Non-core-plate bearing vehicle body deflection forming method

A car body, non-centre technology, applied in the field of deflection forming of non-centre disc bearing car body, can solve the problem of difficulty in deflection forming, and achieve the effects of shortening production cycle, improving production efficiency and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

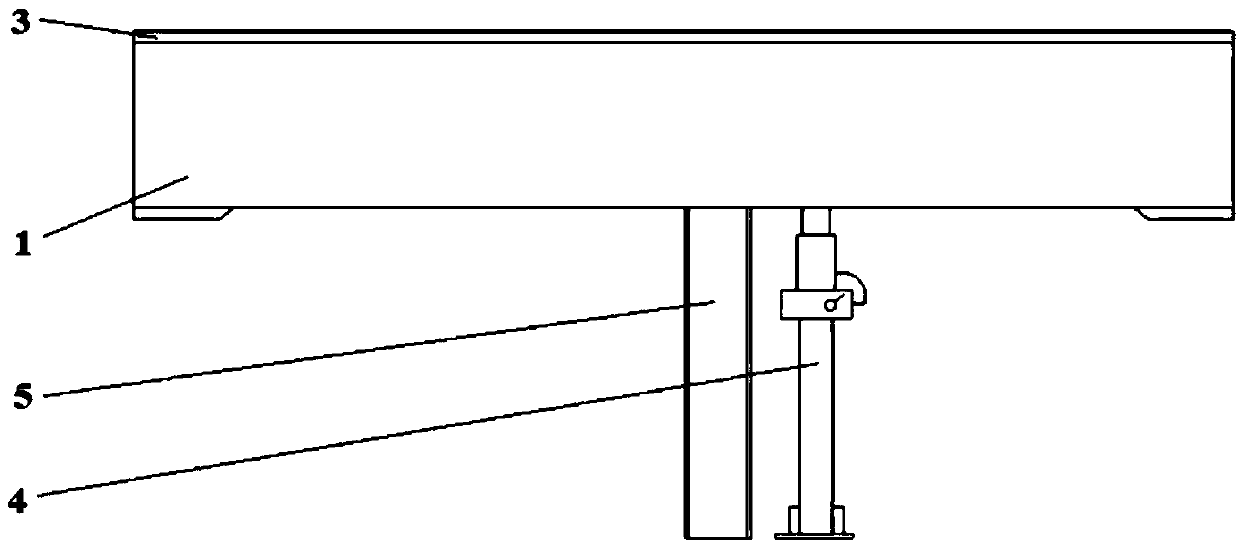

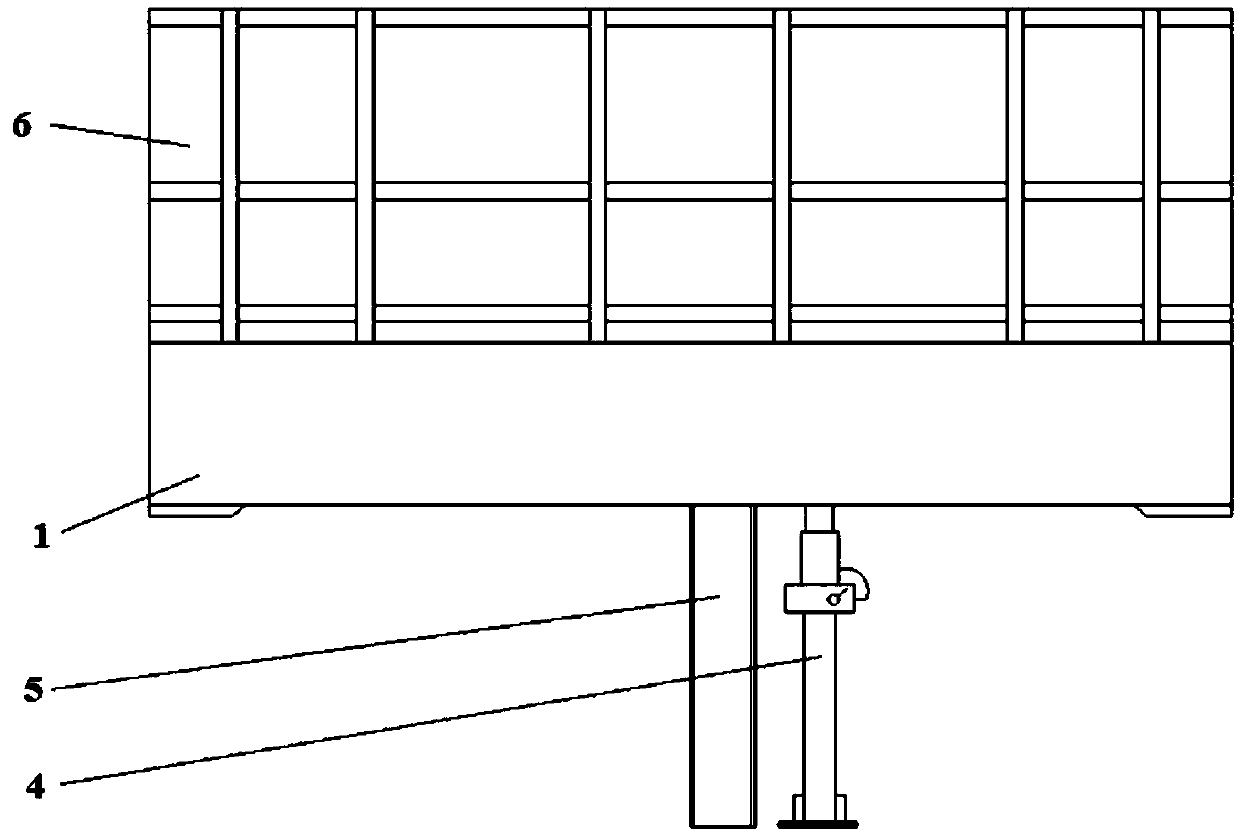

[0032] This embodiment provides a deflection forming method for a non-center-disk bearing vehicle body. The method uses multiple pre-deflections to deflect the center sill and side beams between the two bolsters of the non-center-disk bearing vehicle body by 2-12 mm.

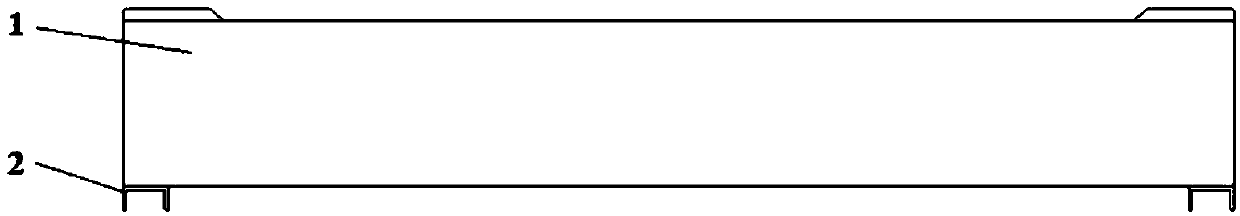

[0033] In this embodiment, the non-center disc bearing vehicle body includes: a vehicle frame, an upper body mounted on the vehicle frame, the vehicle frame includes a center beam, side beams and an iron floor, and a skin is welded on the upper body.

[0034] In this method, pre-bending is carried out in the steps of laying the iron floor, joining the vehicle frame and upper body, and skinning.

[0035] Specifically, the method includes the following steps:

[0036] Step 1: After the front assembly and welding of the frame are completed, the frame is turned over, and the opposite side of the channel steel is welded on both ends of the frame;

[0037] Step 2: After the frame is welded and before the iron floor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com