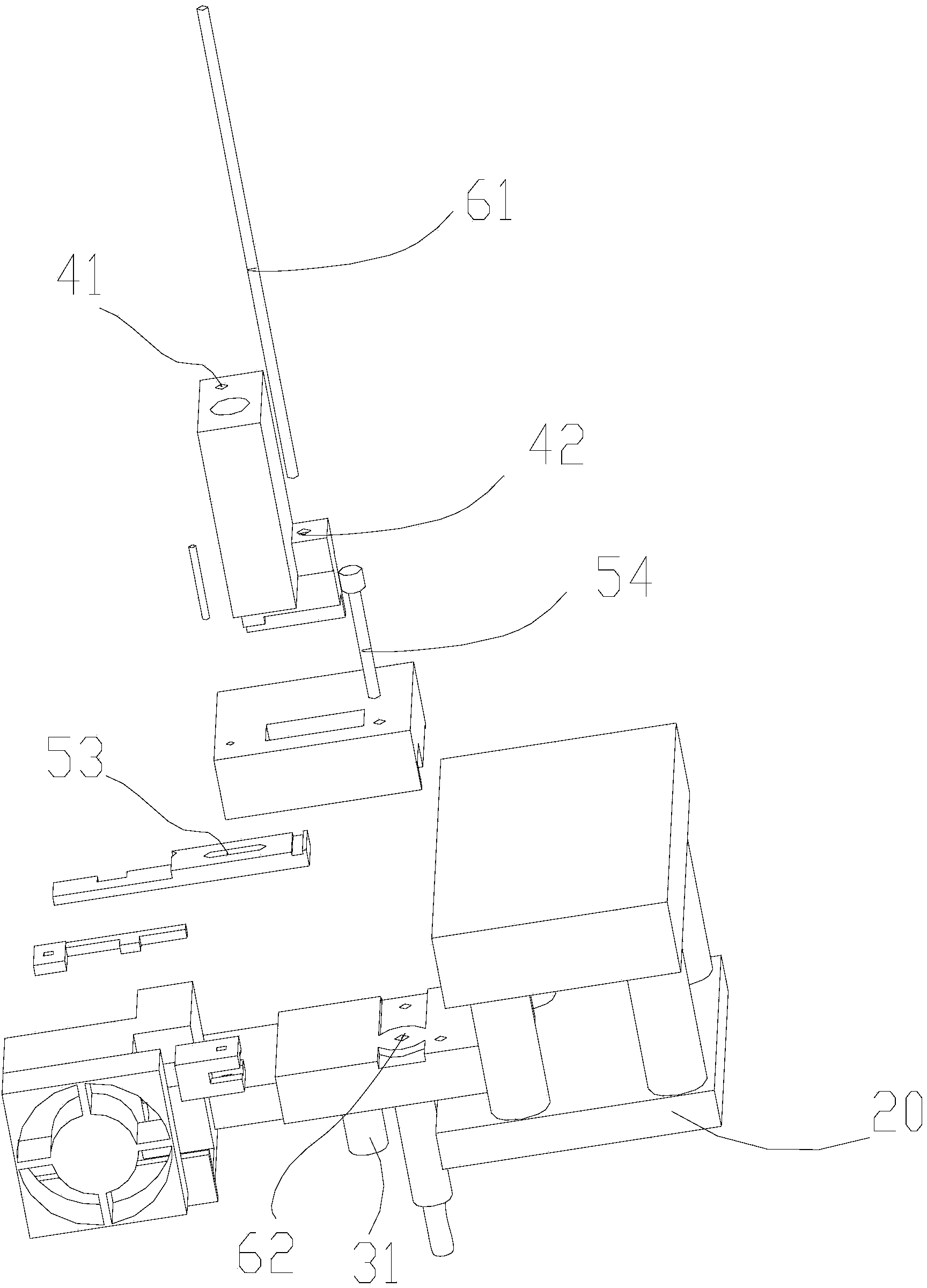

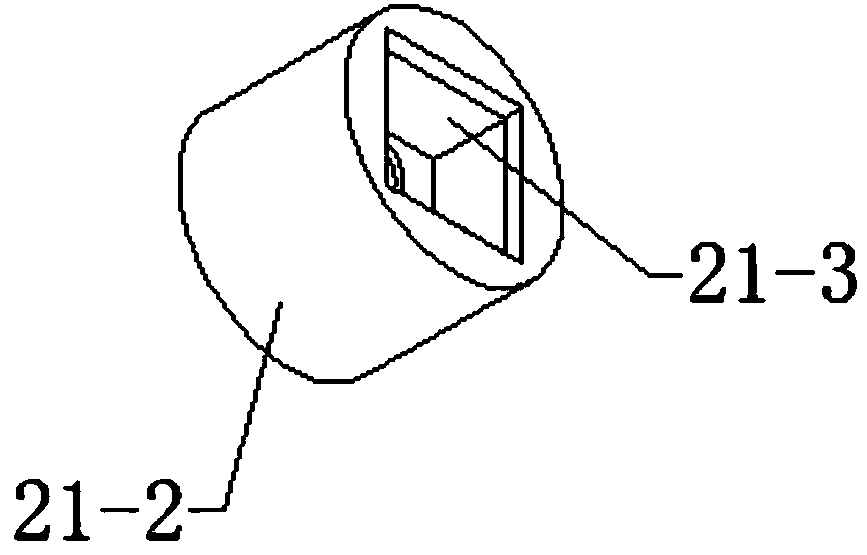

Drill bit storage device convenient for personnel to take for machining

InactiveCN111843607AEasy accessAutomatic clampingProtection and storage accessoriesWork tools storageMachining processDrill bit

The invention provides a drill bit storage device convenient for personnel to take for machining, relates to the technical field of machining, and aims to solve the problems that in the machining process, due to the fact that drill bits are placed in a storage box, when the drill bits are taken, the storage box needs to be opened for selection, moreover, the drill bits are placed in the box and also need to be clamped by a clamping mechanism, the drill bits are abraded due to collision, and in the machining process, the drill bits of different specifications and models need to be selected foruse according to the sizes of drilled holes, and due to the fact that the diameters and the lengths of the drill bits of different specifications are inconsistent, the drill bits are difficult to clamp through the same set of clamping tool. The drill bit storage device comprises a base; a rotating mechanism is transversely and rotationally mounted at the upper end of the middle of the base. According to the drill bit storage device, due to the fact that a bearing rod is vertically and fixedly mounted in the middle of the lower end of a bearing mechanism, the lower end of the bearing rod is inserted into a sliding assembly in a sliding mode, the drill bits can be conveniently taken and placed, the drill bits can be automatically clamped after being placed under the combined action of the bearing rod and a spring, and convenience and rapidness are achieved.

Owner:倪波者

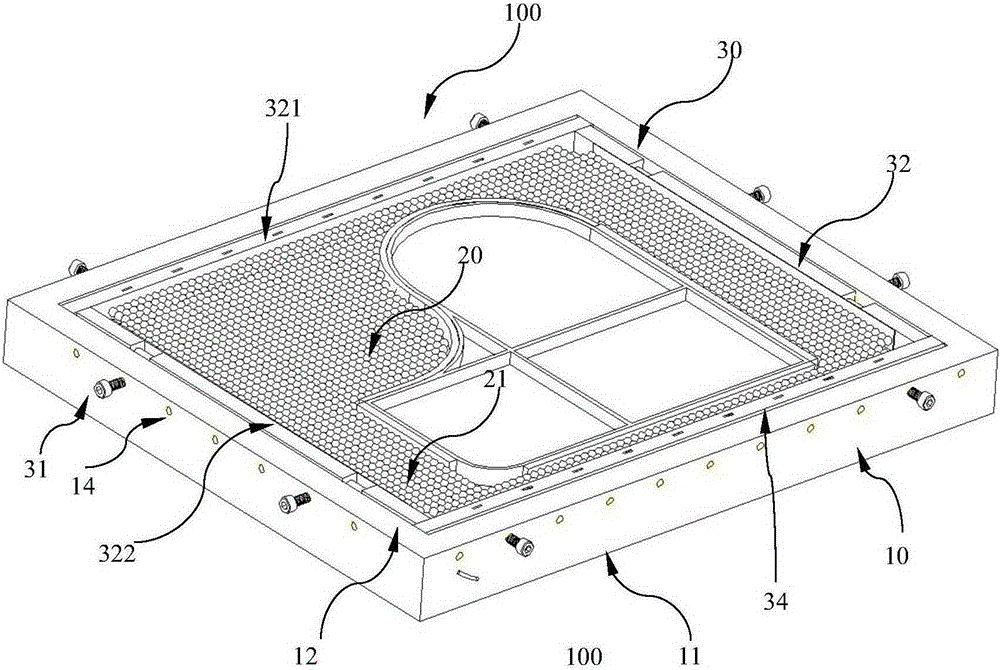

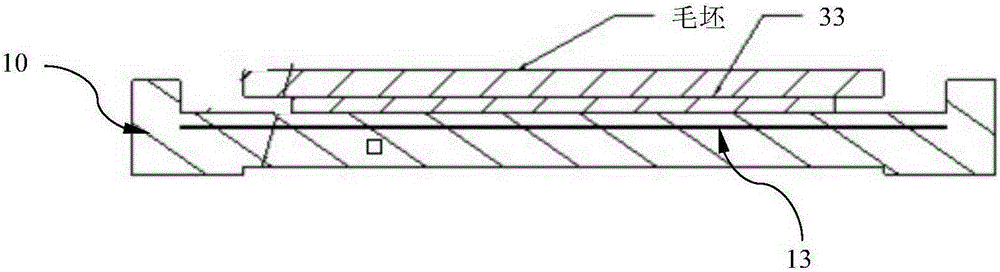

Clamping device and method for thin-walled frame type parts

ActiveCN105269354AStrong size applicabilityGuaranteed stabilityPositioning apparatusMetal-working holdersEngineeringNon magnetic

A clamping device for thin-walled frame type parts is used for clamping and fixing the non-magnetic thin-walled frame type parts to be machined when the parts are machined. The clamping device is characterized in that the device comprises a bottom plate portion and a position limiting portion; the bottom plate portion is in the shape of a groove with the upper part open and used for accommodating the parts to be machined; the bottom plate portion comprises a bottom and side edges, the bottom is hollow, and an electromagnet is arranged in the bottom and used for generating magnetic force after being powered on; the position limiting portion is arranged in the bottom plate portion and comprises a plurality of balls made of materials capable of being magnetized, and the balls are fixed at preset positions under the magnetic force effect and used for limiting the positions of the parts to be machined. Meanwhile, the invention provides a method used for clamping the parts through the clamping device for the thin-walled frame type parts.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Steel pipe cutting machine

PendingCN109513984AImprove protectionPlay the role of clampingTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to a steel pipe cutting machine. The steel pipe cutting machine comprises a rack, a first motor, a rotating drum, friction assemblies, an installing drum rotatably arranged in the rotating drum in a matched mode, sleeves, a rotating pipe, a first air bag arranged in the rotating pipe, an air supplying mechanism used for supplying air to the first air bag, a second motor slidably installed in the installing drum and a cutting disc which is in transmission connection with an output shaft of the second motor; an output shaft of the first motor, the rotating drum and the installing drum are coaxially arranged; the sleeves and the installing drum are arranged in parallel; the first air bag is shaped like a cylinder and provided with a channel used for allowing a steel pipeto penetrate; and sleeves are connected to the rack. According to the steel pipe cutting machine, rotating fit between the rotating pipe and the sleeves is skillfully utilized, rotation of the friction assemblies (particularly, friction layers) on the steel pipe is combined, therefore, the steel pipe needing to be cut can rotate, the steel pipe is cut in the rotating process, uniform cutting canbe conducted, the cutting quality is improved, and meanwhile the cutting disc can be better protected.

