Process for integrally forming cloth and patterns through silica gel

A silica gel and process technology, applied in the field of silica gel integrated molding cloth and pattern process, can solve the problems of high printing production cost, low production efficiency, low efficiency, etc., and achieve the effect of saving production cost, saving production cycle and perfect combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

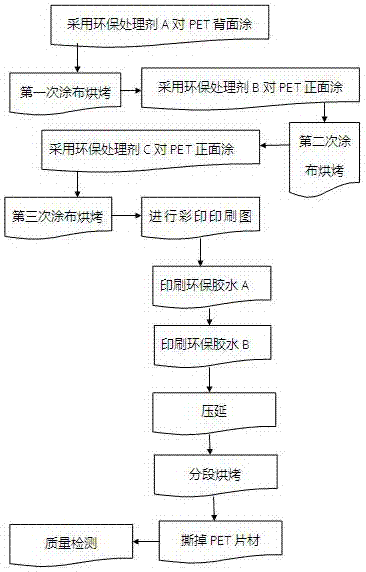

Method used

Image

Examples

Embodiment 1

[0052]Environmentally friendly treatment agent A is used to coat the back of PET, and the thickness of the coating on the back of PET is 1.5 μm. The components of the environmentally friendly treatment agent A by mass percentage are: 3% coupling agent, 5% electrostatic agent, and 2% curing agent. , the balance is methyl vinyl; for the first coating and baking, the coating speed during baking is 50m / min, and the baking temperature for the first coating is 115°C / 15min; environmental protection treatment agent B is used to treat the front side of PET Coating, the thickness of the coating on the front side of PET is 1.5 μm, and the composition of the environmental protection treatment agent B by mass percentage is: coupling agent 5%, retarder 8%, curing agent 7%, and the balance is methyl vinyl ;For the second coating and baking, the coating speed during baking is 20m / min, and the baking temperature for the second coating is 115°C / 15min; the front side of PET is coated with environ...

Embodiment 2

[0055] Adopt environmental protection treatment agent A to PET backside coating, the coating thickness that PET backside is coated with is 2 μ m, and the component by mass percentage of described environmental protection treatment agent A is: coupling agent 3%, electrostatic agent 5%, curing agent 2%, The balance is methyl vinyl; for the first coating and baking, the coating speed during baking is 50m / min, and the baking temperature for the first coating is 120°C / 15min; use environmental protection treatment agent B to coat the front side of PET , the thickness of the coating on the front side of PET is 2 μm, and the components of the environmental protection treatment agent B by mass percentage are: 5% coupling agent, 8% retarder, 7% curing agent, and the balance is methyl vinyl; The second coating is baked, the coating speed is 20m / min during baking, and the second coating baking temperature is 120°C / 15min; use the environmental protection treatment agent C to coat the PET fr...

Embodiment 3

[0058] Environmentally friendly treatment agent A is used to coat the back of PET, and the thickness of the coating on the back of PET is 2.5 μm. The components of the environmentally friendly treatment agent A by mass percentage are: coupling agent 3%, electrostatic agent 5%, curing agent 2% , the balance is methyl vinyl; for the first coating and baking, the coating speed during baking is 50m / min, and the baking temperature for the first coating is 150°C / 15min; the environmental protection treatment agent B is used to treat the front side of PET Coating, the thickness of the coating on the front side of PET is 2.5 μm, and the composition of the environmental protection treatment agent B by mass percentage is: coupling agent 5%, retarder 8%, curing agent 7%, and the balance is methyl vinyl ;For the second coating and baking, the coating speed during baking is 20m / min, and the baking temperature for the second coating is 120°C / 15min; the front side of PET is coated with environ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com