TiNiSn-based Half-Heusler thermoelectric material doped with second phase and preparation method thereof

A technology of thermoelectric materials and raw materials, which is applied in the field of materials, can solve the problems that the shape and size distribution of the in-situ growth of the second phase cannot be effectively controlled, the second phase cannot be effectively regulated, and the process is short, so as to improve the thermoelectric merit value and facilitate The effect of control and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

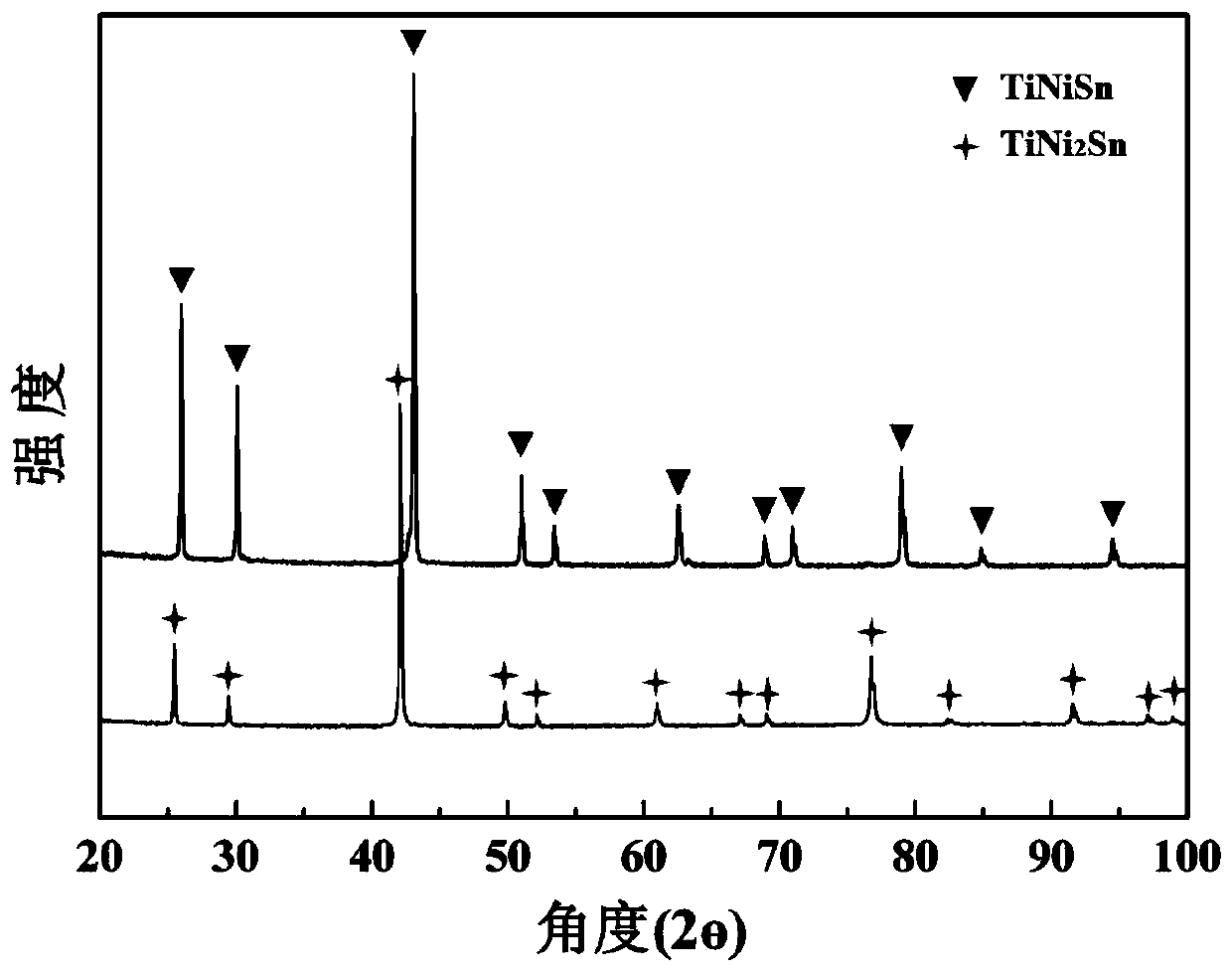

[0039] This example discloses a TiNiSn-based Half-Heusler thermoelectric material with a second phase doping, which is prepared by batching and smelting according to the atomic ratio of 1:1:1 and 1:2:1 respectively. Single-phase TiNiSn and TiNi 2 Sn. Among them, the atomic percentage of each element of TiNiSn is: Ti: 33.3%; Ni: 33.3%; Sn: 33.3%. TiNi 2 The atomic percentages of each element of Sn are: Ti: 25%; Ni: 50%; Sn: 25%. A further improvement of the present invention is:

[0040] The grain size of the TiNiSn base material obtained after ball milling is 0.5-2 μm. TiNi 2 The grain size of the Sn second phase is 1-10 μm.

[0041] A method for processing a TiNiSn-based Half-Heusler thermoelectric material with second-phase doping, comprising the following steps:

[0042] (1) Material selection: Ti, Ni, and Sn select small particles with a diameter x length of 2 x 5 mm. All samples were ≥99.99% pure. The glove box is equipped with TiNiSn and TiNi according to the no...

Embodiment 2

[0058] (1) Material selection: Ti, Ni, and Sn select small particles with a diameter x length of 2 x 5 mm. All samples were ≥99.99% pure. The glove box is equipped with TiNiSn and TiNi according to the nominal composition of the atomic ratio of 1:1:1 and 1:2:1 respectively 2 Raw materials required for Sn.

[0059] (2) Melting: Using a magnetic levitation melting furnace, under an argon protective atmosphere (10 4 -10 5 Pa), heat up to 1600-1800°C and keep warm for 4 minutes. In order to ensure the uniformity of the structure after smelting, repeat smelting 5 times.

[0060] (3) Ball milling of TiNiSn: first, use a mortar to roughly grind the ingot into a powder with a particle size of 0.1-1 mm. Then wet ball milling was performed under an argon atmosphere. The ball milling medium is absolute ethanol, the ball-to-material ratio is 20:1, the rotational speed is 600r / min, and the ball milling time is 8h.

[0061] (4) Ball milled TiNi 2 Sn: first use a mortar to roughly gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com