Main shaft online indexing module of numerical control wire-cut machine tool and use method of main shaft online indexing module

A wire cutting machine tool and spindle technology, used in metal processing machinery parts, electric processing equipment, precision positioning equipment, etc., can solve the problems of spindle rotation motion matching, increasing difficulty and cost, and inability to process complex shapes of spiral grooves. The effect of convenient loading and unloading, low cost and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

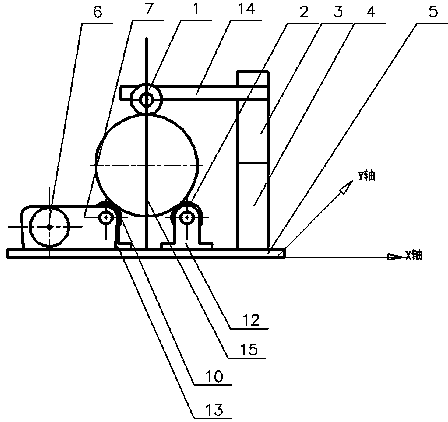

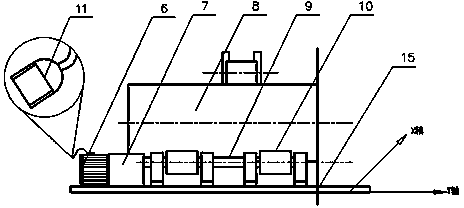

[0022] combined with Figure 1-6 , to further describe the present invention:

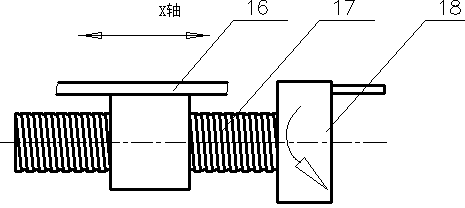

[0023] An online spindle indexing module of a CNC wire cutting machine tool, including an upper driven roller 1, a lower driven roller 2, a slider 3, a fixed rail frame 4, a base 5, a drive motor 6, a servo reducer 7, and a workpiece 8 , transmission shaft 9, driving roller 10, fixed guide rail frame 4 is installed on the base 5, drive motor 6, servo reducer 7, lower driven roller bracket 12 and driving roller bracket 13 are installed on one side of fixed rail frame 4, fixed guide rail The top of frame 4 is provided with slide block 3, and the top of slide block 3 is provided with cross bar 14; Described lower driven roller bracket 12 and driving roller bracket 13 are respectively installed lower driven roller 2 and driving roller 10, and described The upper driven roller 1 is installed on the outer end of the cross bar 14, and the upper driven roller 1, the lower driven roller 2 and the driving r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com