Owner:HUAQIAO UNIVERSITY

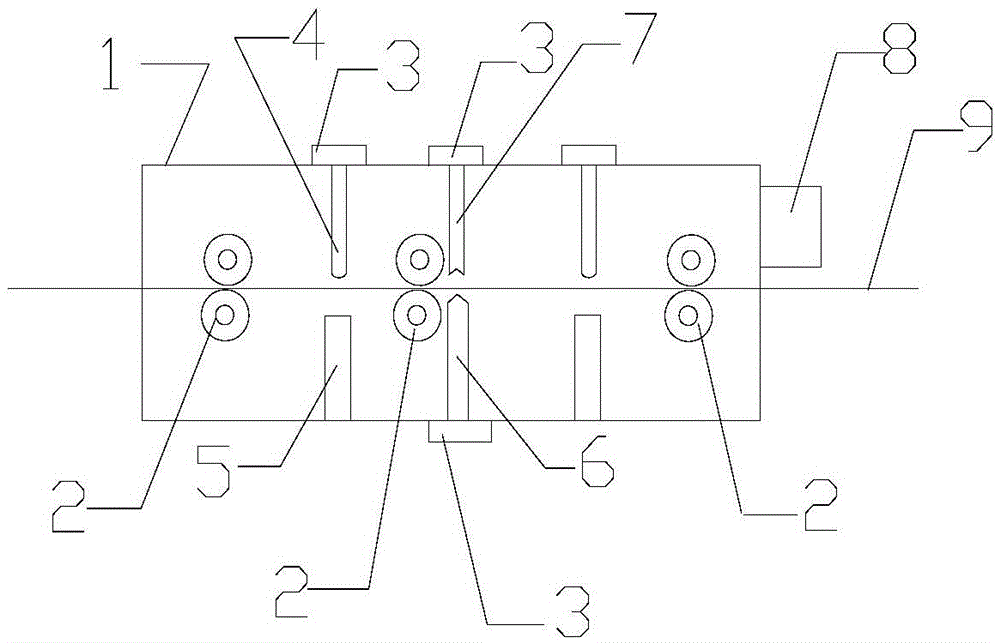

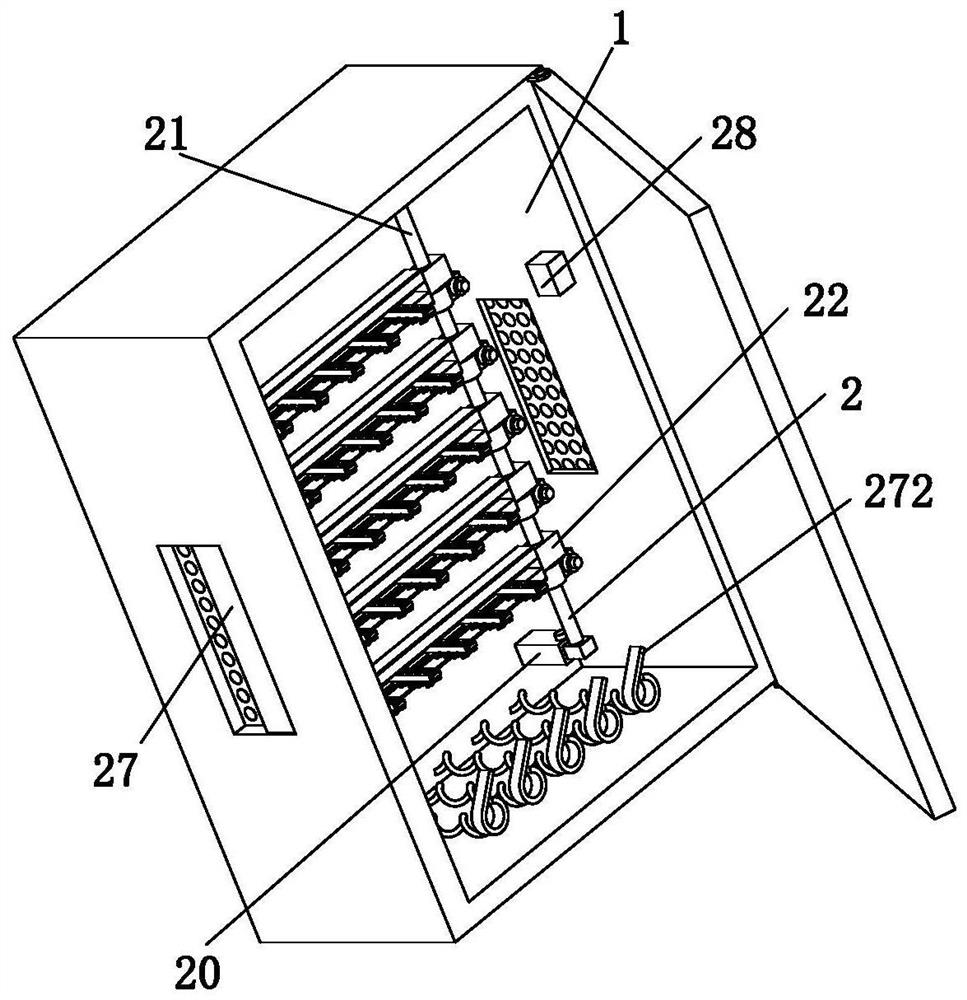

Cable cutoff device

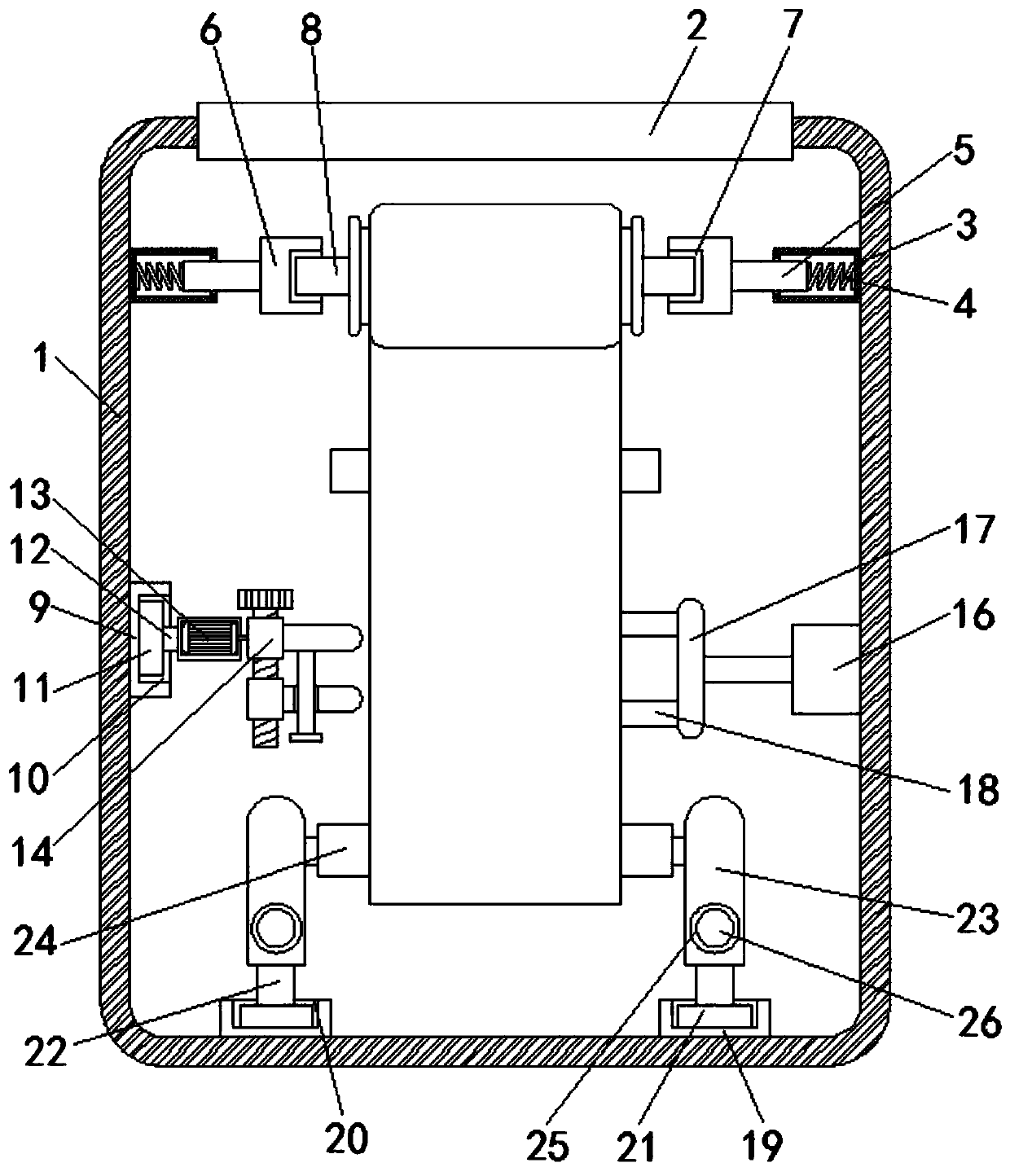

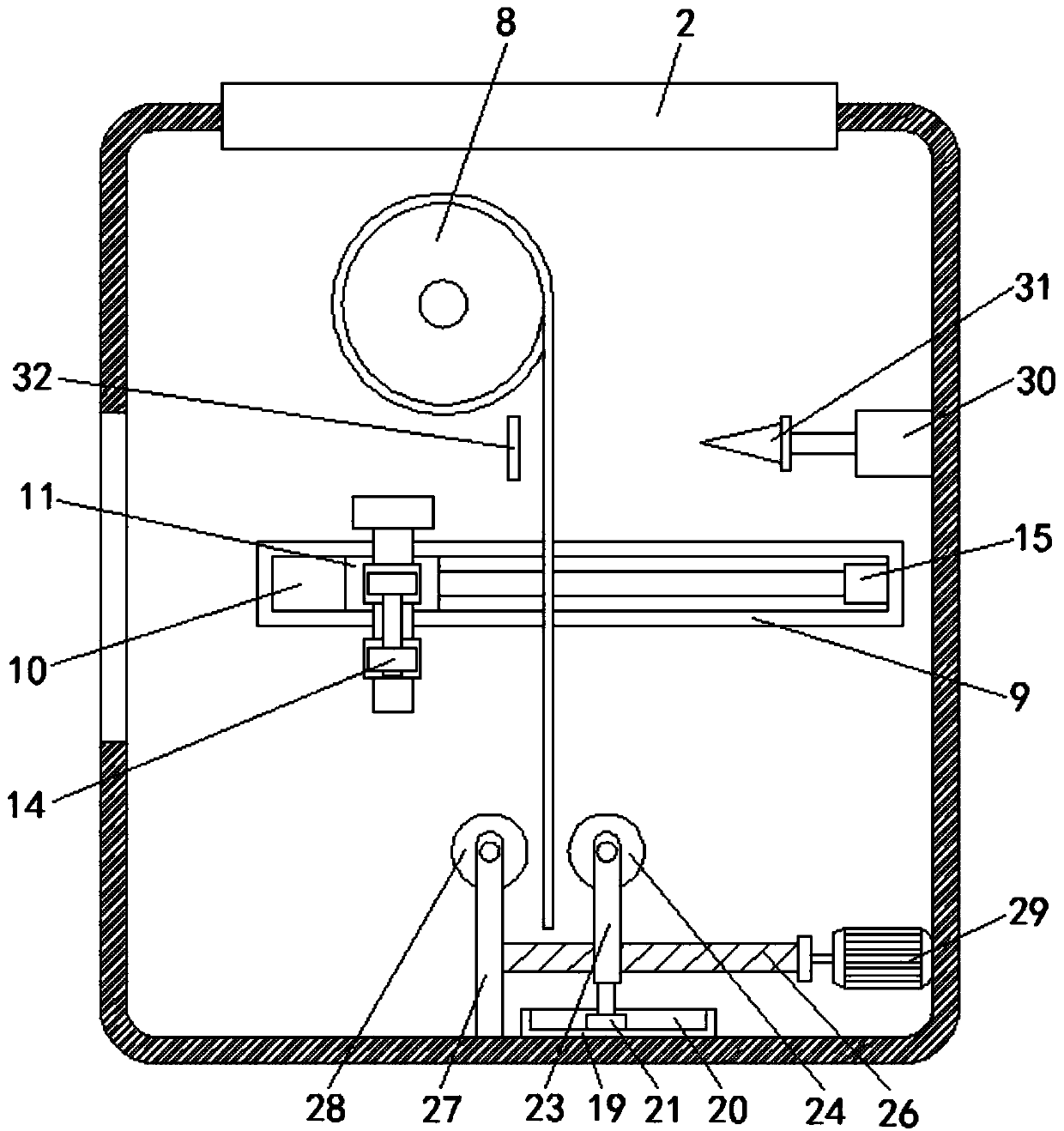

The invention discloses a cable cutoff device which comprises a box body provided with an inner cavity. A cutoff mechanism, multiple sets of clamping rollers and two fastening mechanisms are arranged in the inner cavity. The two fastening mechanisms are located on the two sides of the cutoff mechanism. A cooling mechanism is arranged outside the box body to lower the temperature in the inner cavity. The cutoff mechanism comprises an upper cutoff seat located at the top of the inner cavity and a lower cutoff seat located at the bottom of the inner cavity. Each fastening mechanism comprises an upper fastening seat located at the top of the inner cavity and a lower fastening seat located at the bottom of the inner cavity. The upper cutoff seat, the lower cutoff seat and the upper fastening seats are connected with drive units to be correspondingly driven to move back and face. The clamping rollers can clamp a cable and the cable can be located between the upper cutoff seat and the lower cutoff seat and between the upper fastening seats and the lower fastening seats. The cable which is cut off through the cable cutoff device has the excellent cutoff face.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

