Positioning device for rapid cutting of annular parts

A rapid cutting and positioning device technology, which is applied to positioning devices, metal processing machinery parts, clamping, etc., can solve the problems that the adjustment of positioning devices is too dependent on experience, the positioning accuracy is difficult to adjust and control, and the fixture adjustment time is long, etc., to improve Cutting efficiency, strong size applicability, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

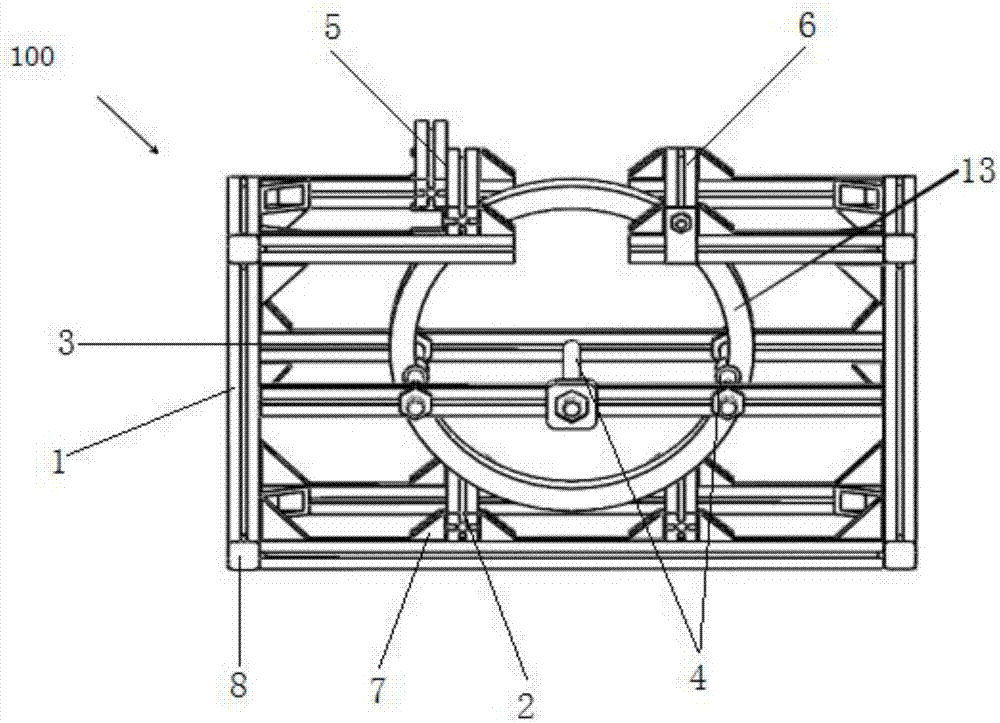

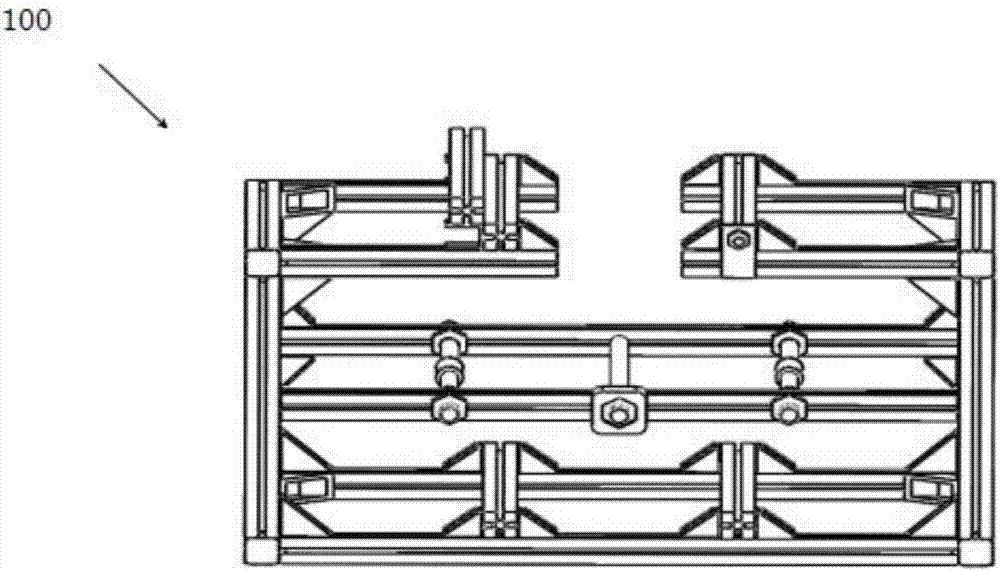

[0030] figure 1 It is a schematic diagram of the structure when cutting the workpiece in the embodiment of the present invention, figure 2 It is a schematic diagram of the overall frame structure in the embodiment of the present invention.

[0031] Such as figure 1 and 2 As shown, a positioning device for quickly cutting ring-shaped parts in this embodiment is used to position the workpiece to be cut before cutting, including: a frame 1, a first truss 2, a perforated truss 3, a positioning rod 4, two Root second truss 5, third truss 6, special triangle iron 7, square closed cover 8.

[0032] The special triangle iron 7 is arranged at the joint between the frame 1 and the truss, and is used for fixing the truss.

[0033] The square closure cover 8 is fixedly connected to the four corners of the bottom frame 101 and the top frame 103 .

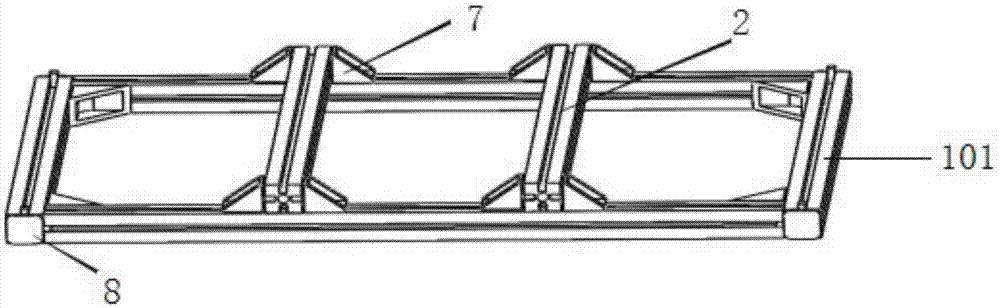

[0034] image 3 It is a structural schematic diagram of the bottom device in the embodiment of the present invention.

[0035] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com