Bidirectional self-centering fixture for workpieces

A self-centering fixture and self-centering clamping technology, used in manufacturing tools, metal processing mechanical parts, clamping and other directions, can solve the problems of waste, difficult to achieve self-centering of large cylindrical workpieces, and achieve simple and convenient expansion and contraction. , The effect of high centering accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

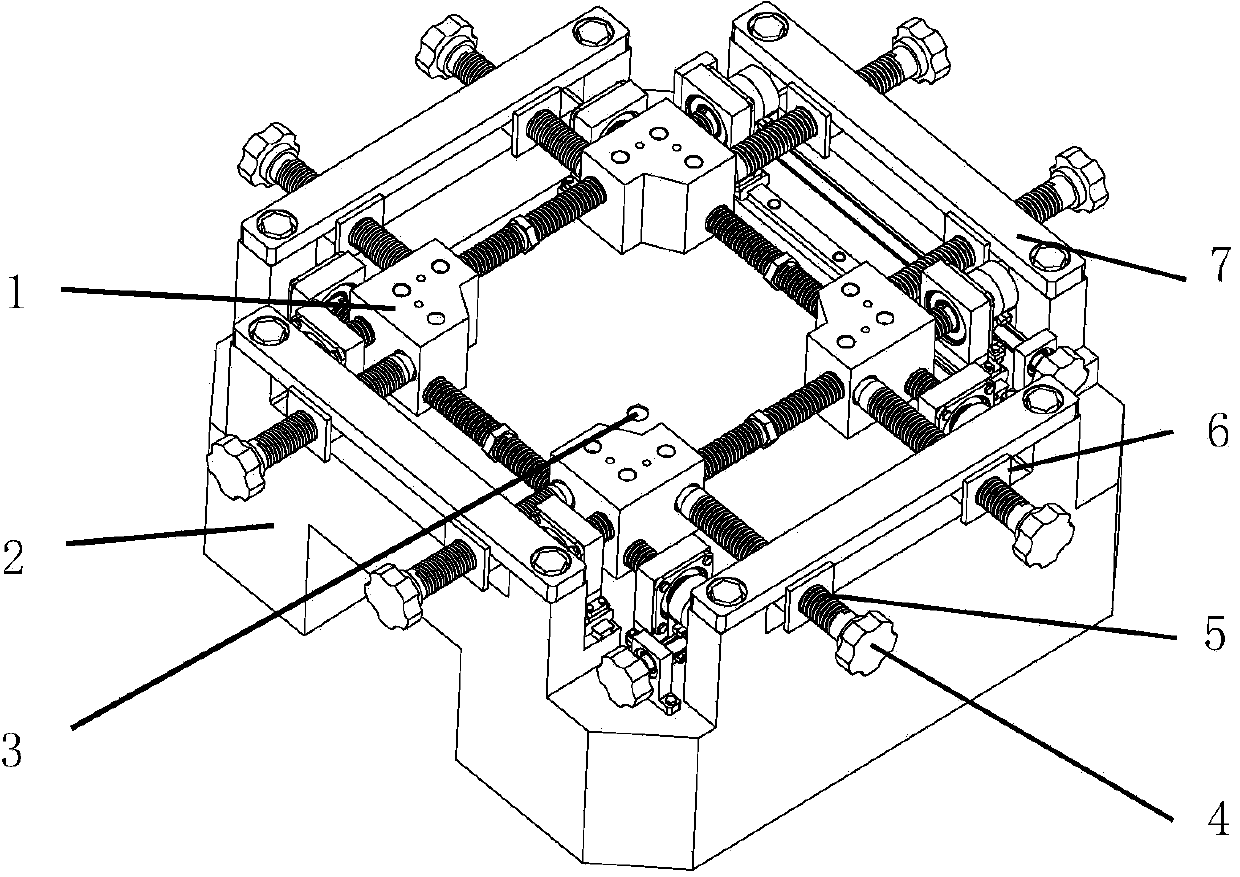

[0022] The two-way self-centering clamping mechanism 1 is fixedly connected with the base 2, the nut pressing plate 7 is fixedly connected with the base 2, the nut pressing plate 7 is press-fitted with the lock nut 6, the lock screw 5 is threadedly connected with the lock nut, and the front end of the lock screw It is a hemispherical and bidirectional self-centering clamping mechanism for top connection, the locking handle 4 is fixedly connected with the rear end of the locking screw, and the top assembly 3 is located under the through hole on the base 2;

