Nonferrous metal product polishing device

A technology for non-ferrous metals and products. It is applied in the direction of grinding drive devices, metal processing equipment, and devices for fixing grinding wheels. It can solve the problems of inconvenient replacement of grinding tools, low clamping efficiency of workpieces, and cumbersome processes of multi-directional grinding of workpieces. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

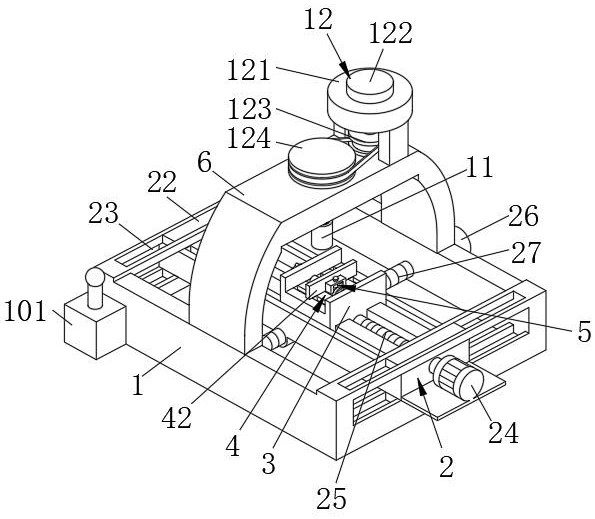

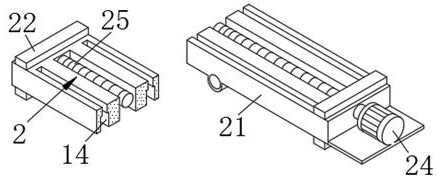

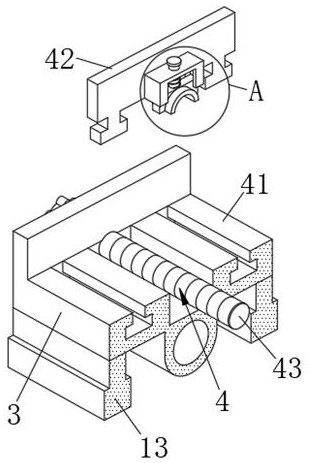

[0038] see Figure 1-7 , the present invention provides a technical solution, a non-ferrous metal product grinding device, including a processing table 1, the inner cavity of the processing table 1 is provided with an azimuth adjustment mechanism 2, and the azimuth adjustment mechanism 2 includes a sliding door that is slidably connected to the inner cavity of the processing table 1. Plate 21, the front side and the rear side of the sliding plate 21 top and the front side and the rear side of the bottom are all fixedly connected with guide sliders 22, and the front side and the rear side of the processing table 1 top are all provided with guide sliders 22. The guide chute 23 is equipped, the rear side of the sliding plate 21 is fixedly connected with a longitudinal driving motor 24, the output shaft of the longitudinal driving motor 24 penetrates into the inner cavity of the sliding plate 21 and is fixedly connected with a longitudinal driving screw 25, and the longitudinal dri...

Embodiment 2

[0041] see Figure 1-7 , the present invention provides a technical solution, a non-ferrous metal product grinding device, including a processing table 1, the inner cavity of the processing table 1 is provided with an azimuth adjustment mechanism 2, and the azimuth adjustment mechanism 2 includes a sliding door that is slidably connected to the inner cavity of the processing table 1. Plate 21, the front side and the rear side of the sliding plate 21 top and the front side and the rear side of the bottom are all fixedly connected with guide sliders 22, and the front side and the rear side of the processing table 1 top are all provided with guide sliders 22. The guide chute 23 is equipped, the rear side of the sliding plate 21 is fixedly connected with a longitudinal driving motor 24, the output shaft of the longitudinal driving motor 24 penetrates into the inner cavity of the sliding plate 21 and is fixedly connected with a longitudinal driving screw 25, and the longitudinal dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com