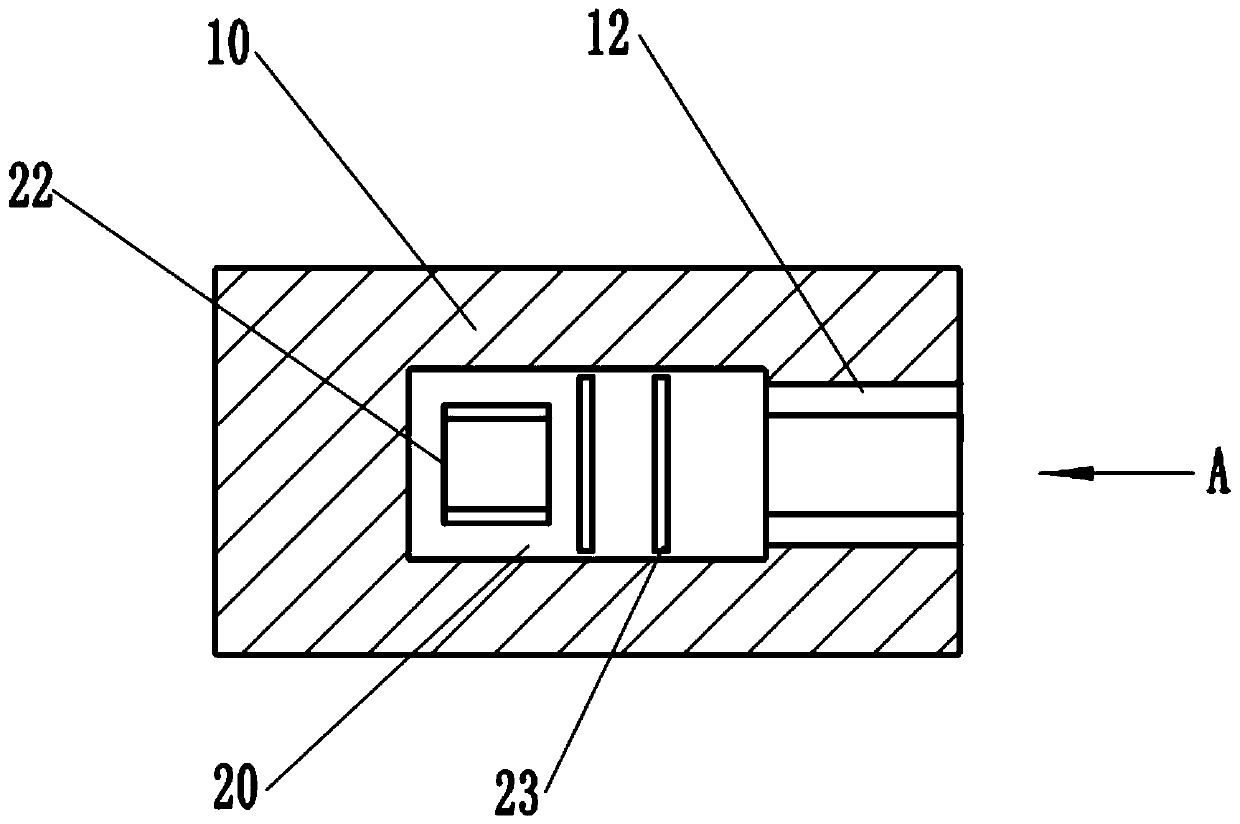

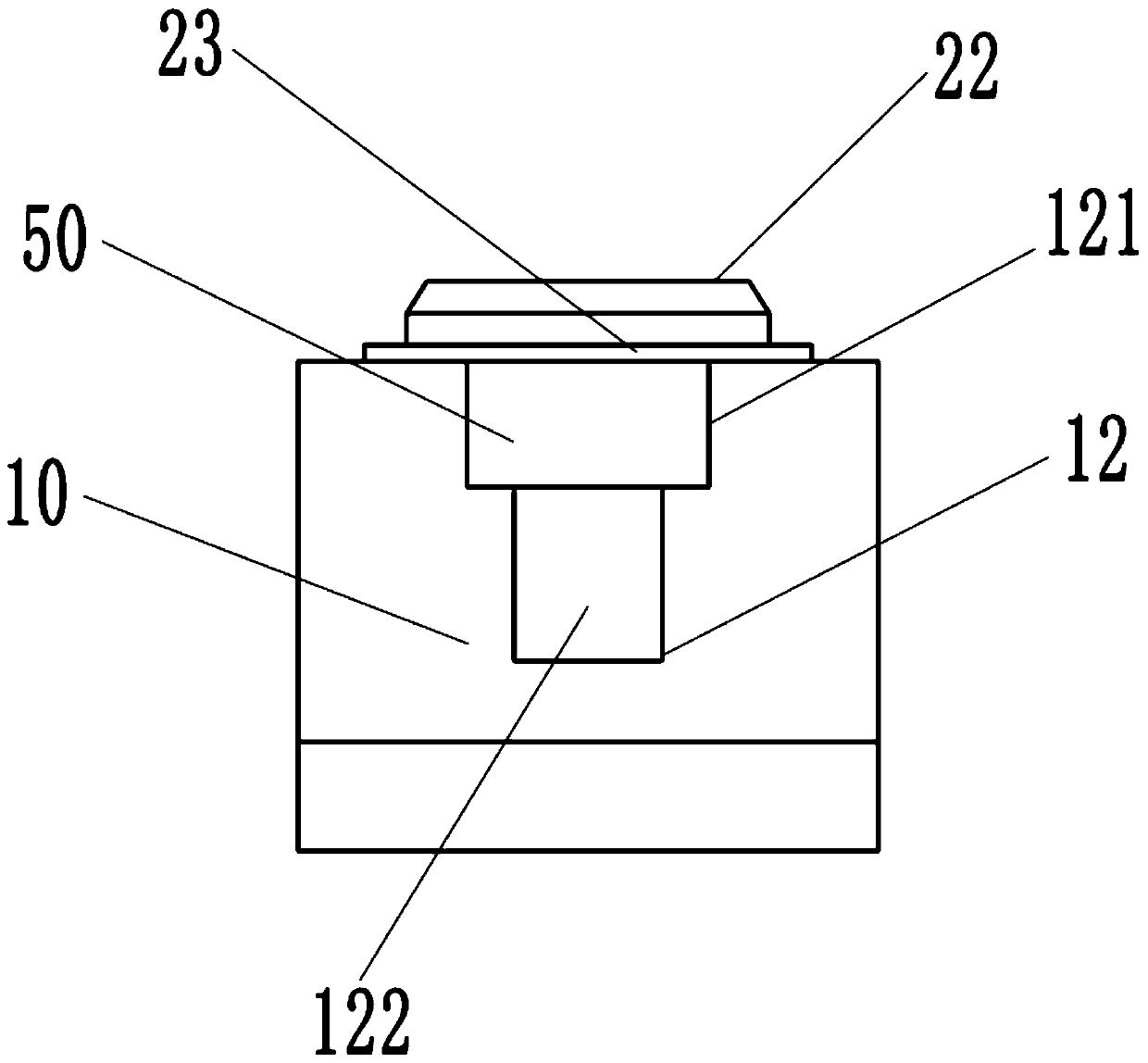

Connecting piece embedding device and method

The invention provides a connecting piece embedding device and method. The connecting piece embedding device comprises a base, a feeding unit, a pressing unit, a slide platform and a fixing press block, wherein the slide platform is arranged on the base, and the fixing press block is arranged above the slide platform. By means of the technical scheme, a pushing device provided by the invention has the benefits as follows: firstly, two push plates are provided and mainly used for clamping a connecting piece, and the dislocation problem of connecting piece turning and upwarping and the like are thoroughly solved; secondly, the push plates can be freely replaced according to the thickness of the connecting piece, and the application range is wider; and thirdly, empty pressing and mistaken pressing under the shortage condition are effectively prevented by means of concave and convex plates.

Owner:深圳市华胜数控科技有限公司

Integrated stormy-wave-proof ecological floating ball used for water ecological restoration

ActiveCN113575404AAvoid nibblingAvoid deathTreatment using aerobic processesSustainable biological treatmentMicroorganismWind wave

The invention discloses an integrated stormy-wave-proof ecological floating ball used for water ecological restoration. The integrated stormy-wave-proof ecological floating ball comprises a floating ball body, a fixing device, a wave-proof device, a microbial purification device and an aeration device, wherein the fixing device comprises a clamping and fixing mechanism and a fixing pipe; the top of the fixing pipe penetrates through the top of the inner wall of the floating ball body; and in addition, after the top of the fixing pipe extends out of the top of the floating ball body, the top of the fixing pipe is in threaded connection with the clamping and fixing mechanism; the bottom of the fixing pipe penetrates through the bottom of the floating ball body; after the fixing pipe extends out of the bottom of the floating ball body, the fixing pipe communicates with a balance weight ball body; the outer wall of a sponge cover is fixedly connected with the inner wall of the fixing pipe; a spherical cavity is arranged in the balance weight ball; a plurality of root system holes are arranged on the inner wall of the spherical cavity and communicate with an external water body; the wave-proof device is in sleeving to the outer wall of the floating ball body; the microbial purification device is in sleeving to the bottom of the outer wall of the fixing pipe; the top of the microbial purification device is fixedly connected with the bottom surface of the floating ball body; the aeration device is arranged at the bottom of the inner cavity of the floating ball body; and the aeration device is in sleeving to the outer wall of the fixing pipe.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Device for automatically coating parts with packaging films

InactiveCN110871916AEasy to wrapEasy to useWrapping with article rotationEngineeringStructural engineering

The invention relates to the technical field of processing of parts and discloses a device for automatically coating parts with packaging films. The device comprises a main body box, wherein the top of the main box body is articulated with a box cover; sleeves are fixedly mounted on the inner walls of the left side and the right side of the main box body; the inner walls of the two sleeves are fixedly connected with springs; opposite sides of the two springs are fixedly connected with movable rods; opposite sides of the two movable rods are fixedly connected with clamping blocks; clamping grooves are formed in opposite sides of the two clamping blocks; a winding roller is movably connected between the two clamping grooves; the inner wall of the left side of the main box body is fixedly connected with a fixed block; a first sliding groove is formed in the right side of the fixed block; the inside of the first sliding groove is movably connected with a first sliding block; the right sideof the first sliding block is fixedly connected with a first sliding rod. The device for automatically coating parts with packaging films is convenient to use and simple to operate; and the operatingefficiency is greatly improved.

