Blade inherent frequency automatic testing system

An automatic testing system and natural frequency technology, applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve problems such as restricting technological development and low testing efficiency, and achieve low technical level requirements, improve technical level and The effect of test efficiency and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

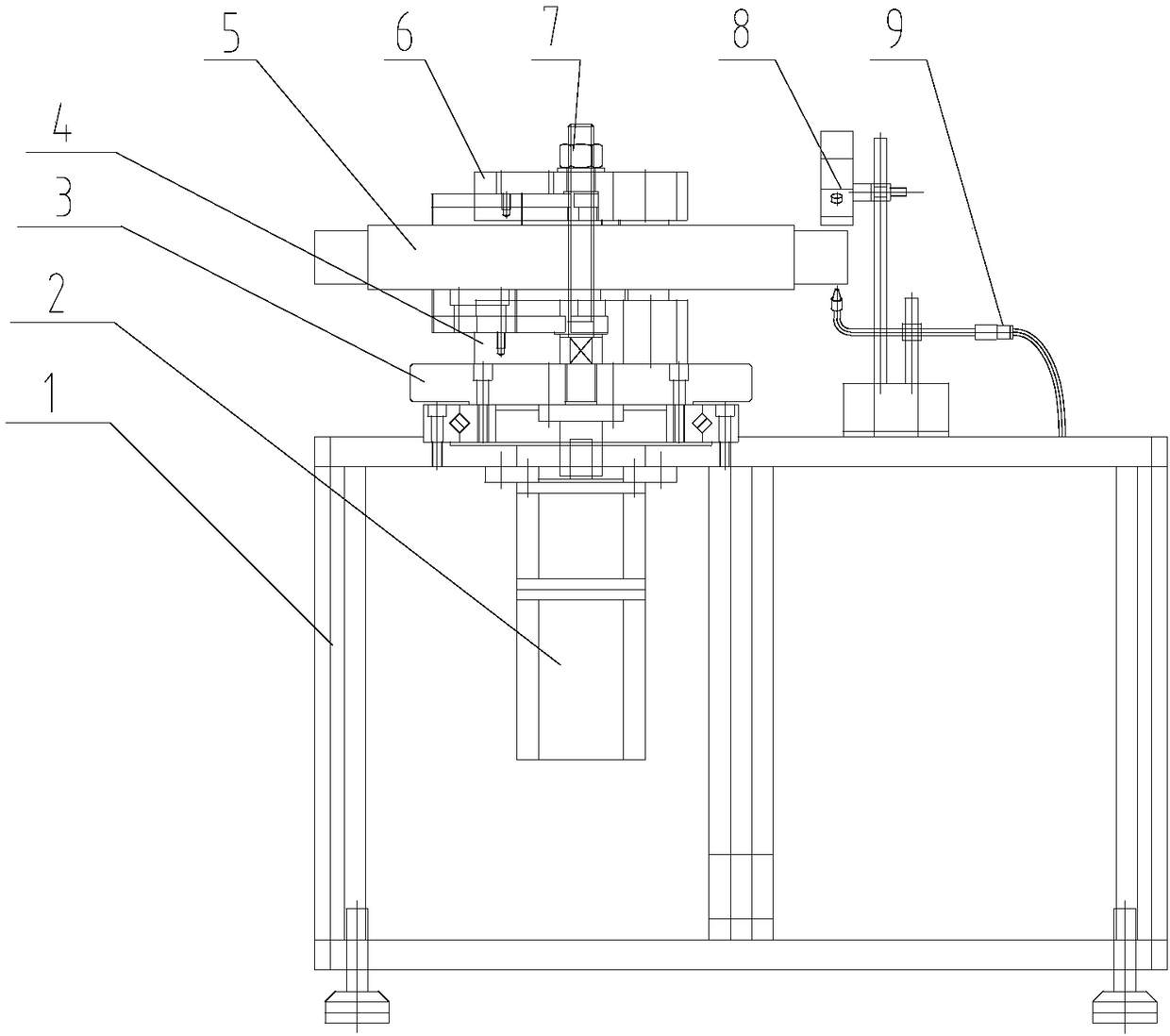

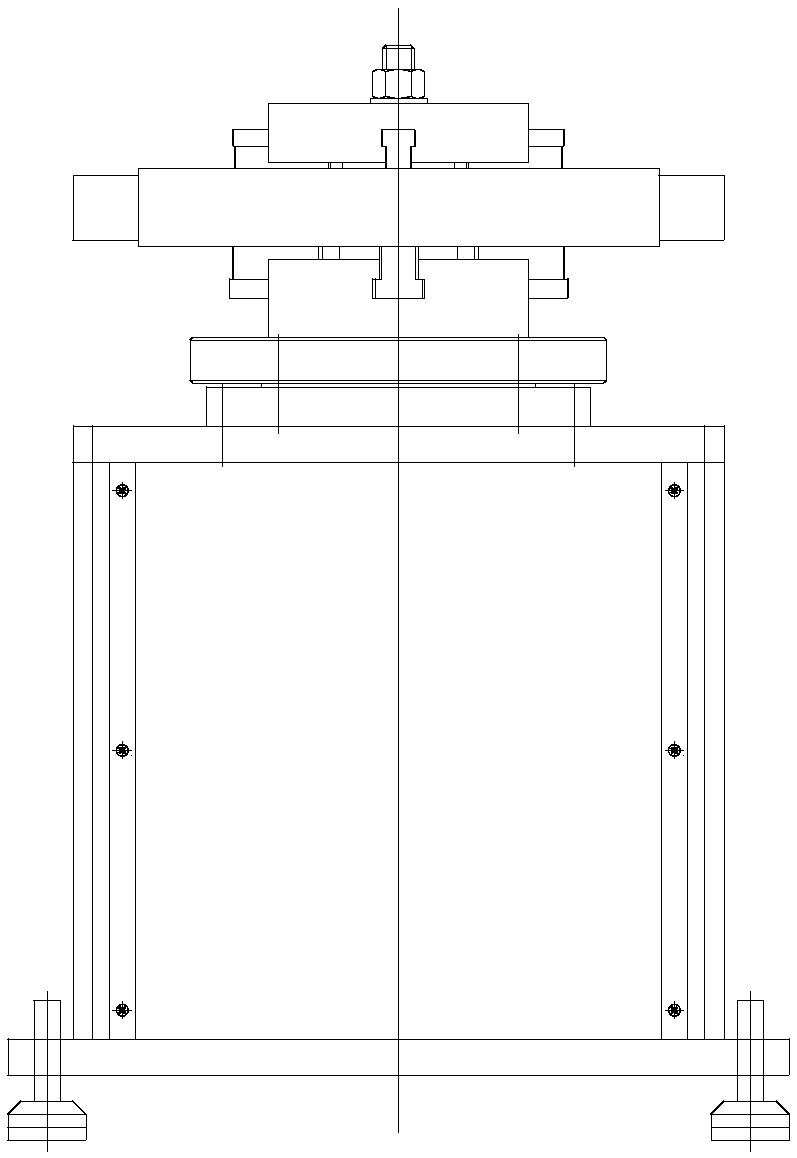

[0022] see Figure 1-Figure 8 , The main contents of the present invention include: 1) universal blade clamping and automatic rotation drive mechanism; 2) automatic jet excitation, automatic displacement acquisition and control system; 3) natural frequency automatic test and identification system. in:

