Rotational multi-workpiece clamping and multi-station pneumatic clamp

A pneumatic fixture, multi-station technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of low processing efficiency, troublesome operation, and many times of loading and unloading, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

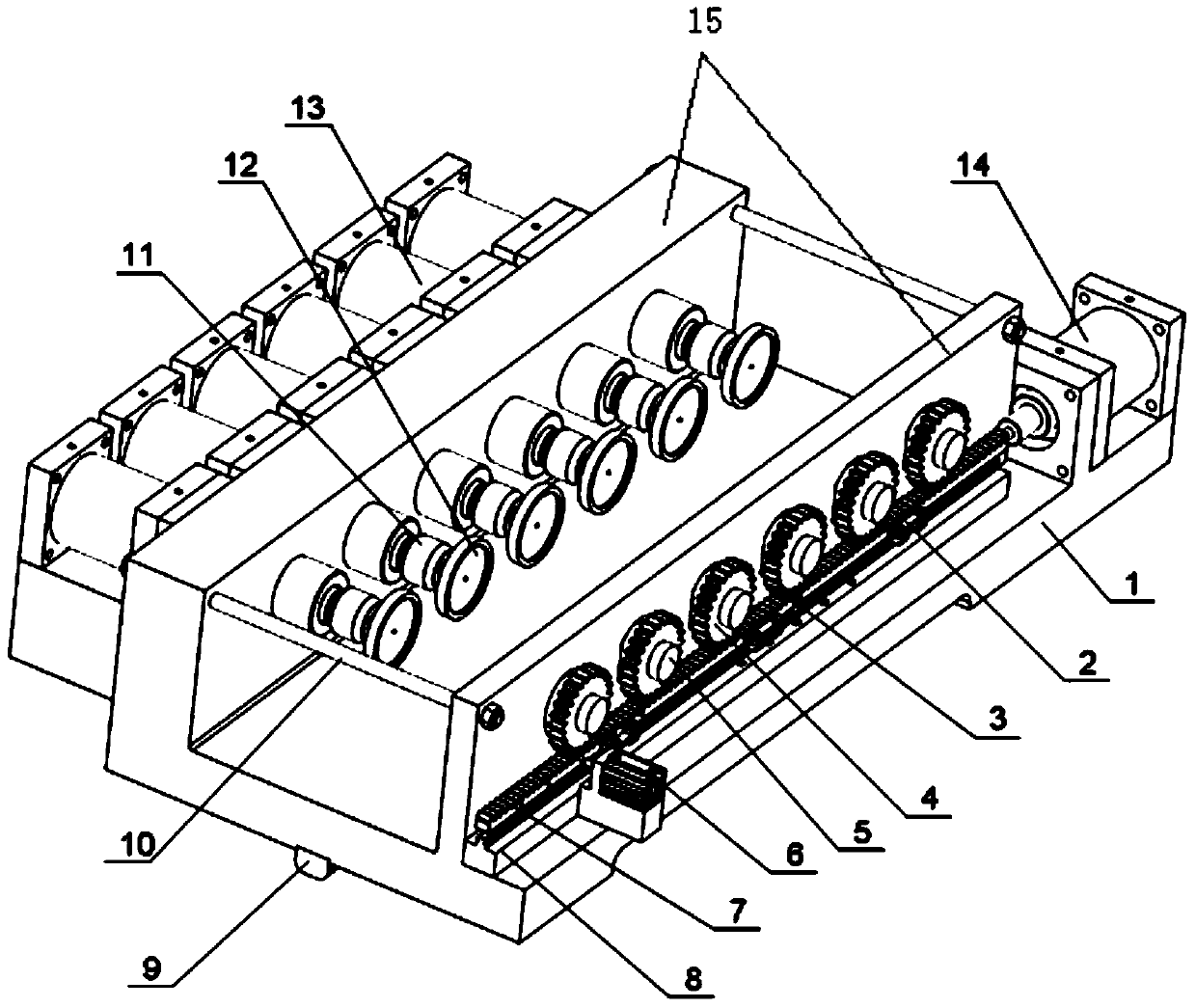

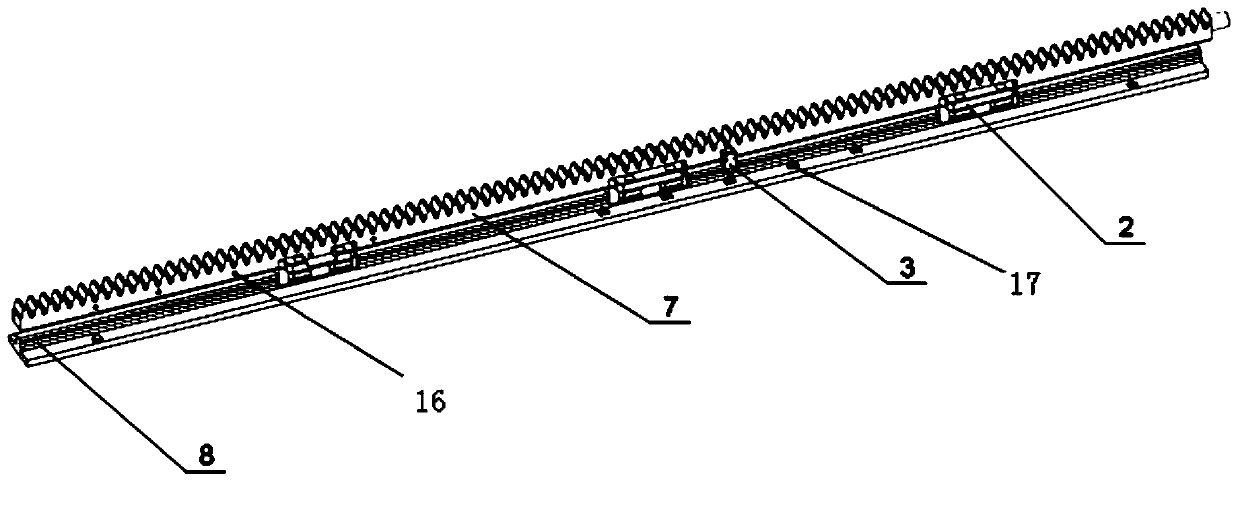

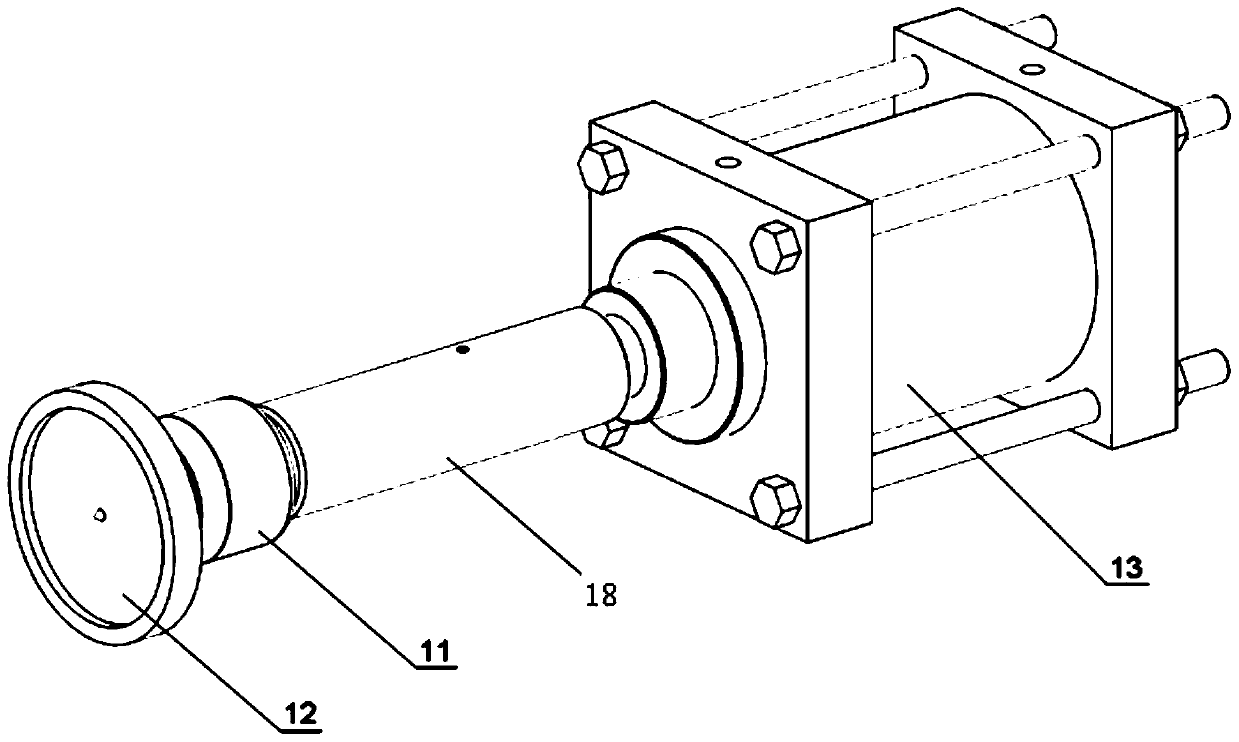

[0023] refer to Figure 1~Figure 4 , the present invention is a pneumatic clamp capable of fulfilling the requirements of six workpiece clamping and four station rotation positioning, including a clamp body 1 with two parallel vertical vertical plates 15; a vertical vertical plate installed on one side of the clamp body 1 15 positioning and rotating mechanism, the positioning and rotating mechanism is composed of driving cylinder 14, rack 7, slide block 2, guide rail 8, limit switch 3, positioning cylinder 6, cylindrical gear 4, rotating shaft 5 and positioning plate for positioning the workpiece, positioning The clamping mechanism installed on the vertical vertical plate 15 on the other side of the clamping body 1 is composed of components such as the clamping cylinder 13, the rolling ejector rod 11 and the briquetting block 12.

[0024] In order to ensure that the position of the fixture on the machine table is accurate, two orientation keys 9 are installed on the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com