Convenient horizontal rotating device

A horizontally rotating and convenient technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficult shear ring plate and cylinder horizontal submerged arc welding, high labor intensity of welders, low welding efficiency, etc. , to achieve the effects of saving production cost and production cycle, improving labor safety and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

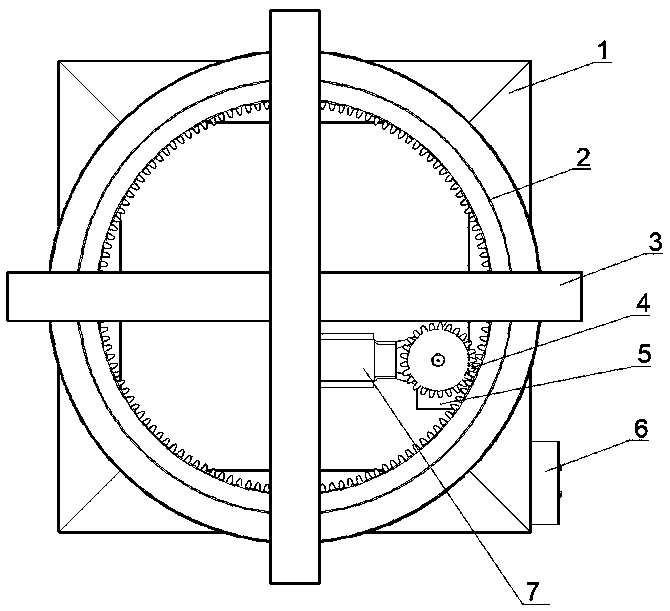

[0022] Such as figure 1 As shown, the motor 7 is fixed on the bottom platform 1 through the safety fixing device 5, the motor 7 is connected to the gear transmission system 4, the equipment bracket 3 is fixed to the gear transmission system 4 by welding, and the ball rotation system 2 is fixed to the bottom platform 1 by welding , The motor 7 is powered through the switch box 6 to provide power for the whole system.

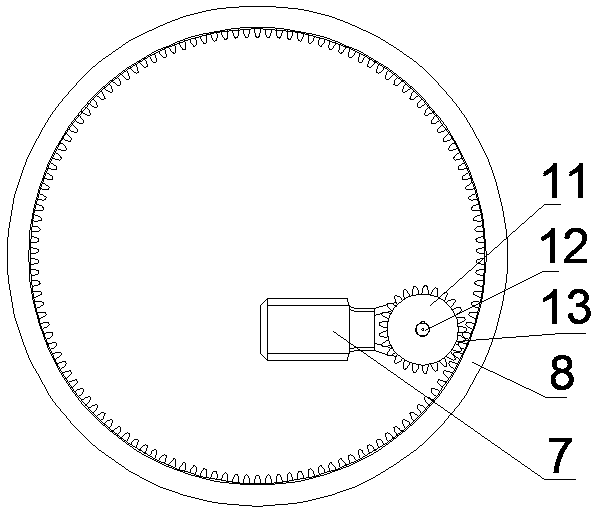

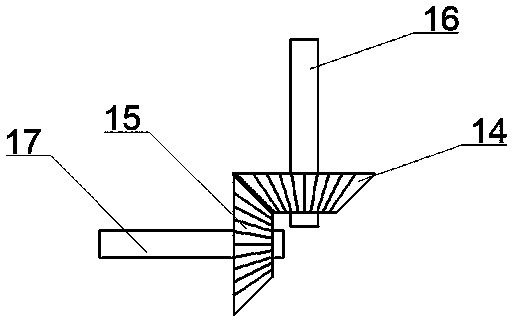

[0023] Such as figure 2 As shown, the gear transmission system 4 provides power through the motor 7 to drive the gear vertical transmission system 12 to change direction. 8 to make the device rotate at a variable speed in the horizontal direction. Considering that the welding speed of submerged arc welding should not be too fast, the ratio of gears should be considered when meshing with gears, and the welding speed should be controlled betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com