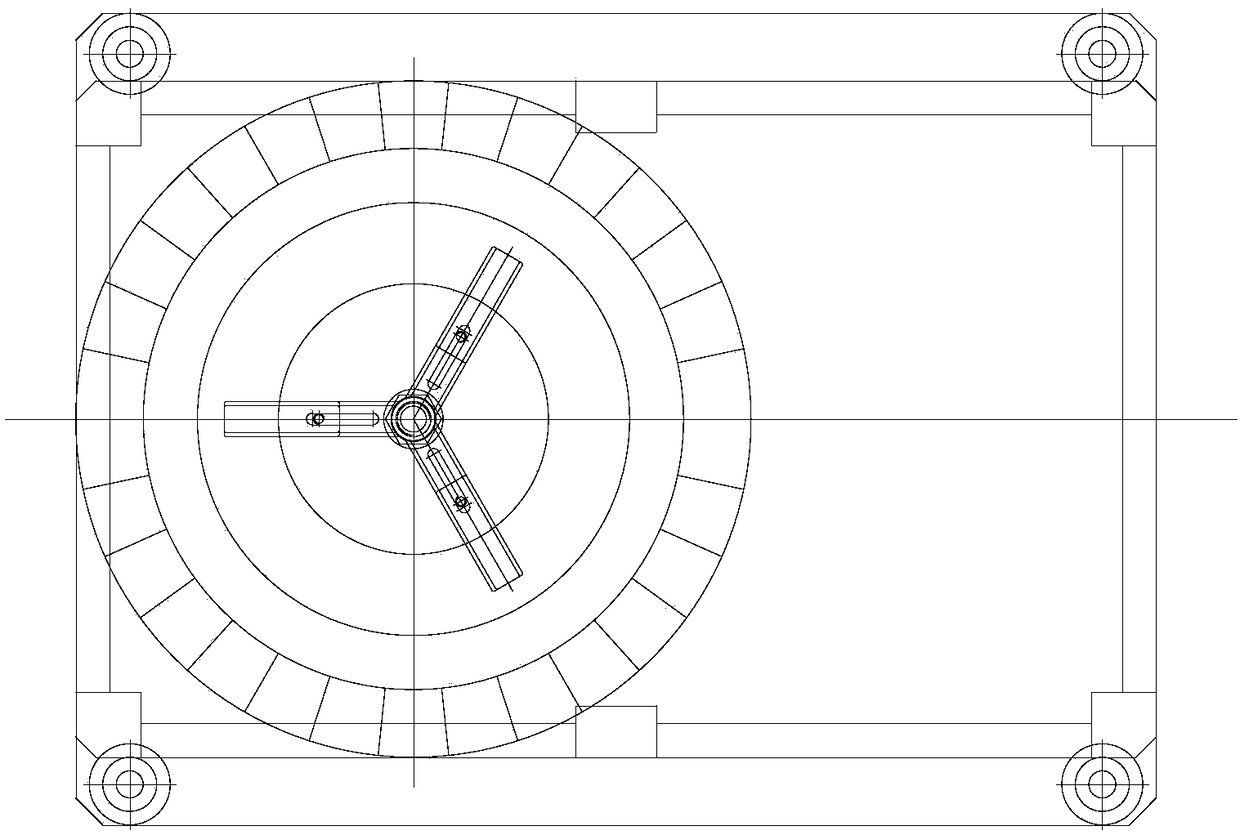

[0023] The main features of the universal blade clamping and automatic rotation drive mechanism are that blades of different sizes can be installed and automatic rotation control can be realized. Clamping consists of a base and a rotating disk". The rotating disk is the blisk, which is clamped by the clamping disk, and the stepping motor is used to drive the clamping disk to rotate (thereby driving the rotating disk to rotate), and the stepping motor is composed of The master computer is controlled by maintaining communication with the PLC controller.

[0024] The clamping disc is installed on the rotating disc, and the upper and lower clamping discs adopt a three-claw mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com