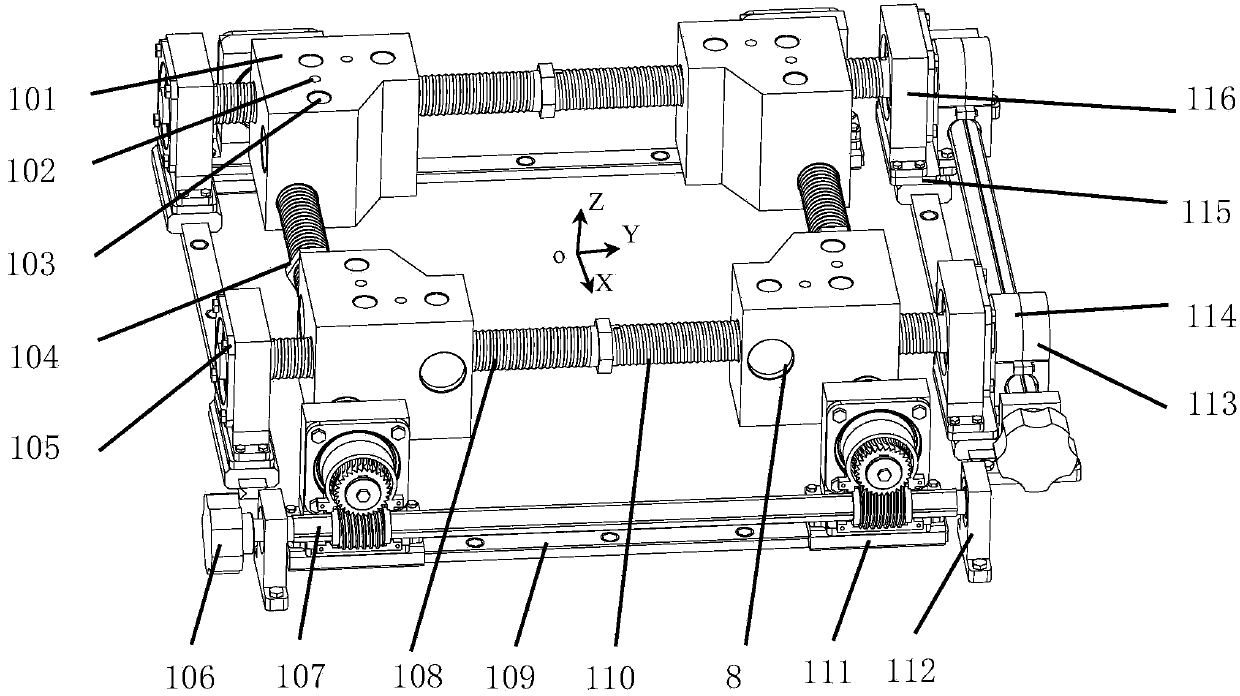

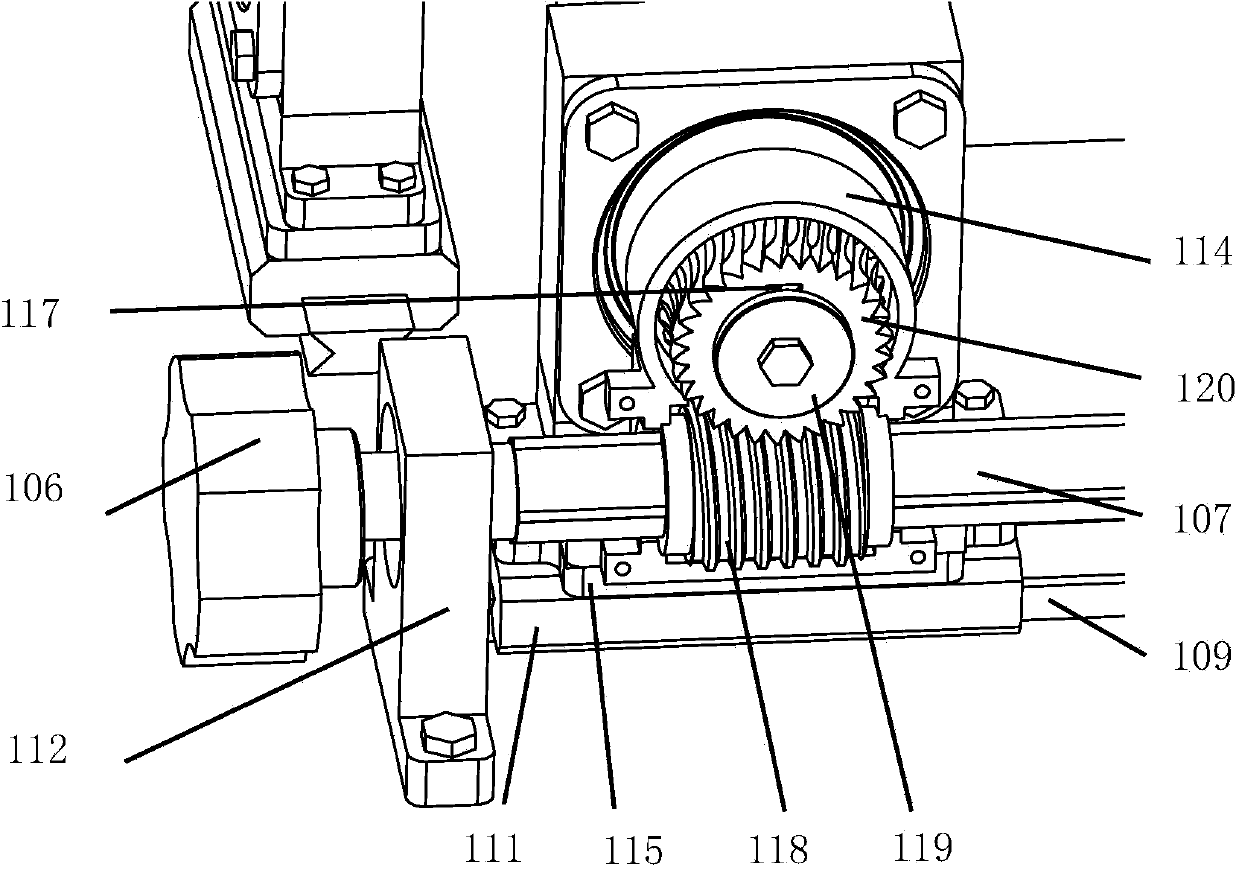

[0023] The structure of the two-way self-centering clamping mechanism 1 is: four clamping blocks 101 are arranged in combination to form a rectangular shape, and the upper end of each clamping block 101 has three bolt holes 103 and two positioning pin holes 102, reverse rotation The double-threaded screw 104 has two threads, separated from the middle, one left-handed thread 108, and the other right-handed thread 110. The two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com