Owner:江苏凯艾斯汽车配件有限公司

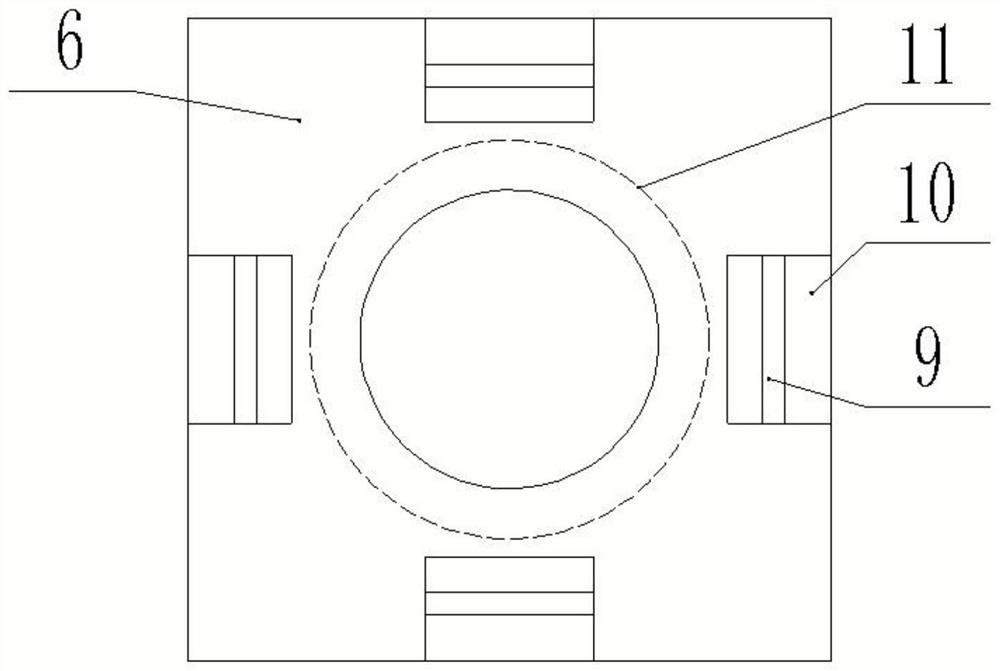

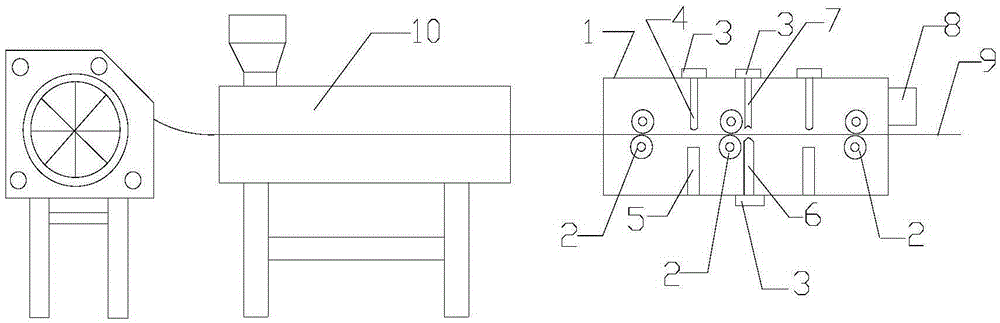

Cylindrical graphite machining method and machining device

ActiveCN108340471APlay the role of clampingRealize full demouldingCeramic shaping plantsElectrical resistance and conductanceGraphite electrode

The invention relates to a cylindrical graphite machining method and machining device, and belongs to the technical field of graphite electrodes. The cylindrical graphite machining method and machining device aims to solve the problems that a traditional graphite electrode is poor in conductivity and a compression die is not suitable for production of a novel graphite electrode. The machining device is characterized in that a base is fixed on an operation table of a press machine, a female die fixing seat is fixedly arranged on the base, and a female die is inlaid in the upper end surface of the female die fixing seat; the female die fixing seat and the female die are connected through a threaded rod, the female die is of an inverted circular truncated cone shape, and a through hole is formed in the center of the female die; a female die sleeve is arranged in the through hole, and a second through hole is formed in the bottom end of the female die sleeve; an annular resistance wire isarranged in a body of the female die, and the annular resistance wire surrounds the inner wall of the through hole; and a connecting plate is arranged on the output end of the press machine and is located above the female die, a male die assembly is arranged on the lower end face of the connecting plate, and the male die assembly and the female die are oppositely arranged. According to the cylindrical graphite machining method and machining device, the production cost of the graphite electrode can be reduced, and meanwhile, conductivity of the electrode can be improved.

Owner:黑龙江澳星能源科技有限公司

Cable Cutting Device

The invention discloses a cable cutting device, which comprises a box body with an inner cavity. The inner cavity is provided with a cutting mechanism, multiple sets of clamping rollers and two fastening mechanisms. The two fastening mechanisms are located on both sides of the cutting mechanism. A cooling mechanism is provided outside the box to reduce the temperature in the inner cavity; the cut-off mechanism includes an upper cut-off seat at the top of the inner cavity and an upper cut-off seat at the bottom of the inner cavity, and the fastening mechanism includes a fastening upper seat at the top of the inner cavity and an upper cut-off seat at the inner cavity The fastening lower seat on the bottom of the cavity, the upper cut-off seat, the lower cut-off seat and the fastening upper seat are all connected with a drive unit to drive the upper cut-off seat, the lower cut-off seat and the fastening upper seat to and fro; wherein, the clamping roller can clamp Tighten the cable, and the cable can be located between the upper cut-off seat and the lower cut-off seat and between the fastening upper seat and the fastening lower seat. The cable cut by the cable cutting device has an excellent cut surface.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Edge cutting equipment for glass fiber cloth production and edge cutting process thereof

InactiveCN114517402AEasy to pass throughImprove trimming effectTextile selvedgesSevering textilesGlass fiberEngineering

The invention belongs to the technical field of glass fiber cloth production, particularly relates to edge cutting equipment for glass fiber cloth production and an edge cutting process thereof, and provides the following scheme that the edge cutting equipment comprises a workbench and an edge cutter, supporting frames are fixedly connected to the outer walls of the two sides of the workbench, and fixing plates are fixedly connected to the outer walls of the opposite sides of the two supporting frames; the outer walls of the opposite sides of the two fixing plates are fixedly connected with two third connecting shafts and two second connecting shafts through bearings. By arranging the secondary edge cutting assembly, after edge cutting operation is conducted on glass fiber cloth through an edge cutter, the strength of the glass fiber cloth is high, and burrs still exist after single-time edge cutting, at the moment, a second air cylinder is adjusted to drive a sliding block to slide in a guide rail, so that the glass fiber cloth is subjected to edge cutting operation; therefore, the secondary trimming cutter is driven to perform secondary trimming operation on the trimming position of the glass fiber cloth, complete cutting of the trimming position of the glass fiber cloth is ensured, and the trimming effect of the glass fiber cloth is further improved.

Owner:JIANGSU JIACHENG SPECIAL FIBER

Multi-shape clamping device for aluminum-plastic equipment

InactiveCN112355689AAchieve the effect of clamping multiple shapesReduce manufacturing costPositioning apparatusMetal-working holdersDielectric platePlastic materials

The invention discloses a multi-shape clamping device for aluminum-plastic equipment and relates to the technical field of aluminum-plastic equipment. The multi-shape clamping device for the aluminum-plastic equipment comprises a clamping plate, an electromagnet is fixedly connected to the inner wall of the clamping plate, a clamping groove is formed in the inner wall of the clamping plate, and aspring is fixedly connected to the position, close to the right side of the electromagnet, of the inner wall of the clamping plate; and the right side of the spring is fixedly connected with a pistonblock, the left side of the piston block is fixedly connected with a magnetic block, the middle of the piston block is fixedly connected with a dielectric plate, and the right side of the piston blockis fixedly connected with electric conduction blocks. According to the multi-shape clamping device for the aluminum-plastic equipment, through cooperative use of the clamping groove and a rubber film, when a clamp clamps objects in different shapes, the rubber film can change according to the shapes of aluminum-plastic materials, electrorheological fluid in the clamping groove is extruded, and when the electrorheological fluid is extruded to a certain degree, the electrorheological fluid can become into a solid state under the electrification effect, the clamped shapes are effectively fixed,and therefore the effect of being capable of clamping multiple shapes is achieved, the production cost is saved, and the production efficiency is effectively improved.

