Non-contact scroll saw guide wheel slot type detector

A non-contact, testing instrument technology, used in instruments, measuring devices, optical testing flaws/defects, etc., can solve the problems of low measurement accuracy and difficult measurement, and achieve heavy load bearing on the table, easy to detect and track, and difficult to measure. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

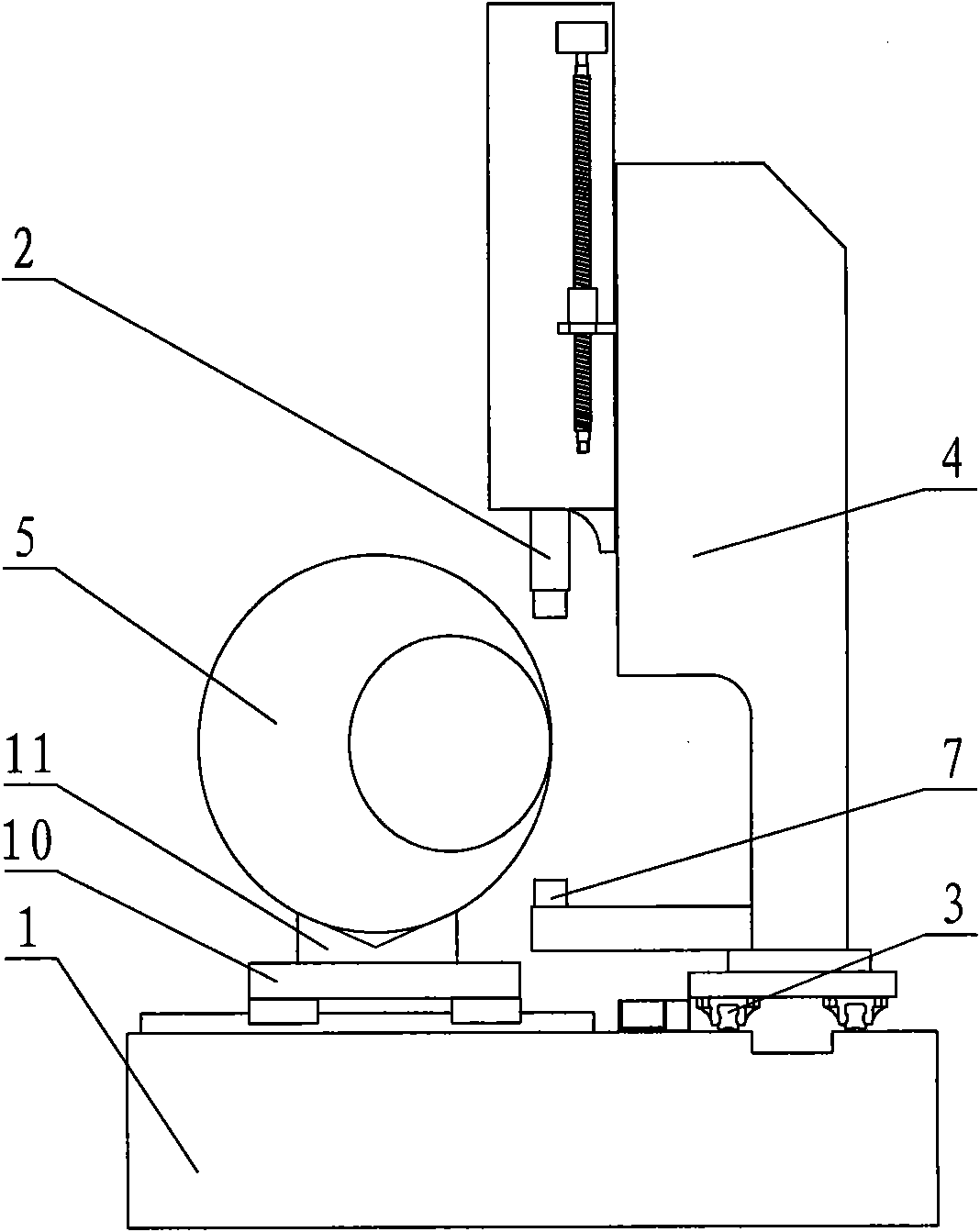

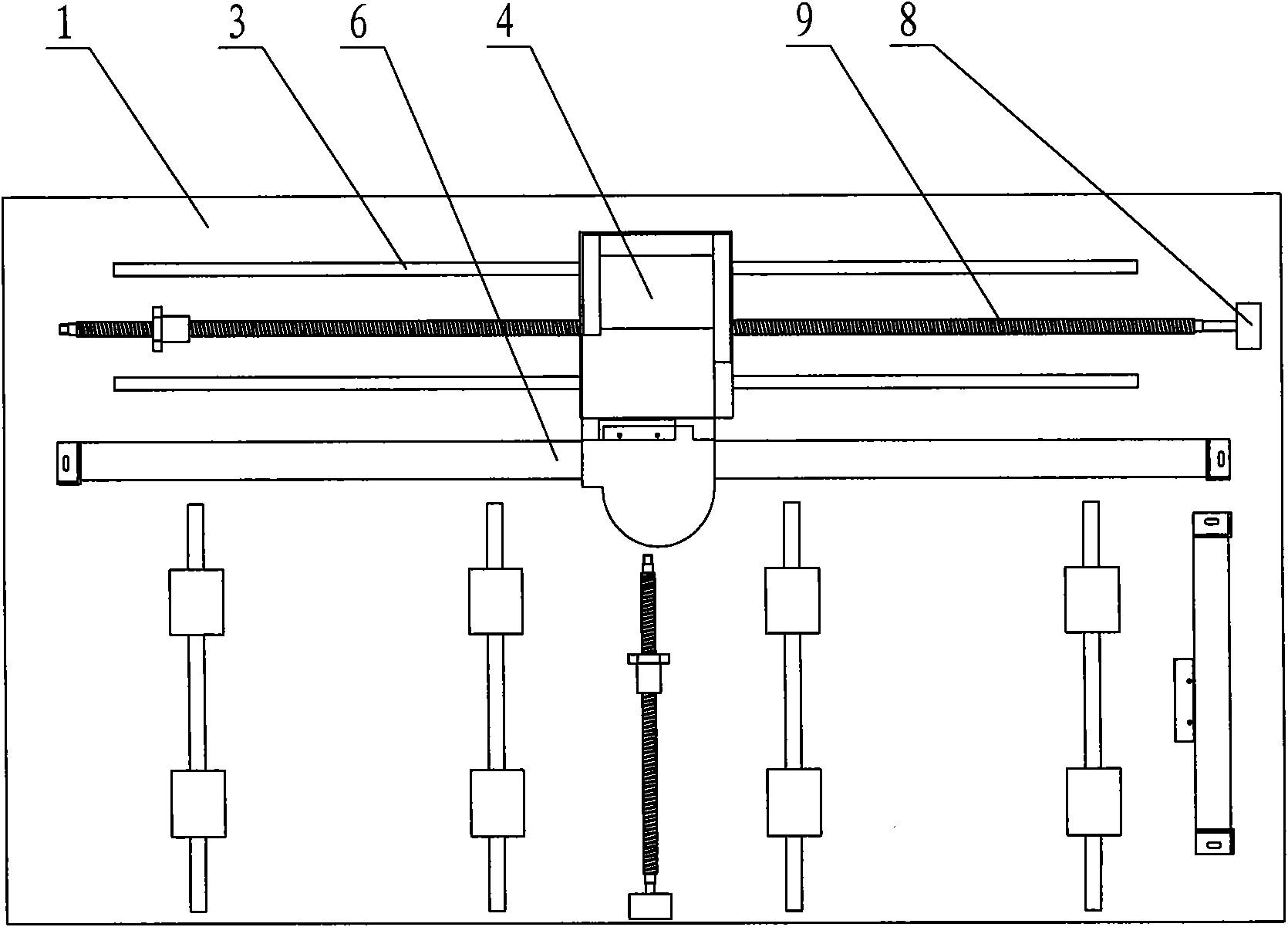

[0018] Such as Figure 1-2 As shown, the high-precision testing instrument for non-contact wire saw guide wheel groove detection according to the present invention includes a base 1 supporting the workpiece to be measured, a CCD imaging lens 2, a high-brightness white LED adjustable light source 7, and an X-axis The Y-axis measures the grating scale 6 and the computer processing element. A CCD imaging lens 2 is arranged on the side of the base body 1 corresponding to the workpiece 5 to be measured. The imaging lens 2 is installed on the guide rail 3 fixed on the base body 1 through the bracket 4 , the direction of the guide rail 3 is parallel to the axis of the workpiece 5 to be measured, and the line formed by the imaging lens 2 and the adjustable light source 7 is tangent to the side of the workpiece 5 to be measured.

[0019] The upper CCD imaging lens 2 and the lower high-brightness white LED adjustable light source 5 are installed on the same movable platform 10, and they...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com