Machining method of high-precision inner circular hole of thin-wall special-shaped pipe

A processing method and technology for special-shaped pipes, which are applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., to achieve the effect of good folding effect, low processing cost, and improved qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present application will be described in further detail below in conjunction with the examples, but the implementation manner of the present application is not limited thereto.

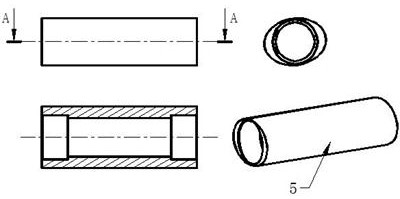

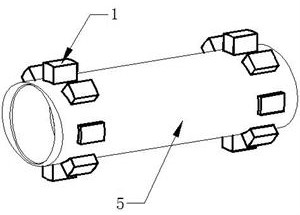

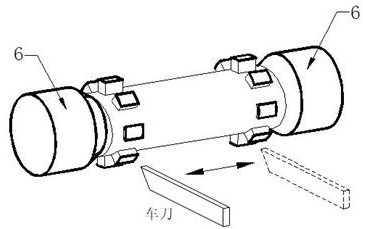

[0031] Refer to the attached figure 1 , the thin-wall special-shaped pipe has the following characteristics: the shape of the pipe fitting is a non-circular structure, the wall thickness of the pipe fitting is thin, there is a through hole in the middle, and there are high-precision step holes at both ends. Therefore, traditional chucks cannot directly clamp thin-walled special-shaped tubes for processing. Therefore, this embodiment discloses a processing method for high-precision inner circular holes of thin-walled special-shaped tubes, which solves the clamping problem of thin-walled special-shaped tubes during processing. The processing and clamping of special-shaped pipes mainly includes aluminum spacer 1, end cap 2, slotted bushing 3 and positioning ring 4. The processing method speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com