Owner:温州嘉创电子商务秘书有限公司

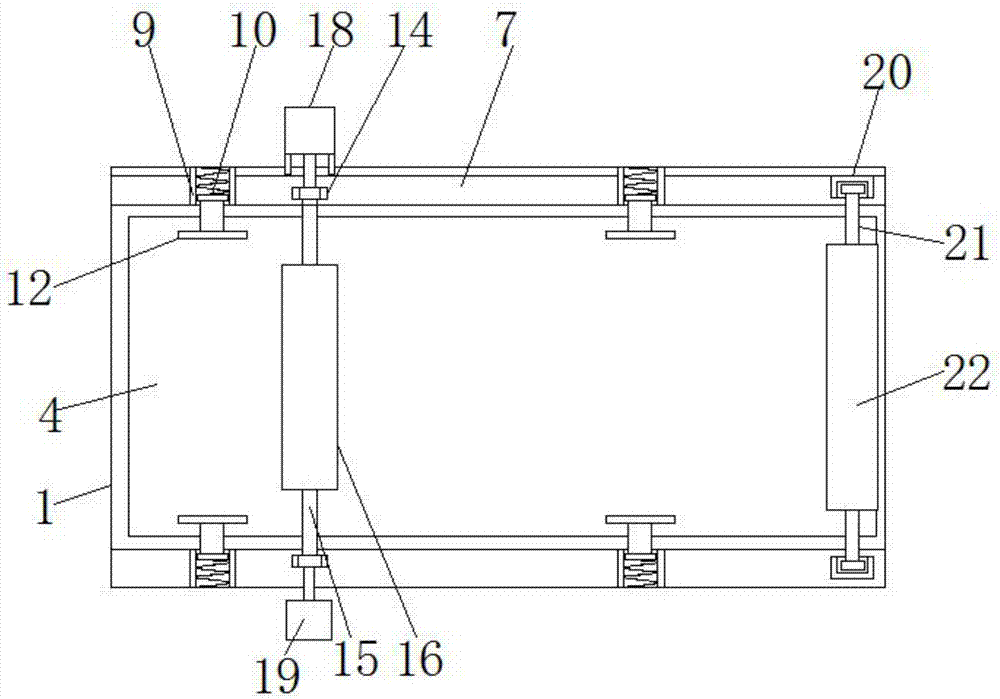

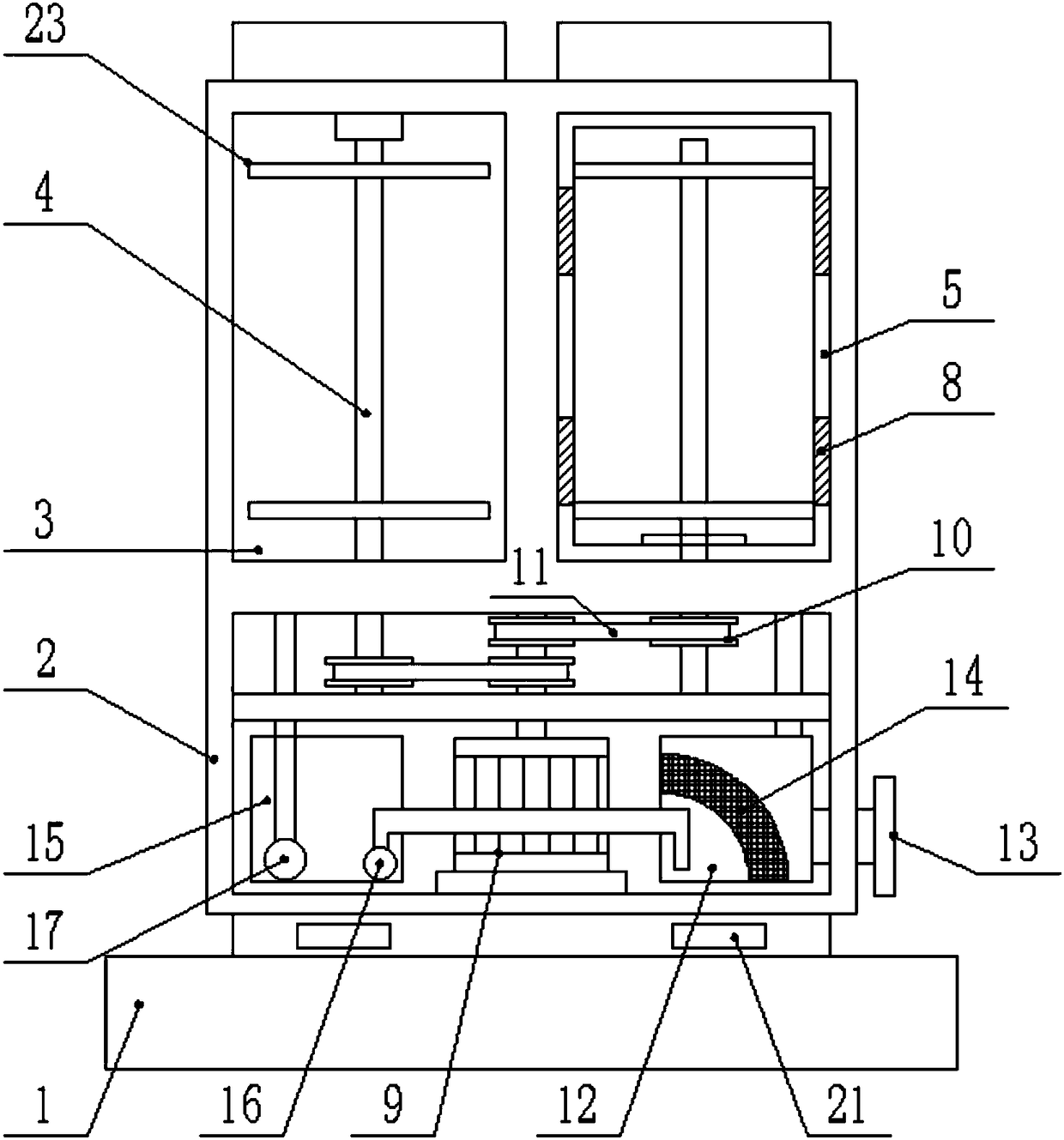

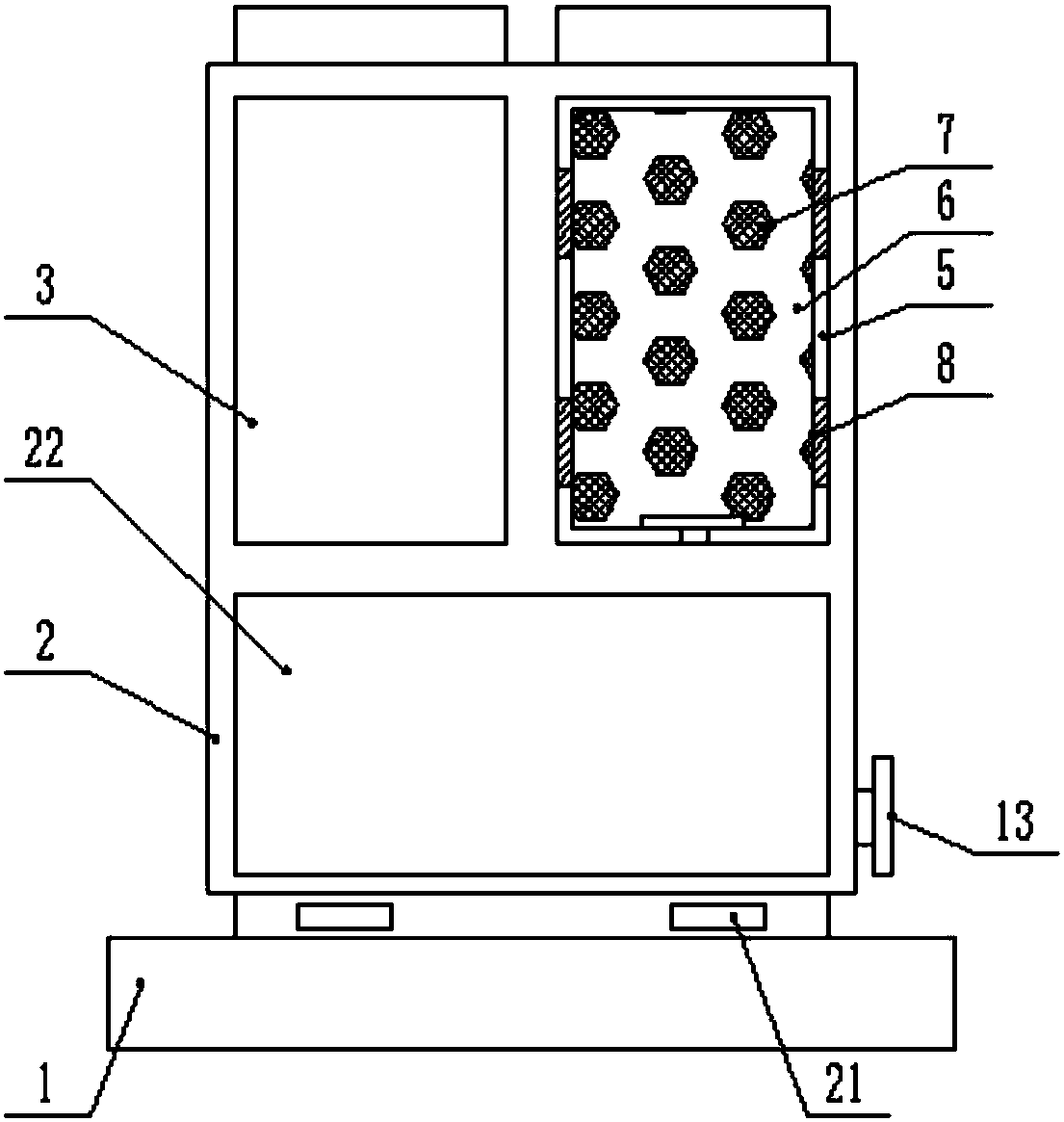

Electric power high-low voltage switch cabinet

InactiveCN113328356AImprove stabilityImprove uniformityBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationMechanical engineeringControl theory

The invention relates to an electric power high-low voltage switch cabinet. The switch cabinet comprises a cabinet body and an installation mechanism, the cabinet body is placed on the existing ground, and the installation mechanism is arranged in the cabinet body.According to the invention, the design concept of combined regulation and control is used for the power high-low voltage switch cabinet, the installation mechanism can carry out corresponding clamping installation on electrical components with different heights and sizes, the installation positions of the electrical components in the cabinet body can be adjusted according to use requirements, and meanwhile, a heat dissipation structure is arranged in the installation mechanism to cool the interior of the cabinet body in time, so the phenomenon that electric appliance elements are damaged due to long-time accumulation of working heat can be effectively avoided.

Owner:JIANGSU ZHONGMENG ELECTRIC EQUIP

Cable continuous processing system

InactiveCN105427959AExcellent cross sectionPlay the role of clampingCable/conductor manufactureMolding machineEngineering

The invention discloses a cable continuous processing system. The system comprises an extrusion forming machine and a cutting apparatus. The cutting apparatus comprises a casing with an inner cavity, the inner cavity is internally provided with a cutting mechanism, multiple groups of clamping rollers and two fastening mechanisms, the two fastening mechanisms are disposed at the two sides of the cutting mechanism, and the casing is externally provided with a cooling mechanism for reducing the temperature in the inner cavity; the cutting mechanism comprises an upper cutting seat disposed at the top of the inner cavity and a lower cutting seat at the bottom of the inner cavity, each fastening mechanism comprises a fastening upper seat disposed at the top of the inner cavity and a fastening lower seat disposed at the bottom of the inner cavity, the upper cutting seat, the lower cutting seat and the fastening upper seats are each connected with a driving unit so as to drive the upper cutting seat, the lower cutting seats and the fastening upper seats to perform reciprocating movement; and the clamping rollers can clamp a cable processed by the extrusion forming machine, and the cable can be disposed between the upper cutting seat and the lower cutting seat and between the fastening upper seats and the fastening lower seats. The cable cut through the cable continuous processing system has an excellent cut section.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

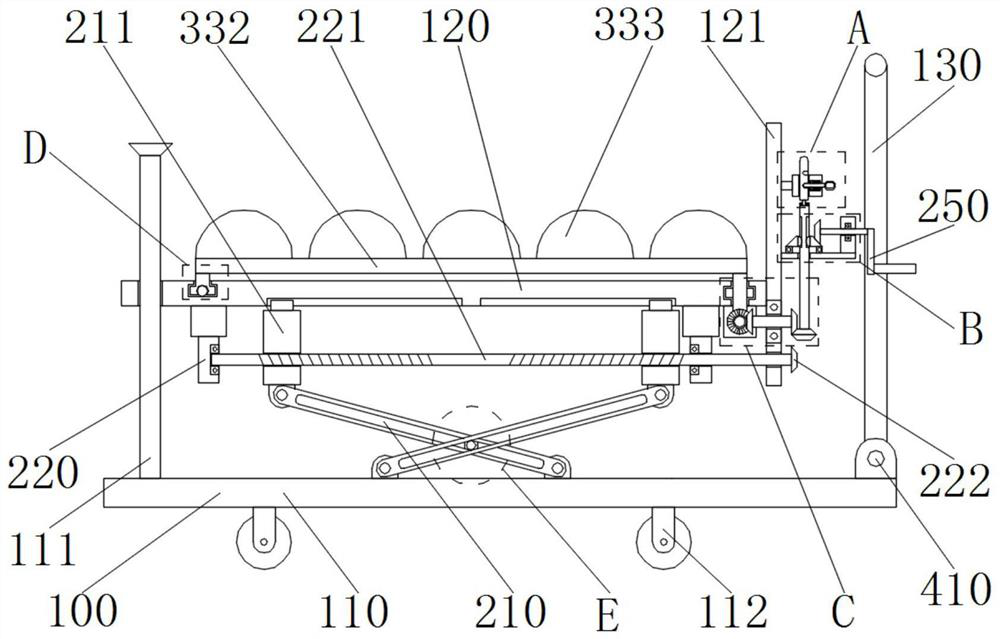

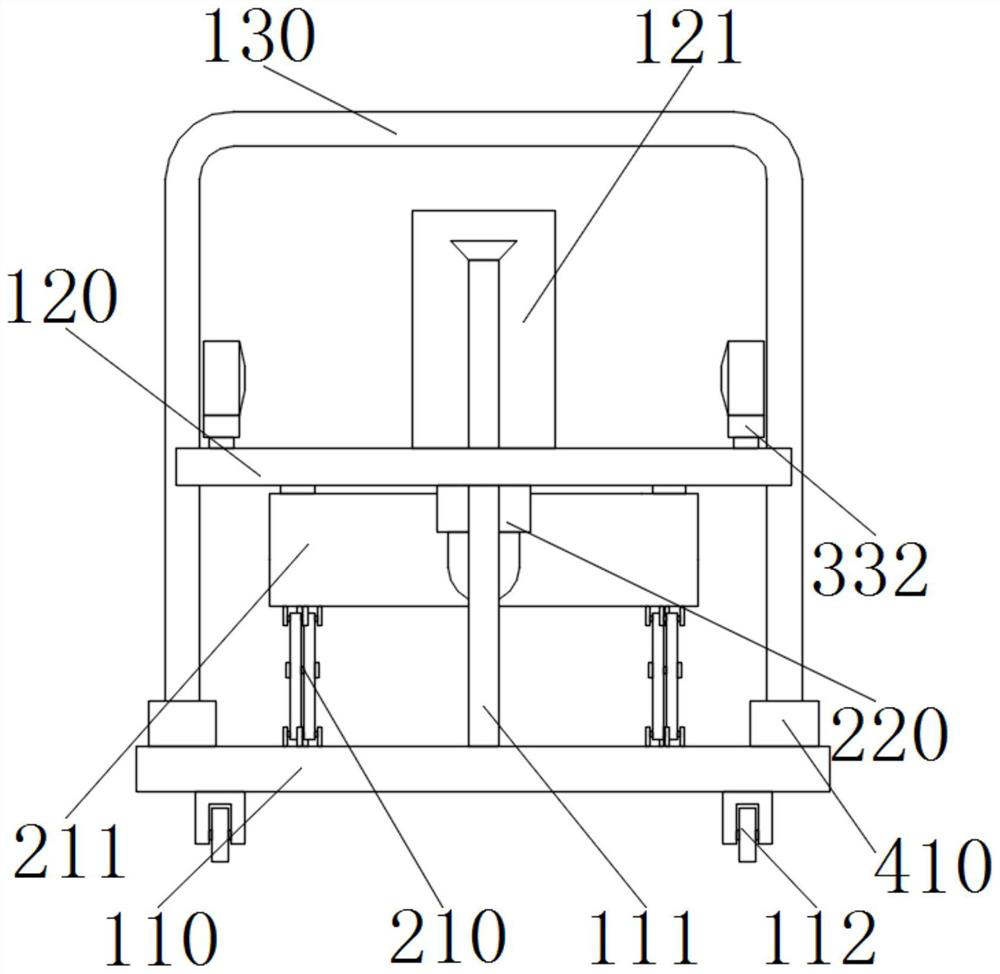

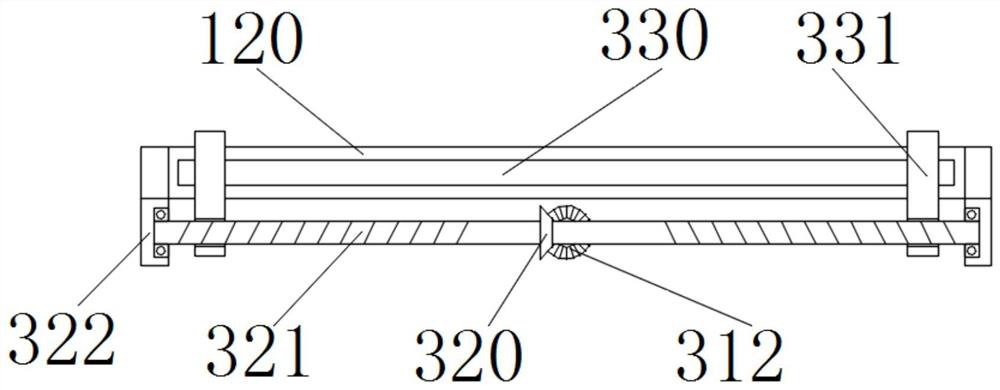

Logistics cart with convenient and rapid transfer function for logistics supply

InactiveCN112477948AEasy to transportIncrease heightSupporting partsHand carts with multiple axesLogistics managementControl theory

