A device and method for automatically aligning and clamping ring-shaped parts

A ring-shaped, positive-loading technology, used in positioning devices, metal processing machinery parts, clamping and other directions, to improve processing efficiency, reduce parts clamping time, and reduce workpiece alignment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

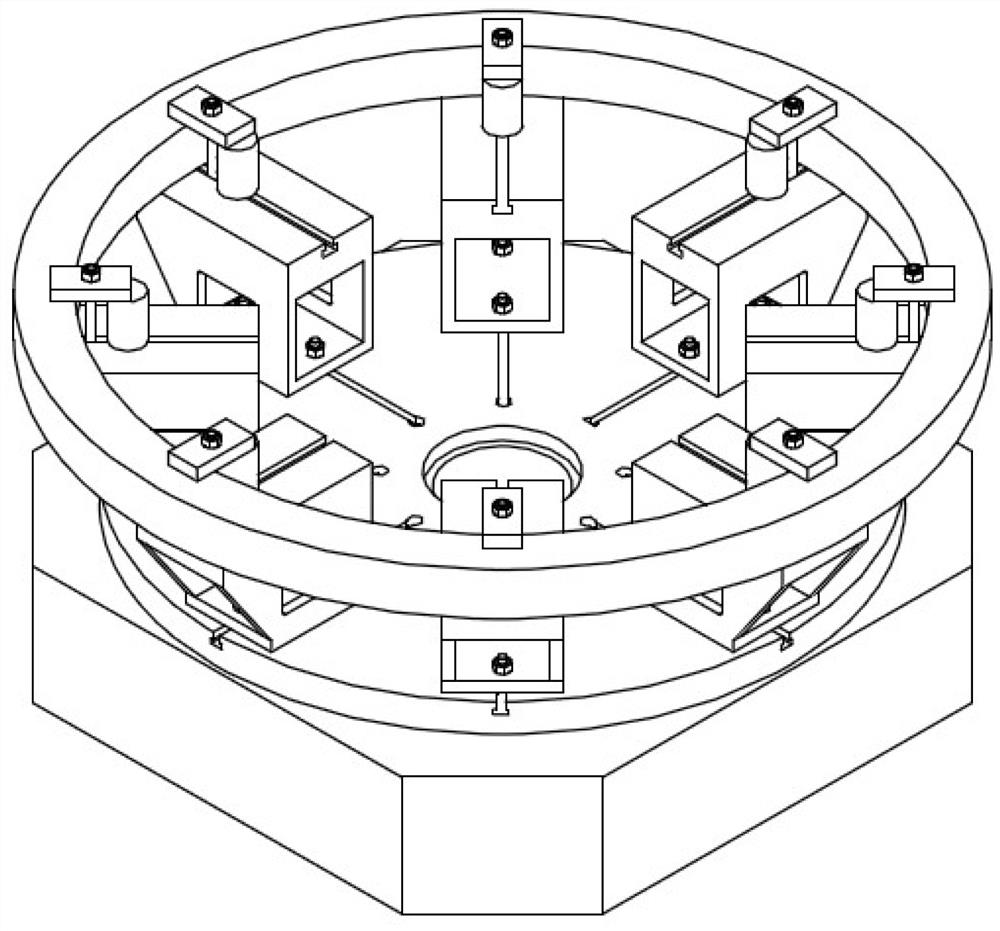

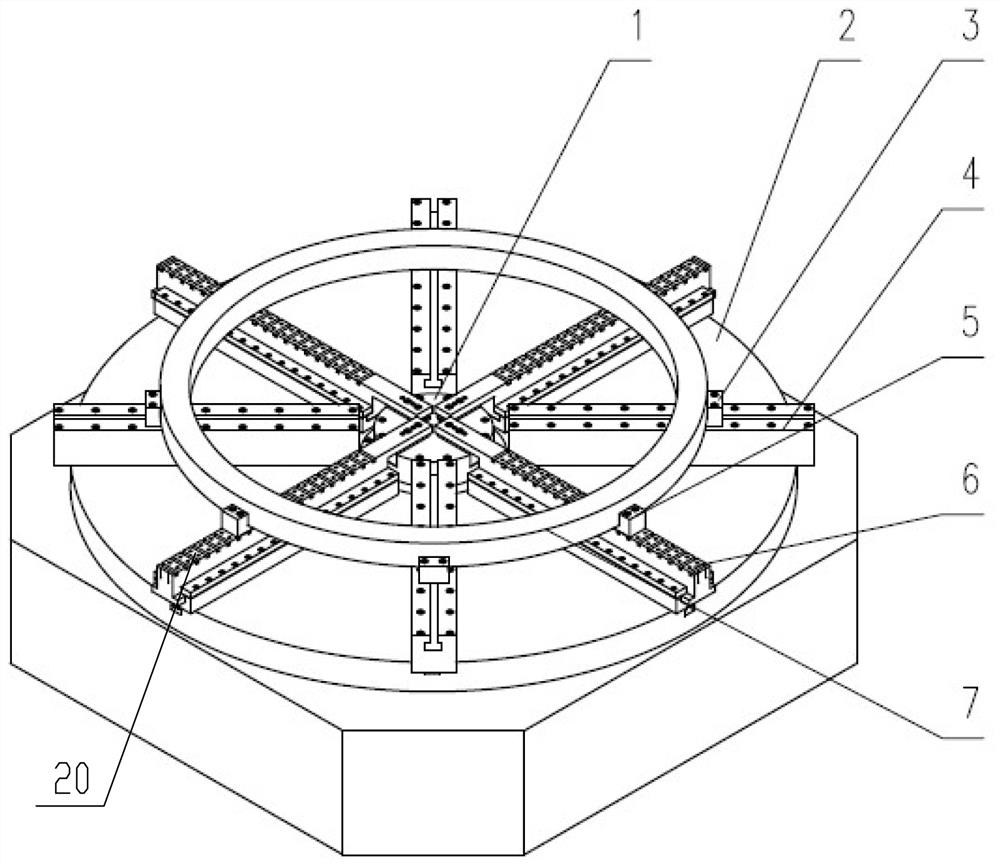

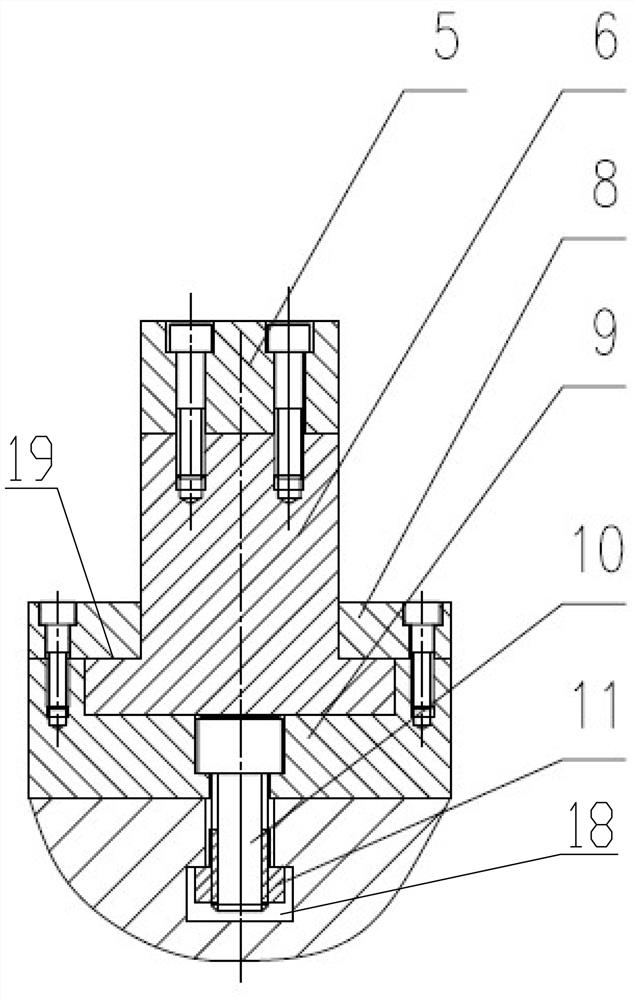

[0036] see Figure 2-4 , an automatic aligning and clamping device for ring-shaped parts, which includes a rotary table 2, a power chuck 1 is fixedly installed in the center of the rotary table 2; the rotary table 2 is located on the power chuck A plurality of radially arranged T-slots 18 are uniformly distributed on the periphery of the 1. A slide rail assembly 19 is fixed on the T-slot 18, and the slide rail 6 is installed on the slide rail assembly 19 through sliding fit. The inner end of the slide rail 6 is fixedly connected with the jaws 17 of the power chuck 1 through a fine-tuning mechanism, and synchronously drives the slide rail 6 under the contraction or unfolding action of the plurality of jaws 17; the top of the slide rail 6 is provided with There is a limit structure for limiting the workpiece. By adopting the automatic aligning and clamping device with the above structure, according to the diameter of the workpiece, the power chuck 1 of the appropriate size seri...

Embodiment 2

[0044] The method of using the automatic aligning and clamping device to align and clamp a ring-shaped part includes the following steps:

[0045] Step 1: According to the external dimensions of the workpiece 7, adjust the assembly position of the transition pad 14 on the jaw 17;

[0046] Step 2: After the position adjustment of the transition pad 14 is completed, the slide rail 6 is fixed to the correct position on the transition pad 14 by the cylindrical pin 13;

[0047] Step 3: Fasten the slide rail 6 to the jaw 17 through the screw 12;

[0048] Step 4: According to the different diameter and size ranges of the workpiece 7, the card holder 5 is arranged at the appropriate position of the card slot 20 on the slide rail 6;

[0049] Step 5: Activate the power chuck 1, contract the driving jaws 17 synchronously by the power chuck 1, then drive the slide rail 6 through the jaws 17, drive the card base 5 through the slide rail 6, and then drive the slide rail 6 by a plurality of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com