Steel pipe cutting machine

A technology for cutting machines and steel pipes, which is applied in the direction of pipe shearing devices, shearing devices, and attachments of shearing machines, etc., which can solve the problems of inconvenient steel pipe connection protection, inconvenient uniform cutting, and difficult steel pipe protection, so as to avoid the amount of cutting Excessive size, improved cutting quality, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

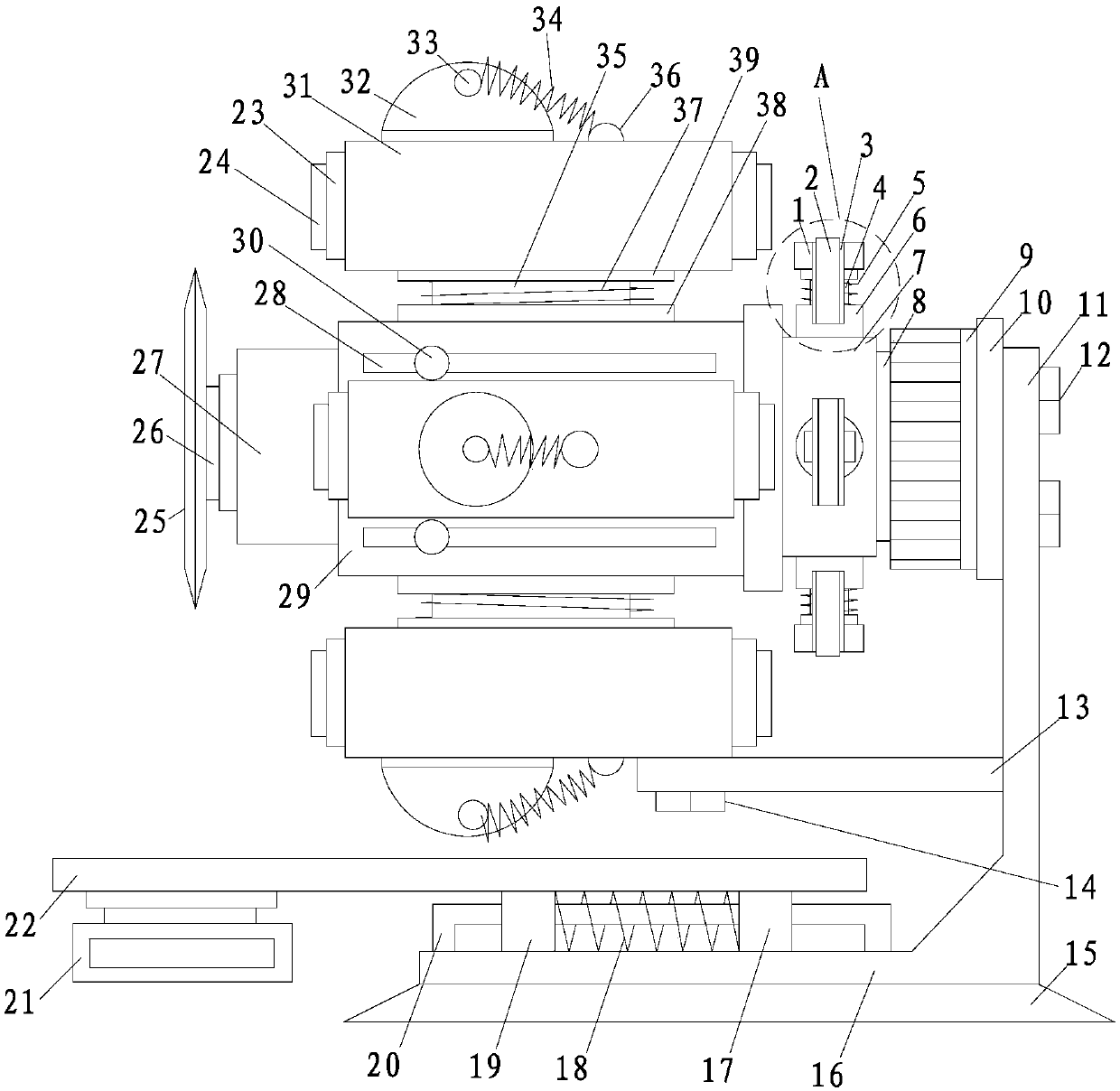

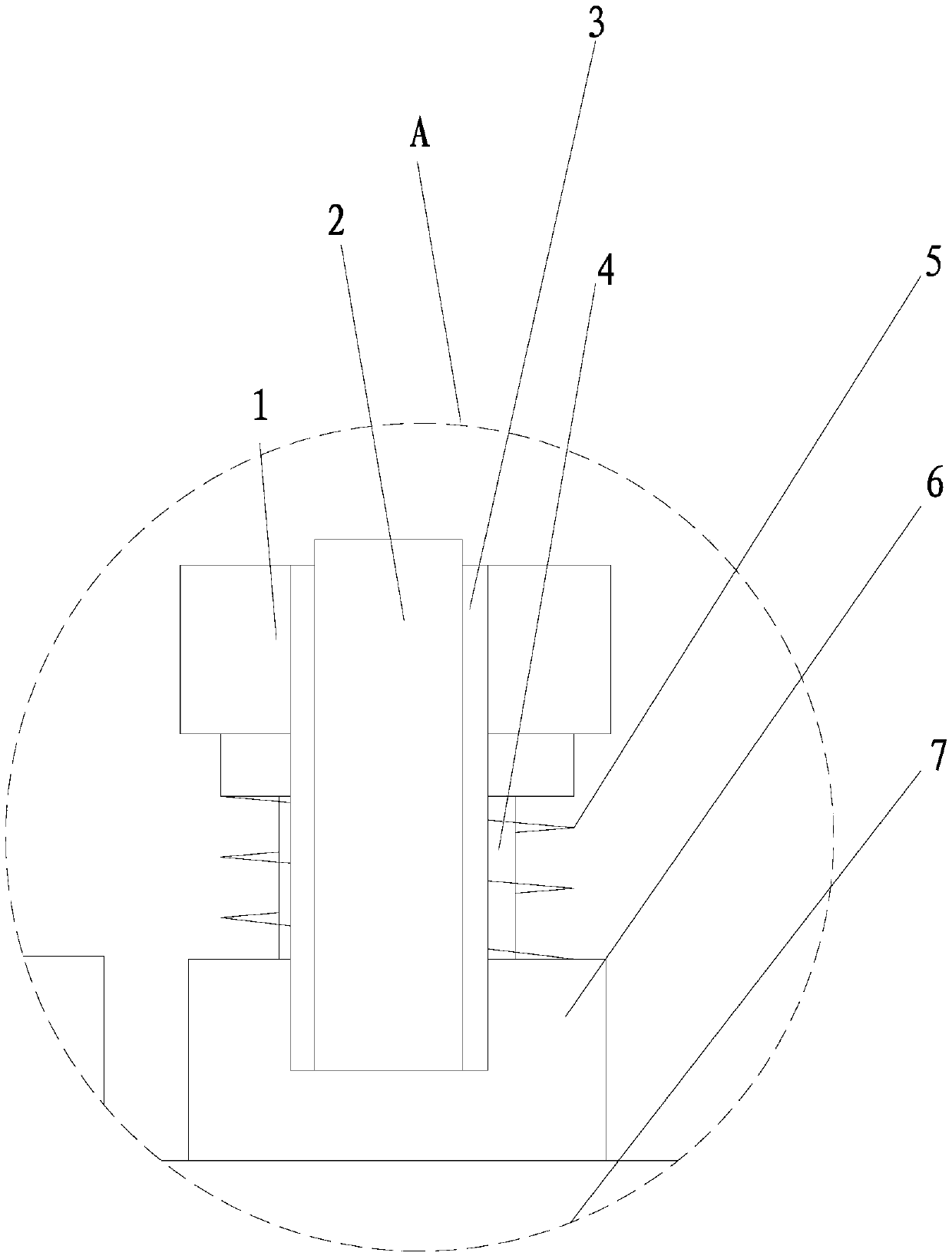

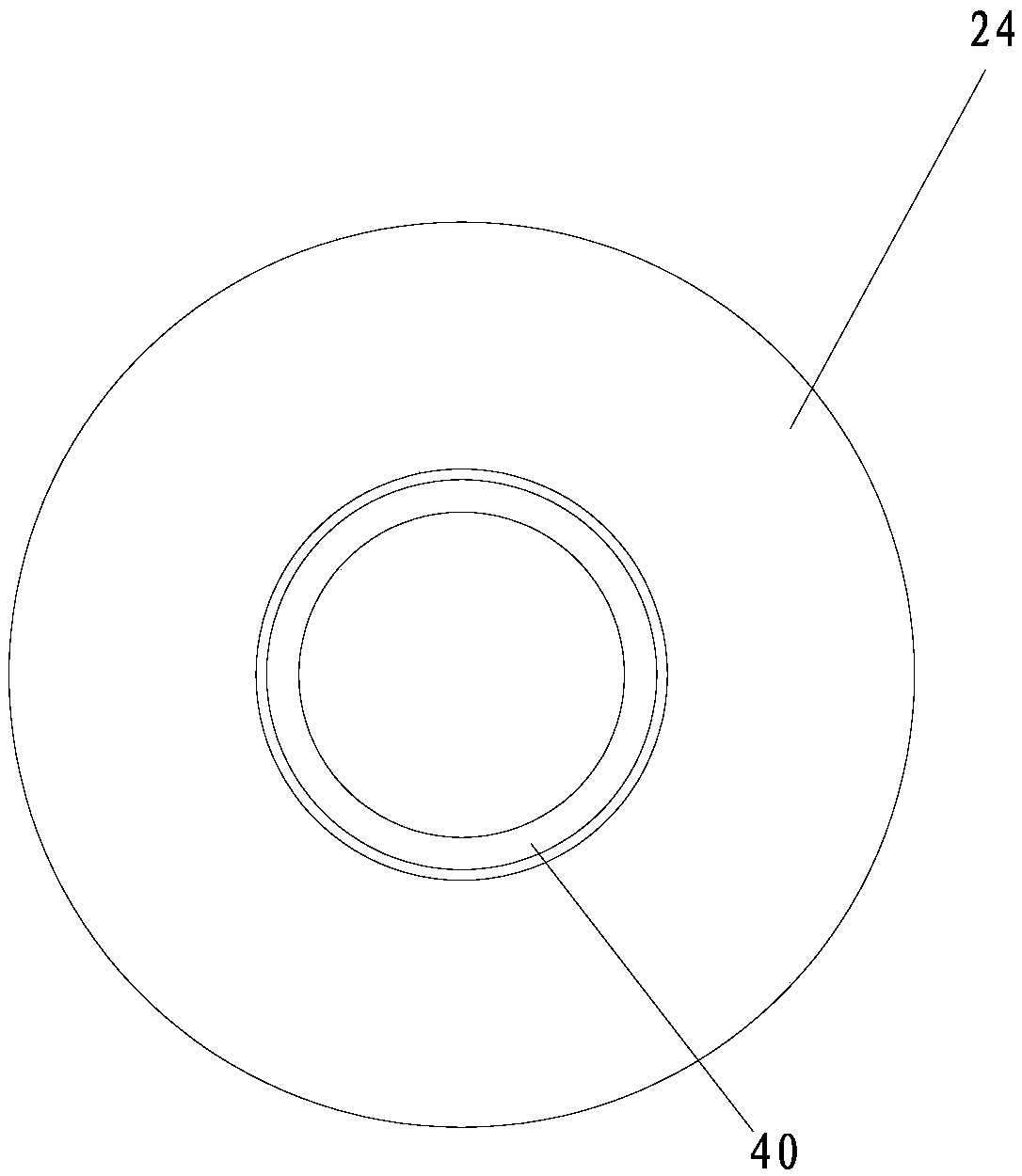

[0023] refer to Figure 1 to Figure 3 , a steel pipe cutting machine, comprising a frame, a first motor 9 mounted on the frame, a drum 7 connected to the output end of the first motor 9, a friction assembly for the steel pipe 40 to abut against and drive the steel pipe 40 to rotate , the installation cylinder 29 fitted in the rotating cylinder 7, the sleeve 31 arranged on the installation cylinder 29, the rotating tube 23 rotatably arranged in the sleeve 31, the first air bag 24 arranged in the rotating tube 23, The air supply mechanism for supplying air to the first air bag 24, the second motor 27 slidably installed in the installation cylinder 29, and the cutting disc 25 connected with the output shaft of the second motor 27, the first motor 9 The output shaft, the rotating cylinder 7 and the installation cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com