A Large Adjustable Frame Structure Welding Fixture

A frame structure, welding fixture technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of not being able to clamp various workpieces of different sizes, and the limited ability to adapt to workpieces, and achieve fast clamping. Convenience, strong adaptability to workpieces, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

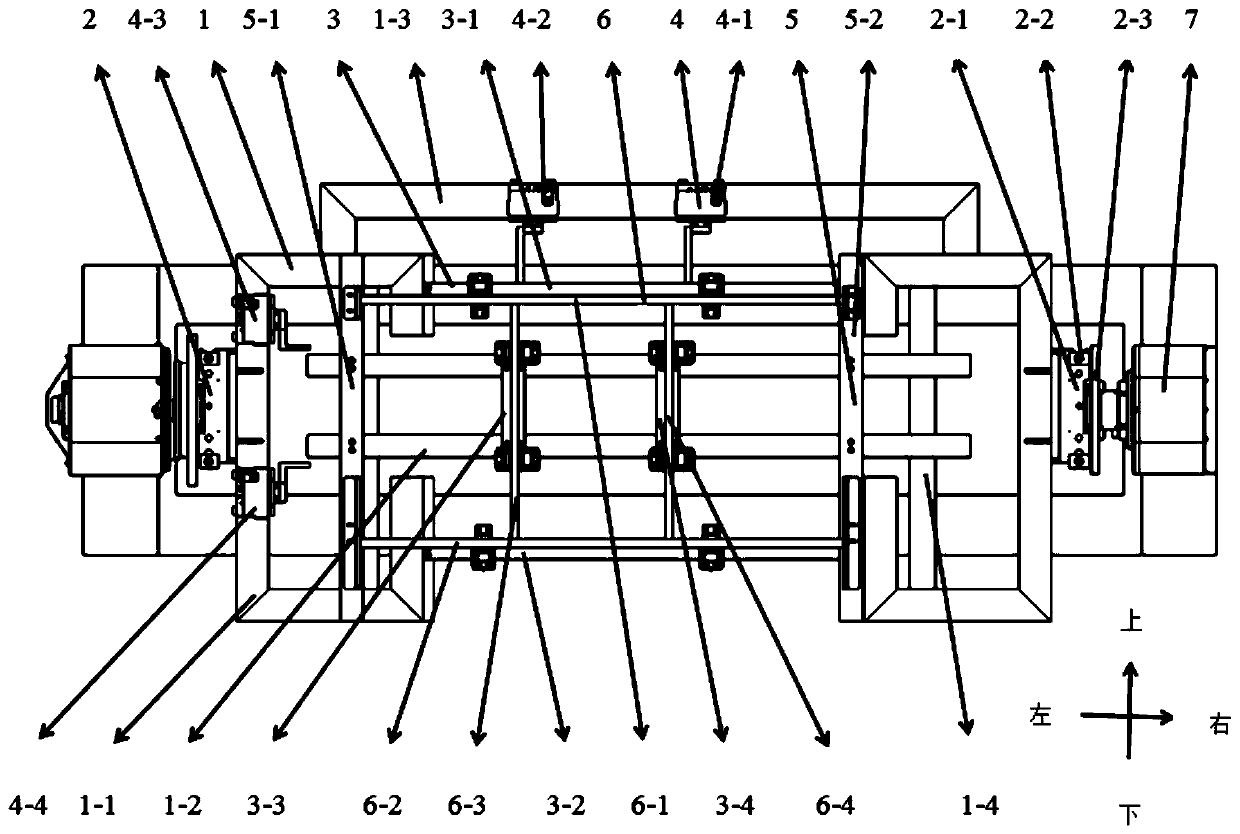

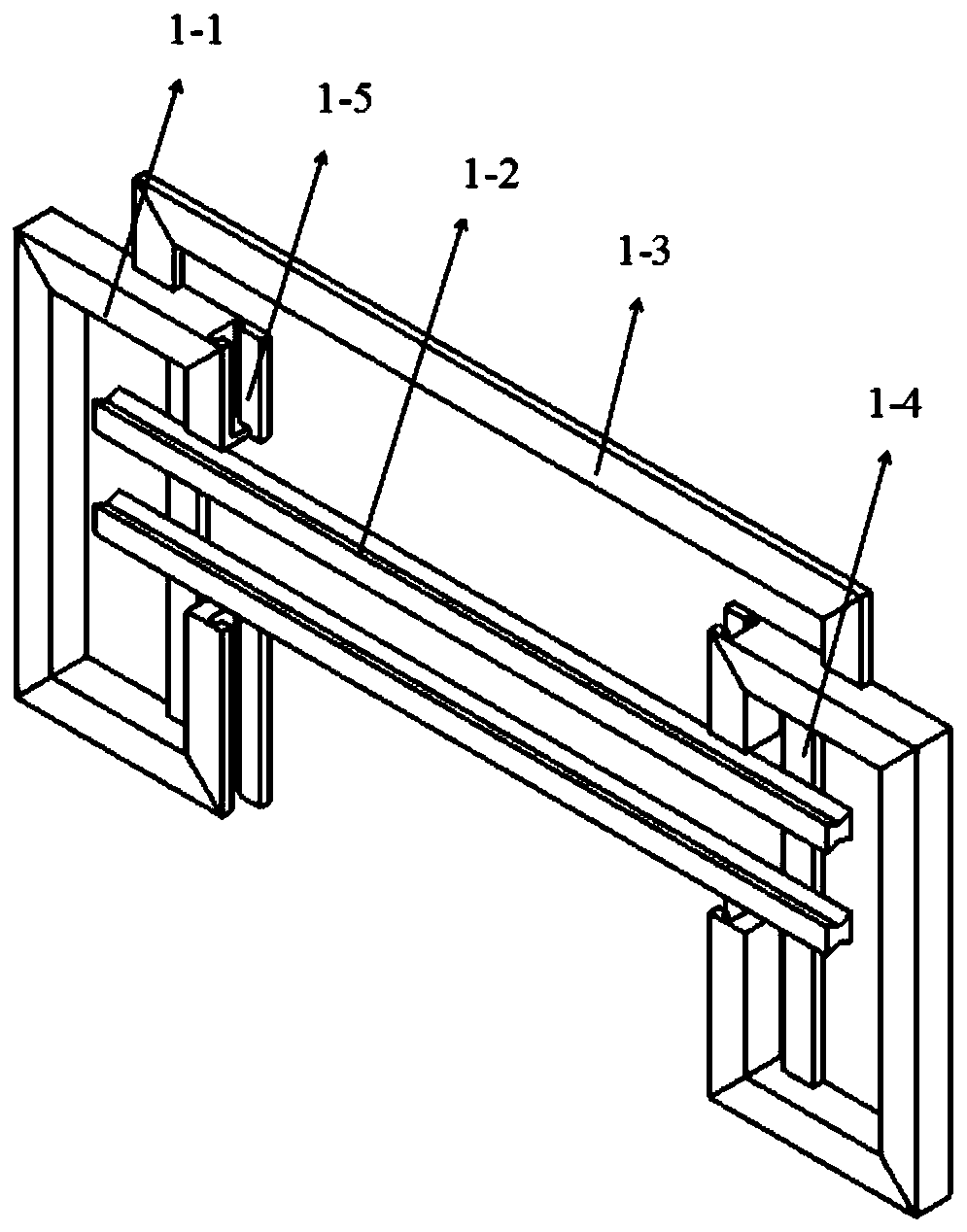

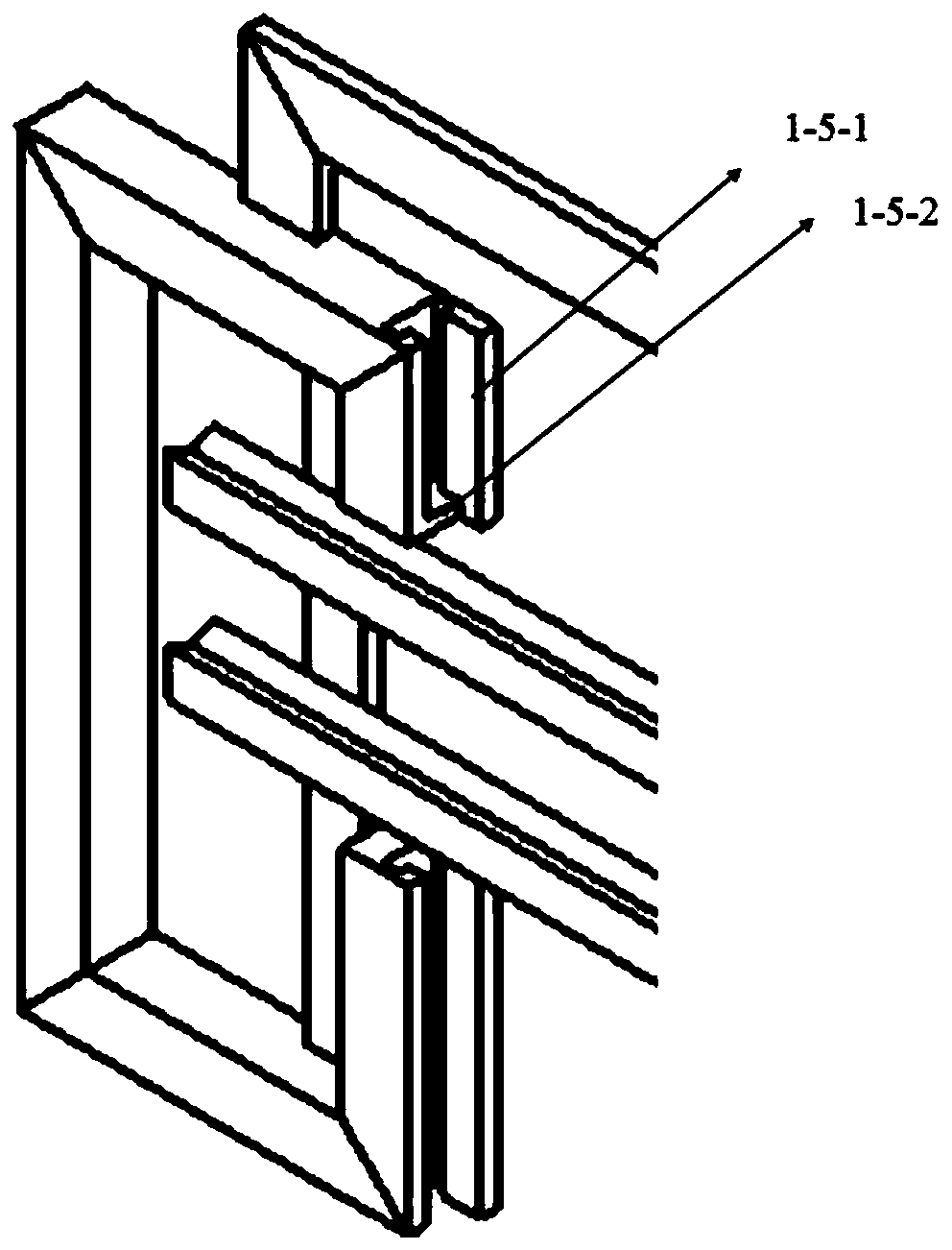

[0036] Such as Figure 1 to Figure 13 As shown, it includes a fixture base 1, a quick change structure 2, a fixing unit 3, a pressing unit 4, a positioning unit 5, a workpiece 6 and a turning positioner 7, and the fixture base 1 ( figure 2 ) is made up of square frame 1-1, guide rail 1-2, connecting beam 1-3, guide rail support beam 1-4, described quick change structure 2 ( Figure 4 ) is composed of clamp quick-change joint 2-1, flip-over positioner quick-change joint 2-2 and connecting bolt 2-3, and the fixing unit 3 ( Figure 5 ) consists of an upper fixture 3-1, a lower fixture 3-2, a left fixture 3-3, and a right fixture 3-4, and the pressing unit 4 ( Figure 8 ) includes an upper right pressing device 4-1, an upper left pressing device 4-2, an upper left pressing device 4-3 and a left lower pressing device 4-4, and the positioning unit 5 ( Figure 10 ) is made up of left positioning device 5-1 and right positioning device 5-2, and described workpiece 6 ( Figure 12 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com