Flexible supporting device

A technology of flexible support and support rods, applied in positioning devices, clamping devices, supports, etc., can solve the problems of low positioning accuracy and low machining accuracy of complex thin-walled blade parts, achieve accurate support force, and ensure high-speed and efficient processing Accuracy and processing quality, the effect of stable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

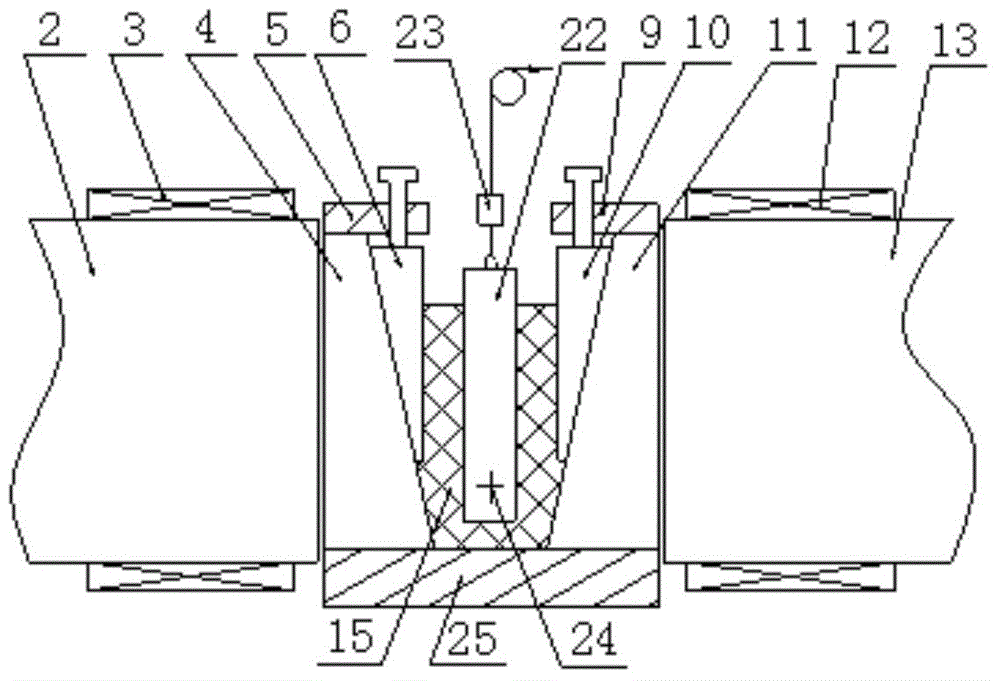

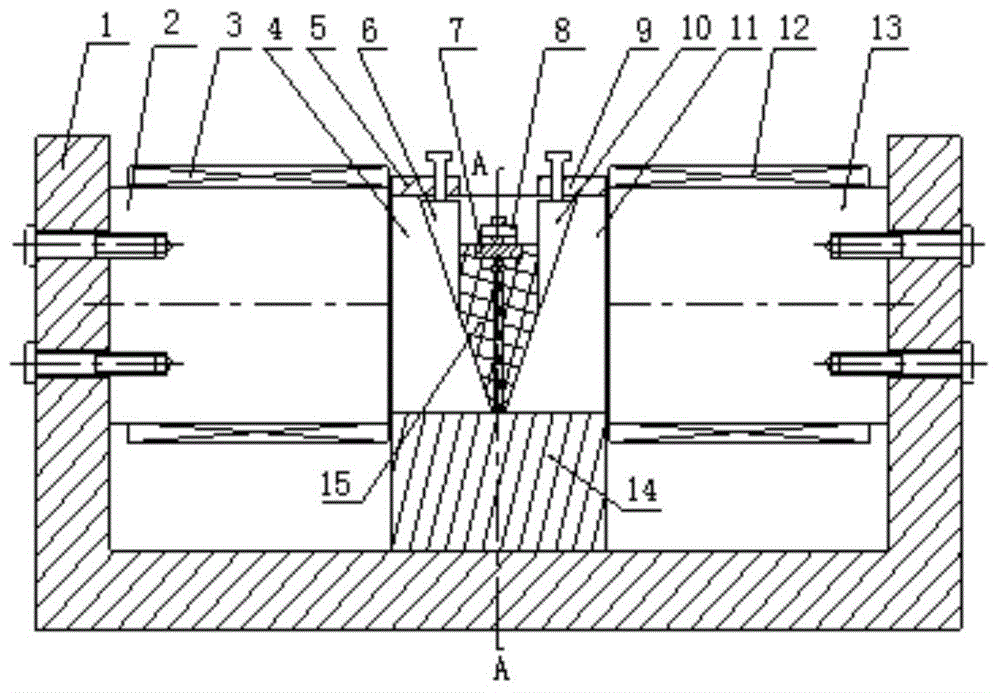

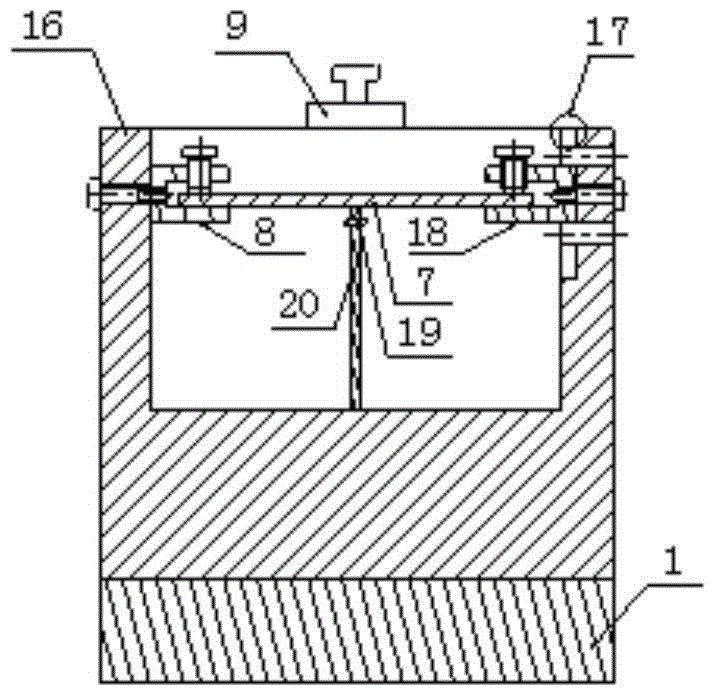

[0015] The following examples refer to Figure 2-4 .

[0016] The flexible supporting device of the present invention comprises a left iron core 2, a left excitation coil 3, a left wedge-shaped guide container wall 4, a left support plate 5, a left wedge-shaped block 6, a right support plate 9, a right wedge-shaped block 10, a right wedge-shaped guide container wall 11, The right excitation coil 12, the right iron core 13 and the magnetorheological fluid 15 also include a frame 1, a left initial positioning device 8, a right initial positioning device 18, a displacement sensor 19, a support rod 20 and a DC stabilized voltage power supply 21.

[0017] Frame 1 is a U-shaped structure made of No. 45 steel, with a size of 500×200×250mm; the left wedge-shaped guide container wall 4 and the right wedge-shaped guide container wall 11 are made of No. 45 steel materials, and the left wedge-shaped guide container wall 4 and The inner side of the right wedge-shaped guide container wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com