Multi-axis multi-station automatic welding equipment

A fully automatic welding, multi-station technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of cumbersome manual welding operations, endanger the health of operators, occupy a large space, etc., and achieve improvement Versatility and scope of application, stable solder joint switching efficiency, and low equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

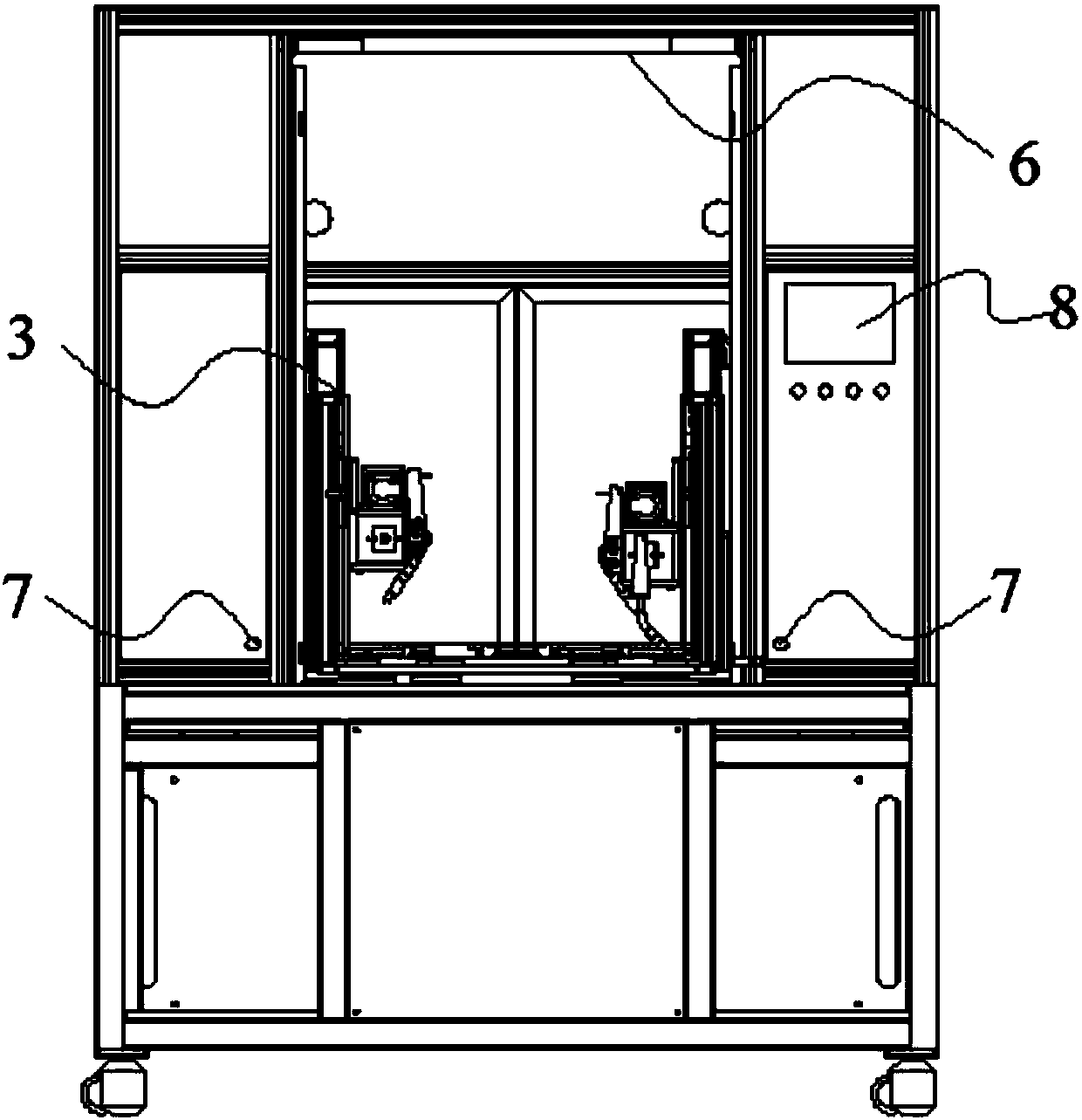

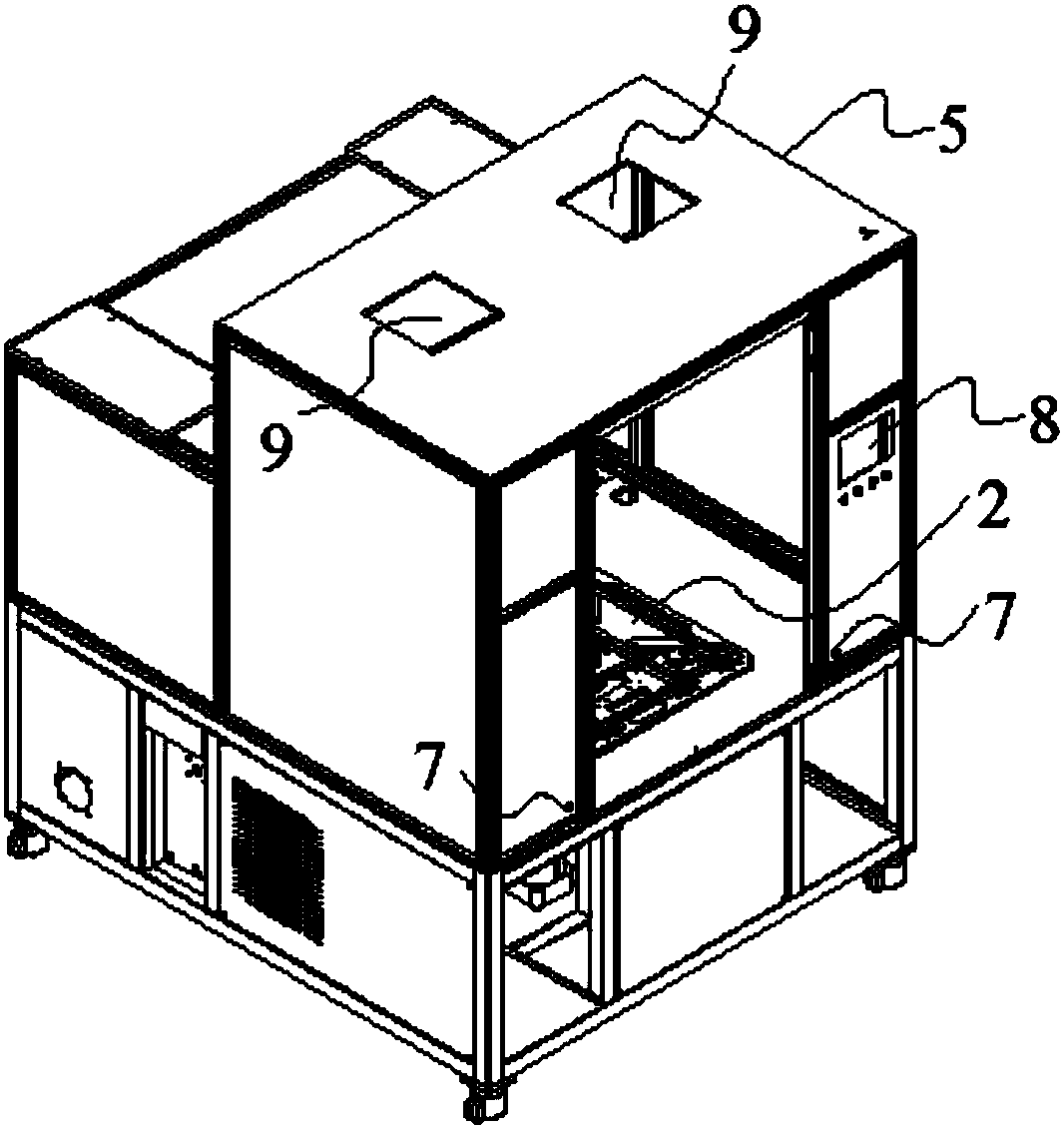

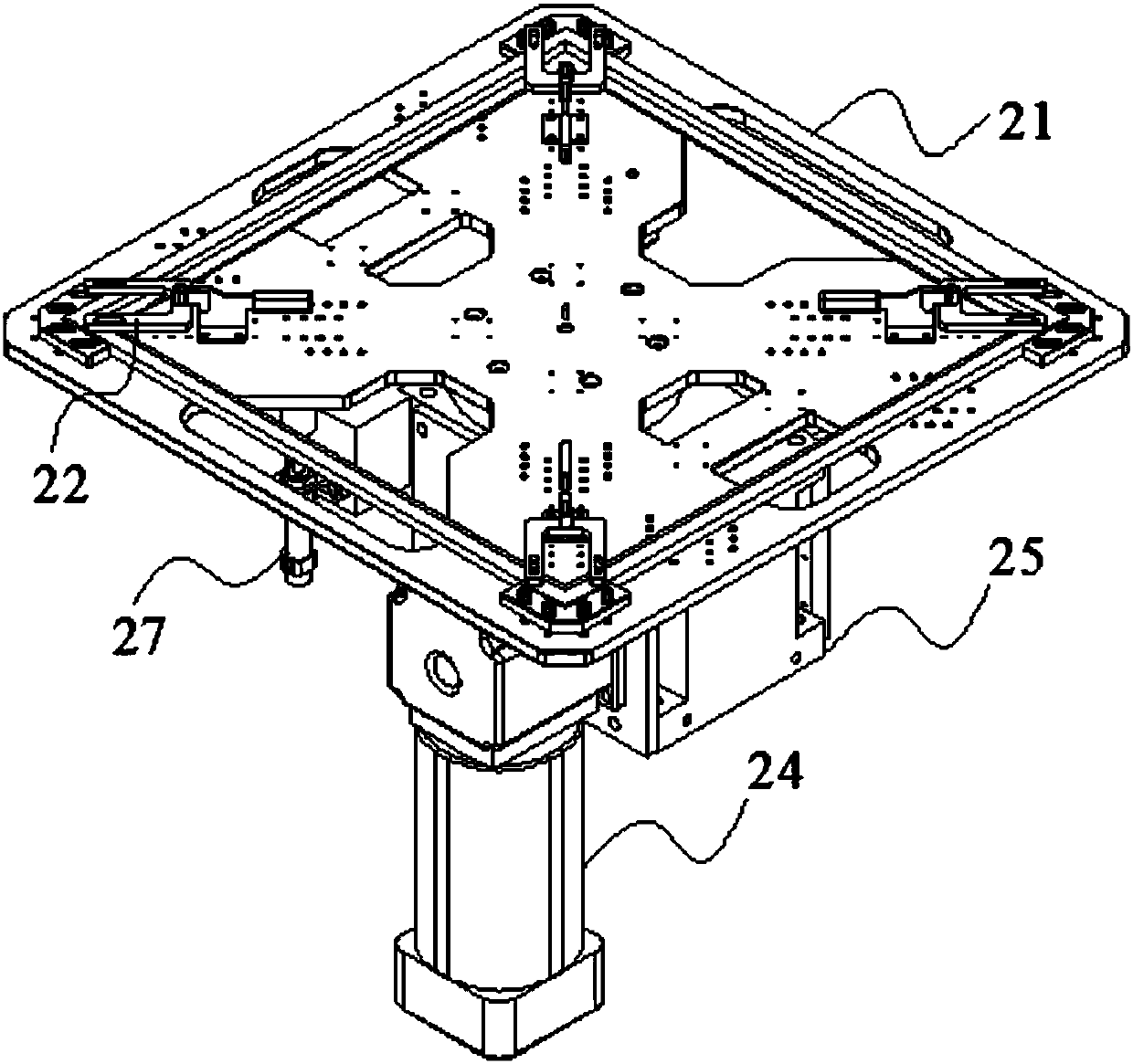

[0036] Embodiment 1: multi-axis multi-station automatic welding equipment, such as Figure 1-8 As shown, the present invention includes a welding machine, a wire feeder and a welding torch 1, and also includes a control system and at least one fixed rotating platform 2 for fixing workpieces and capable of horizontal rotation;

[0037] The fixed rotating platform 2 is connected with a rotation drive mechanism that drives the horizontal rotation of the fixed rotating platform 2; each of the fixed rotating platforms 2 corresponds to at least one manipulator 3, and each