The invention relates to the technical field of logistics transfer transportation appliances, in particular to a logistics cart with convenient and rapid transfer function for logistics supply. The cart comprises a device main body, the device main body comprises a device base and moving wheels, the bottom end of the device base is fixedly connected with the moving wheels, and the top end of the device base is provided with a height adjusting mechanism; an objective table is fixedly connected to the top end of the height adjusting mechanism, a clamping mechanism is arranged at the top end of the objective table, a fixing plate is fixedly connected to one side of the objective table, an adjusting mechanism is fixedly connected to the side, away from the objective table, of the fixing plate,and a transmission mechanism is rotatably connected to the bottom end of the adjusting mechanism; and one side of the transmission mechanism is fixedly connected with the fixing plate, and the side,close to the objective table, of the top end of the device base is fixedly connected with a rotating shaft mechanism. In the using process, the height is convenient to adjust, and loaded goods can beclamped and fixed.

Owner:饶张福

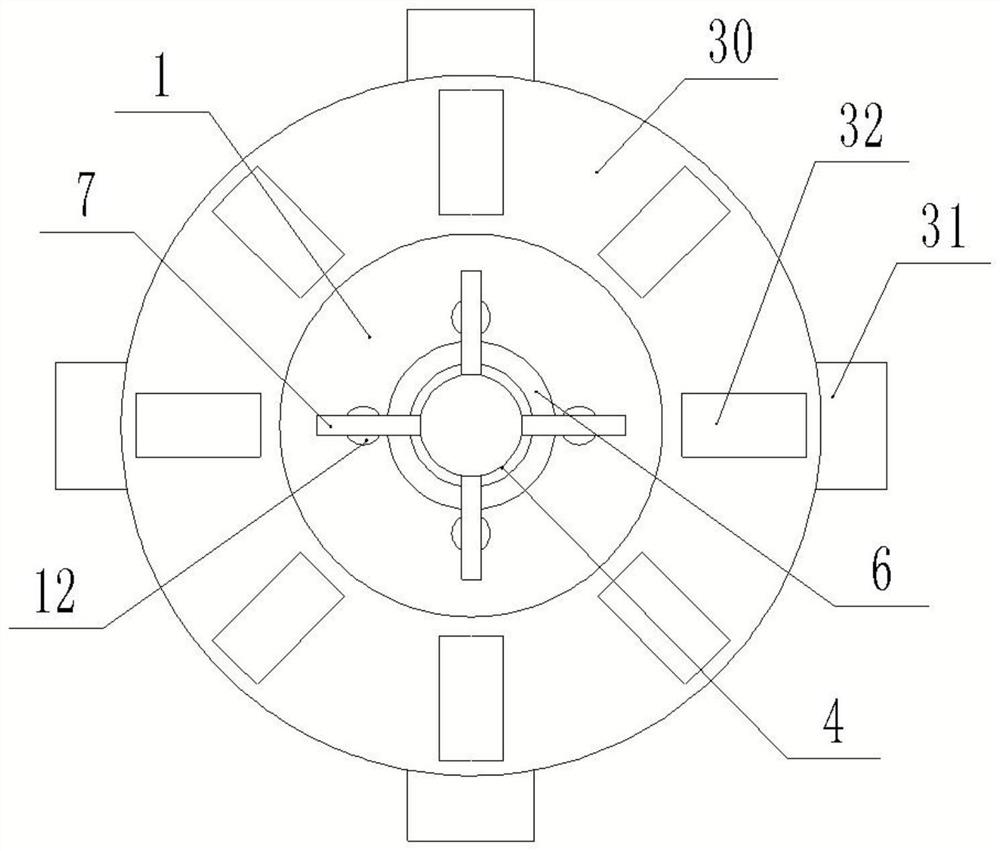

Rod-shaped traditional Chinese medicine centrifugal cleaning device

InactiveCN108405465ASimple structurePlay the role of clampingTreatment involving filtrationCleaning using liquidsBiochemical engineeringWater resources

The invention discloses a rod-shaped traditional Chinese medicine centrifugal cleaning device which comprises a device body. The device body is provided with a base; a cleaning cavity is formed in theupper portion of the base and internally provided with a first cleaning camber and a second cleaning chamber; a clamping mechanism is arranged in the first cleaning chamber, and a centrifugal cylinder is arranged in the second cleaning chamber; a rotating auxiliary mechanism is arranged on the outer wall of the centrifugal cylinder; the device body is provided with a power bin which is internallyprovided with a motor; and a filter cavity and a transition cavity are formed in the power bin. The rod-shaped traditional Chinese medicine centrifugal cleaning device is simple in structure, the clamping effect is achieved through the clamping mechanism, the centrifugal cleaning effect is achieved through the centrifugal cylinder, and under the double cleaning effect, the cleaning effect is improved; and in the cleaning process, cleaning water in the second cleaning chamber enters the filter cavity, in this way, water resources are saved, and practicability is high.

Owner:金寨县金银山农业科技开发有限公司

Long-rod-shaped workpiece clamping device

InactiveCN108188687APlay the role of clampingPlay a buffer roleMetal working apparatusScrew threadIndustrial engineering

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

A laminating device for improving laminating precision of covering film

Owner:JIANGXI KAIQIANG IND CO LTD

A processing method and processing device for cylindrical graphite

ActiveCN108340471BPlay the role of clampingRealize full demouldingCeramic shaping plantsGraphite electrodeGraphite

Owner:黑龙江澳星能源科技有限公司

Self-priming pump

InactiveCN112360754AInput and output direction changePlay the role of clampingPump componentsPriming pumpPhysicsLiquid storage

The invention relates to the technical field of self-priming pumps, in particular to a self-priming pump which comprises a bottom frame, a conveying device, a self-priming pump body, a lifting device,a cooling device, an elevating device, a rotating device, a clamping device and liquid storage devices. The conveying device is fixedly connected onto the bottom frame and communicates with the self-priming pump body; the lifting device is slidably connected with the bottom frame; the cooling device is connected with the lifting device in a sliding mode; the cooling device is matched with the conveying device; the elevating device is connected onto the bottom frame in a sliding mode; the elevating device is fixedly connected with the lifting device; the rotating device is fixedly connected onto the elevating device, and is fixedly connected with the clamping device; the self-priming pump can be clamped through the clamping device; the number of the liquid storage devices is two; the two liquid storage devices are both connected with the conveying device through pipelines; and the two liquid storage devices are both fixedly connected with the bottom frame. According to the self-primingpump provided by the invention, the input and output directions of the self-priming pump can be conveniently changed.

Owner:袁建梅

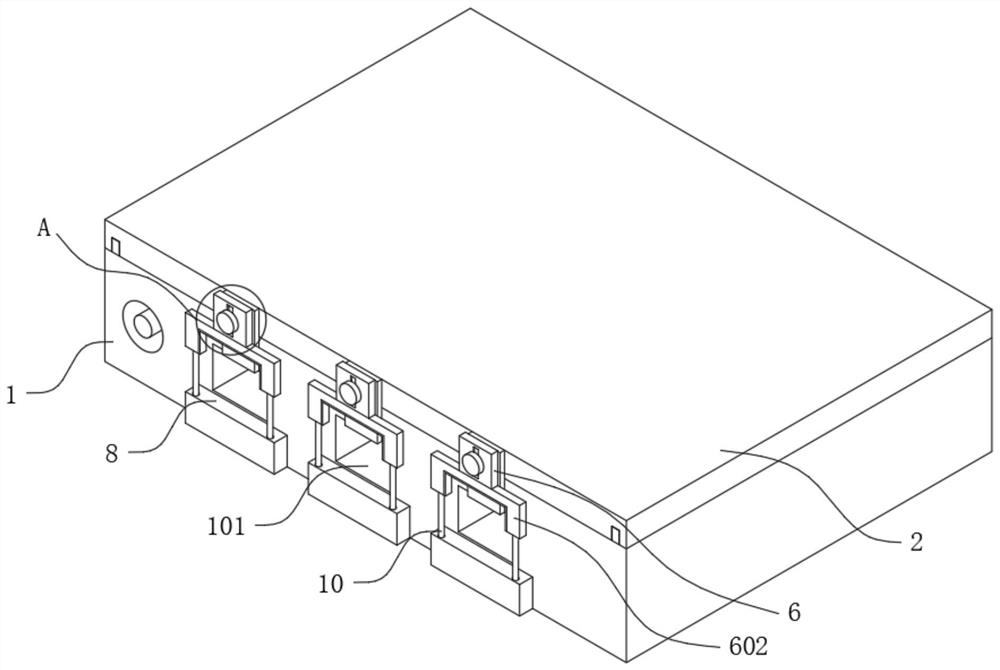

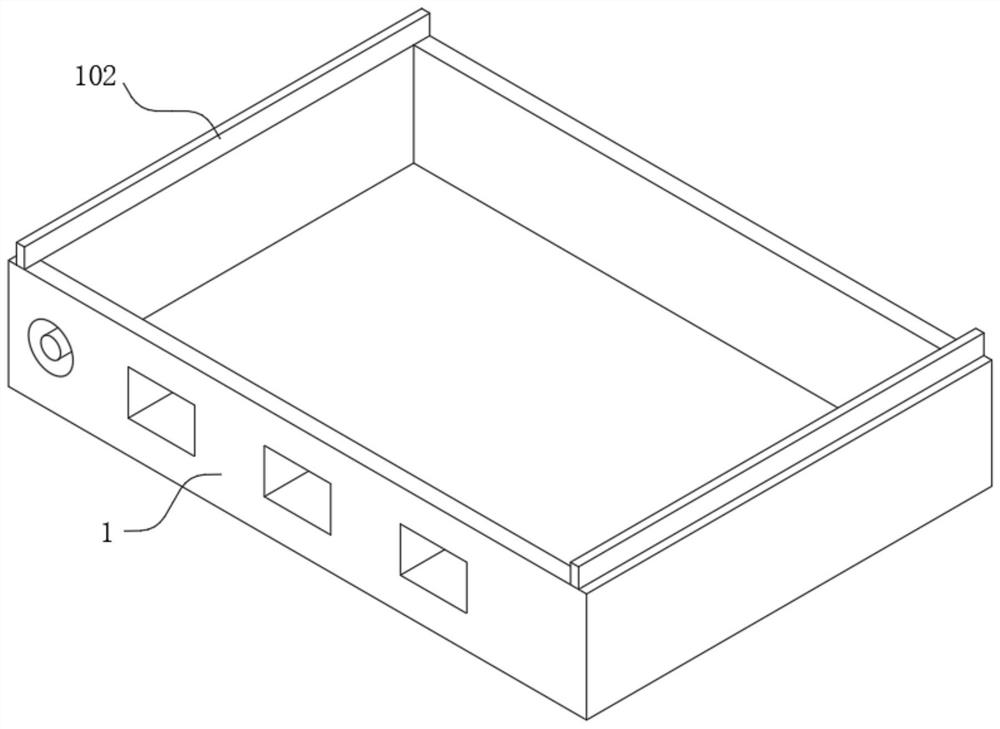

Network switch for Internet of Things signal transmission

InactiveCN113507649AEasy to disassembleReduce usageCoupling device detailsData switching networksTelecommunicationsLocking mechanism

The invention discloses a network switch for Internet of Things signal transmission, which comprises a switch body, an external connection plate, a knob, a clamping mechanism and a locking mechanism, and is characterized in that the front surface of the switch body is equidistantly provided with a plurality of switching ports, a top cover plate is assembled above the switch body, and the external connection plate is fixedly mounted on the front surface of the switch body; a movable plate is arranged on the front face of the external connection plate, the rotary knob is arranged on the front face of the movable plate, the clamping mechanism is arranged at the joint of the switch body and the top cover plate, and the locking mechanism is arranged at the joint of the external connection plate and the top cover plate. The switch has the beneficial effects that the top cover plate can be locked above the switch body by the locking mechanism through the design of the locking mechanism, so that the use of screws is avoided, an operator can conveniently disassemble the top cover plate, and the disassembly can be completed without using an external auxiliary tool; therefore, the operator can maintain the electrical components in the switch body conveniently to a great extent.

Owner:马良华

Coating-type coating equipment for optical lens preparation

ActiveCN113385360AGuaranteed balanceAvoid stickingLiquid surface applicatorsCoatingsOptic lensFilm-coated tablet

The invention discloses coating-type coating equipment for optical lens preparation. The coating-type coating equipment comprises a body, a coating liquid placing chamber, a coating mechanism, a clamping mechanism and guide mechanisms, wherein the body is mounted on the ground; the coating liquid placing chamber is mounted above the film coating chamber; the coating mechanism is mounted in the film coating chamber; the clamping mechanism is mounted above a placement frame, and a lifting mechanism is mounted in the clamping mechanism; and the guide mechanisms are mounted at two sides of the coating mechanism, and the guide mechanisms are movably connected with guide grooves. According to the coating-type film coating equipment for optical lens preparation, coating-type coating is adopted in the coating process of optical lenses, so that the coating effect is better, and the coating balance can be effectively guaranteed; meanwhile, the lenses of different sizes and thicknesses can be subjected to coating-type coating in the use process, so that the application range of the equipment is widened; and in the use process, the situation that coating cannot meet the required requirement due to the adhesion phenomenon of coating liquid can be effectively avoided.

Owner:宁波法里奥光学科技发展有限公司

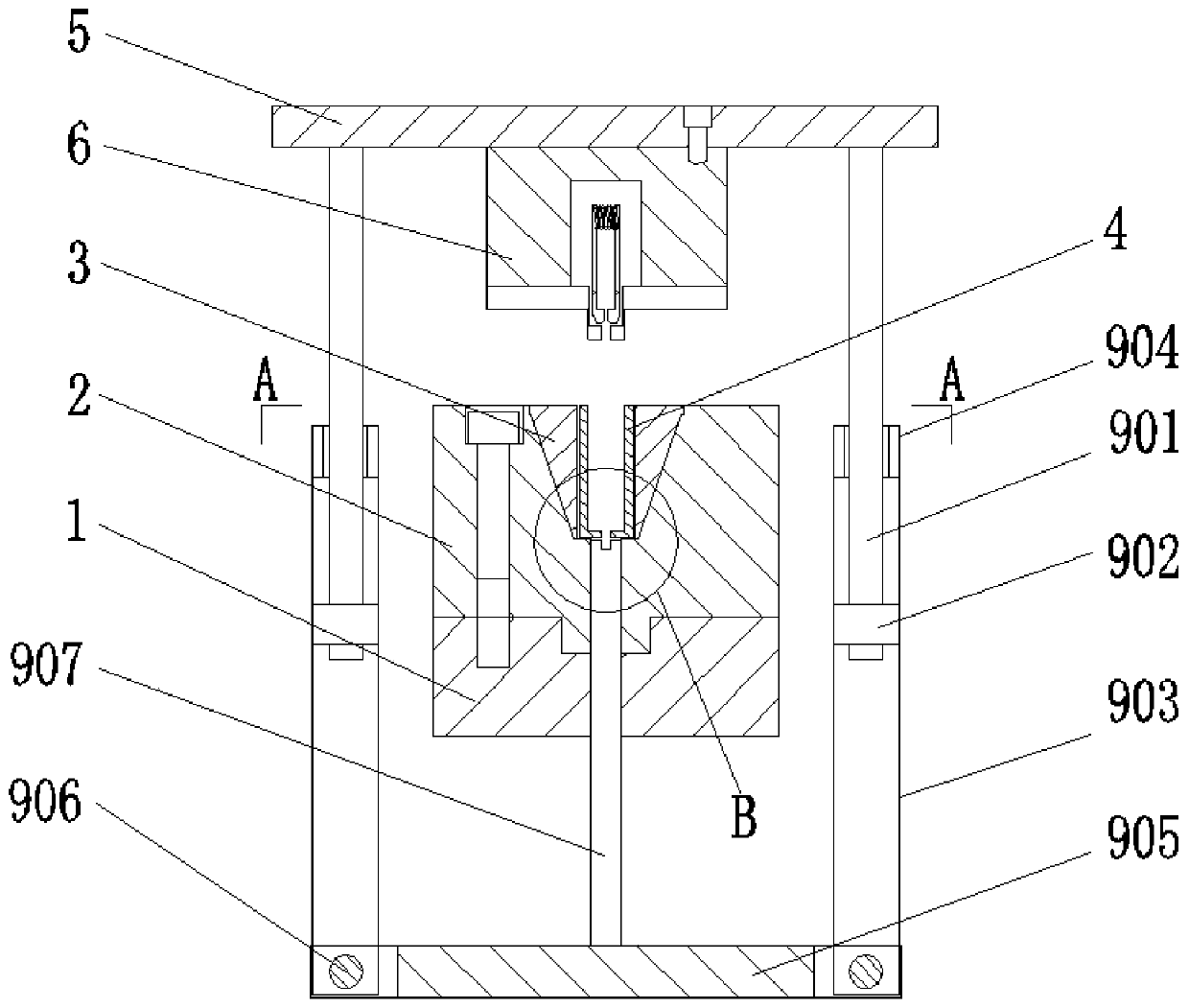

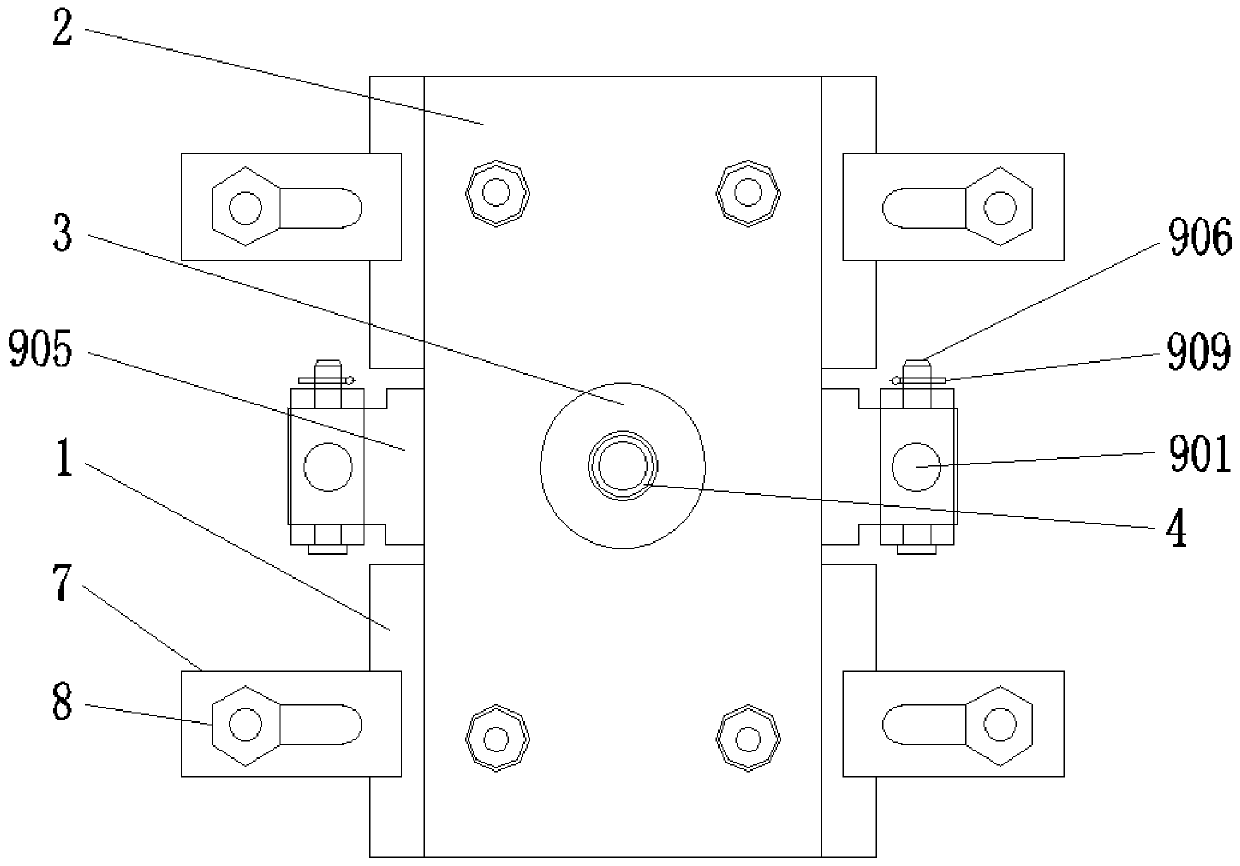

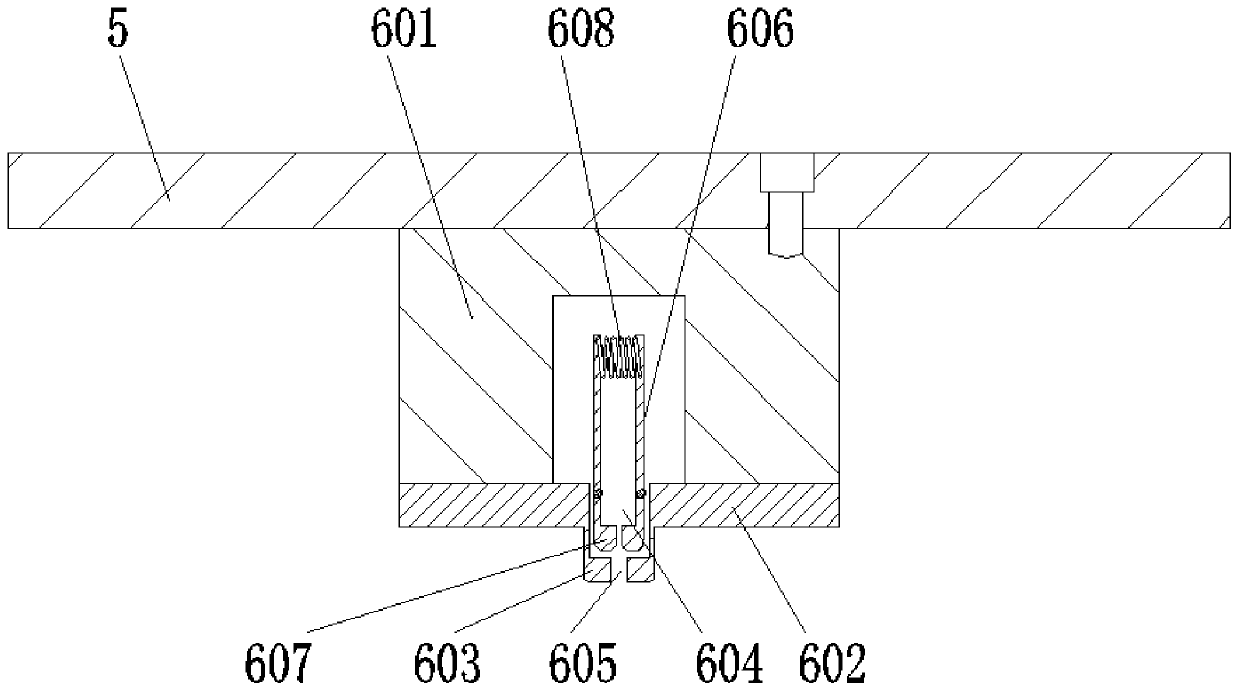

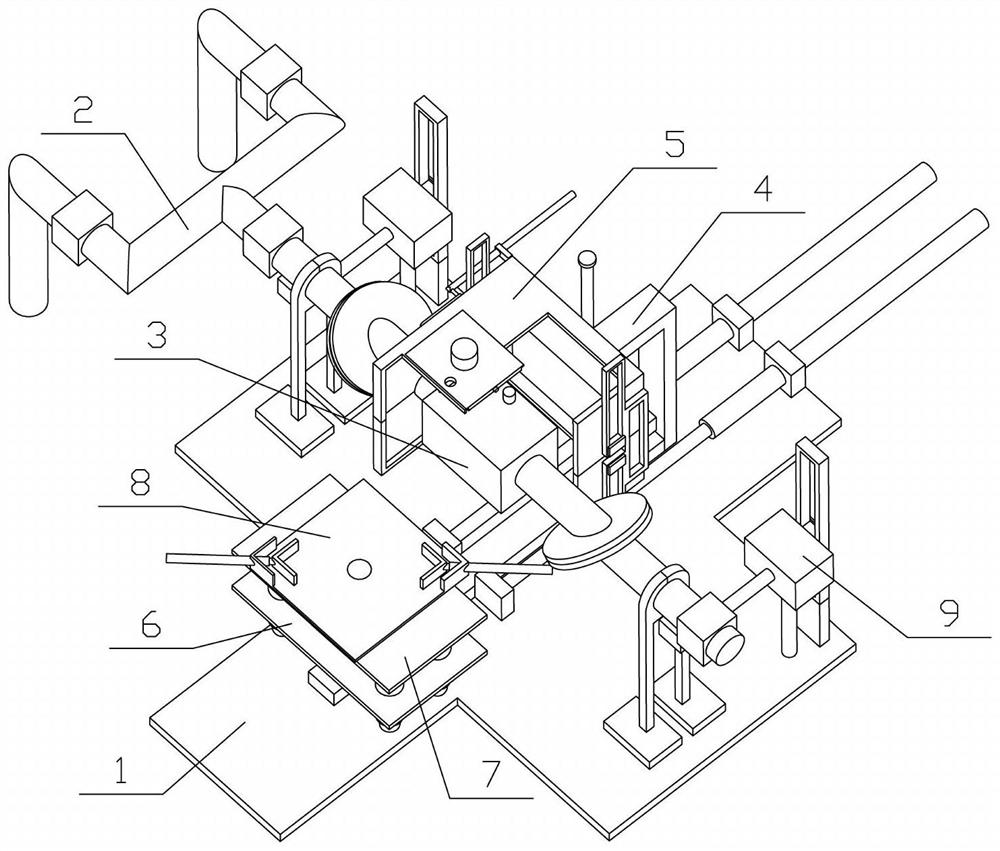

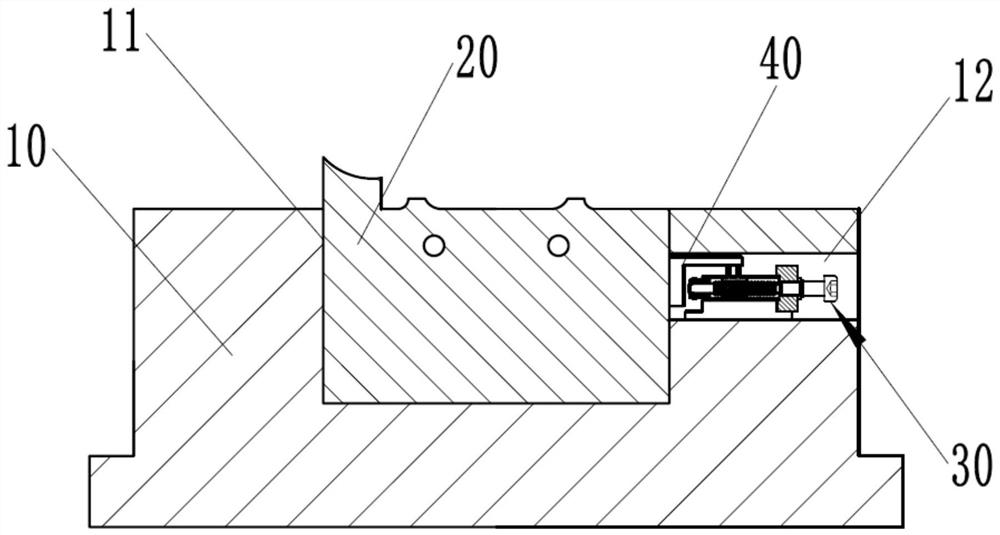

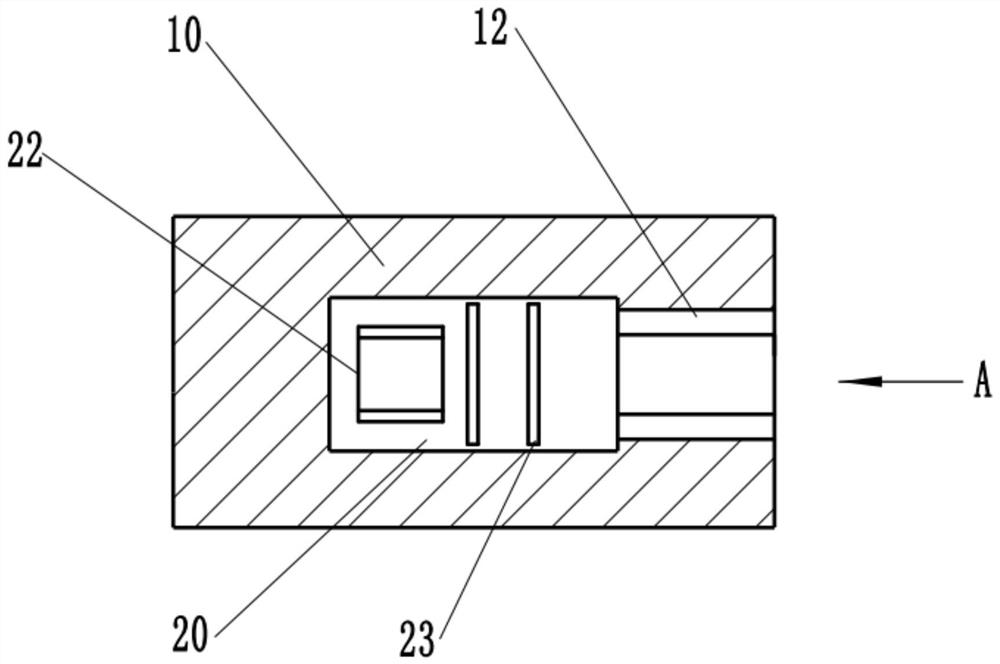

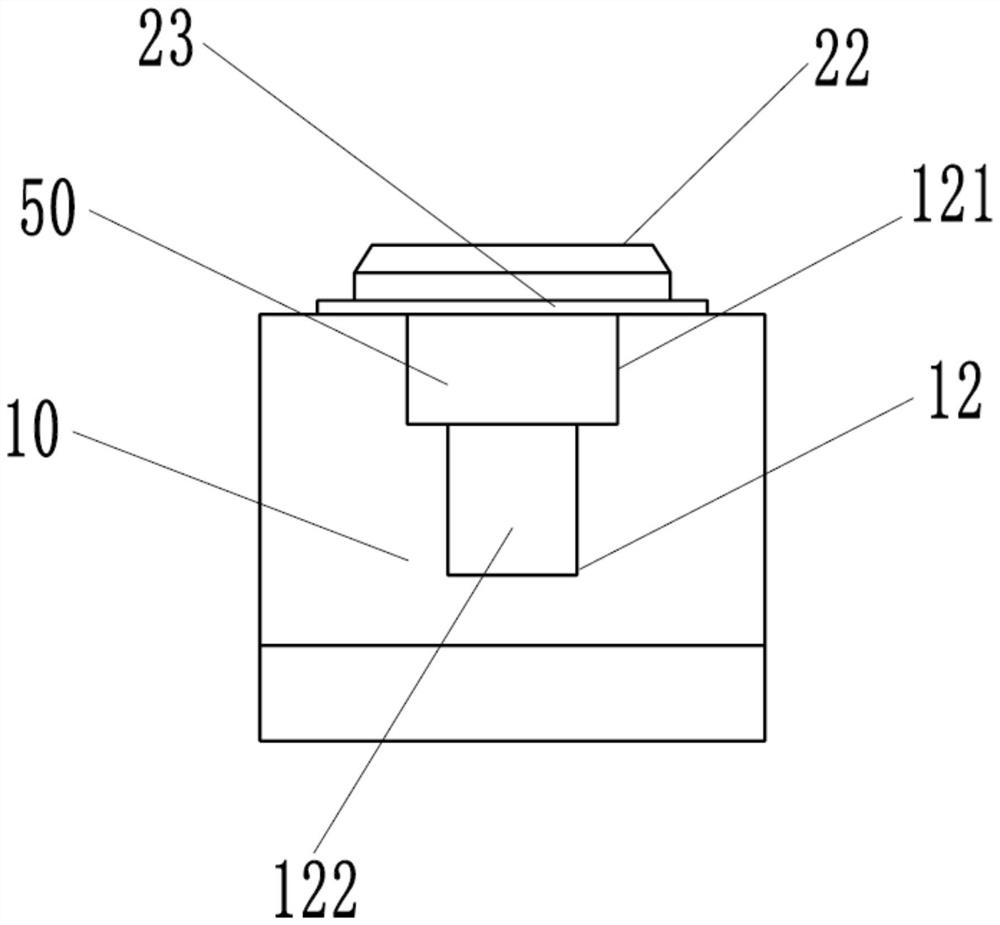

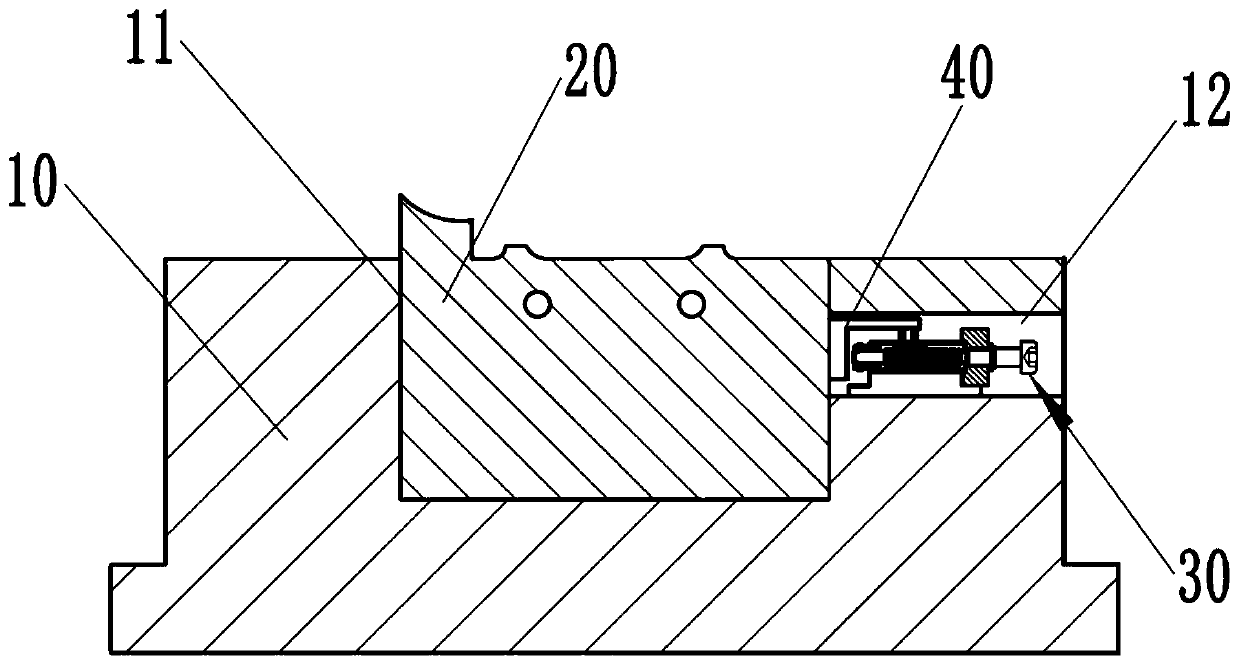

A core structure of micro-foaming injection mold

Owner:东莞市建祥模具有限公司

Mold core structure of micro-foaming injection mold

Owner:HANGZHOU POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com