of the manipulators 3 is fixedly connected with one of the A welding torch 1, the welding torch 1 is connected to the wire feeder through a gun barrel, and the fixed rotating platform 2 and the welding torch 1 are respectively electrically connected to the welding machine;

[0038] The welding machine, the wire feeder, the manipulator 3 and the rotation driving mechanism of the fixed rotating platform 2 are all ele...

Embodiment 2

[0050] Embodiment 2: Multi-axis multi-station automatic welding equipment, the rest is the same as Embodiment 1, the difference is that this embodiment is not provided with a protective cover, and the fixed rotating platform, the manipulator and the welding torch are located in an open in the space. This embodiment is applicable to the processing workshop itself equipped with a central exhaust fan and dust collection equipment, and the operator has certain protective measures. The smoke and radioactive substances generated during the welding equipment processing can be extracted in time through the exhaust fan and collected in the dust collection equipment. , to ensure that the environmental quality of the processing workshop is qualified.

Embodiment 3

[0051] Embodiment 3: Multi-axis multi-station fully automatic welding equipment, the rest is the same as Embodiment 1, the difference is that this embodiment is provided with two fixed rotating platforms before and after, and at least A manipulator, the manipulator is a three-axis manipulator composed of X-axis, Y-axis and Z-axis, the X-axis is horizontally fixed on the fixed rotating platform, the Z-axis is perpendicular to the X-axis and on the motor Driven to move left and right on the X-axis, the Y-axis is perpendicular to the Z-axis and moves up and down on the Z-axis driven by the motor, the Y-axis can move forward and backward under the drive of the motor, and the Y-axis A welding torch is respectively provided at the front and rear ends of the shaft, and the two welding torches are connected to the Y-axis through a rotating mechanism. An organ cover that can move back and forth along the Y-axis is arranged between the two welding torches. The manipulator Located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com