Forming method and die of anisotropic annular magnet

A ring magnet and anisotropic technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as waste of resources, increased resistance to thermal deformation, and growth of nanoscale grains, and achieve savings The effect of production cost and production cycle, improvement of production efficiency and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

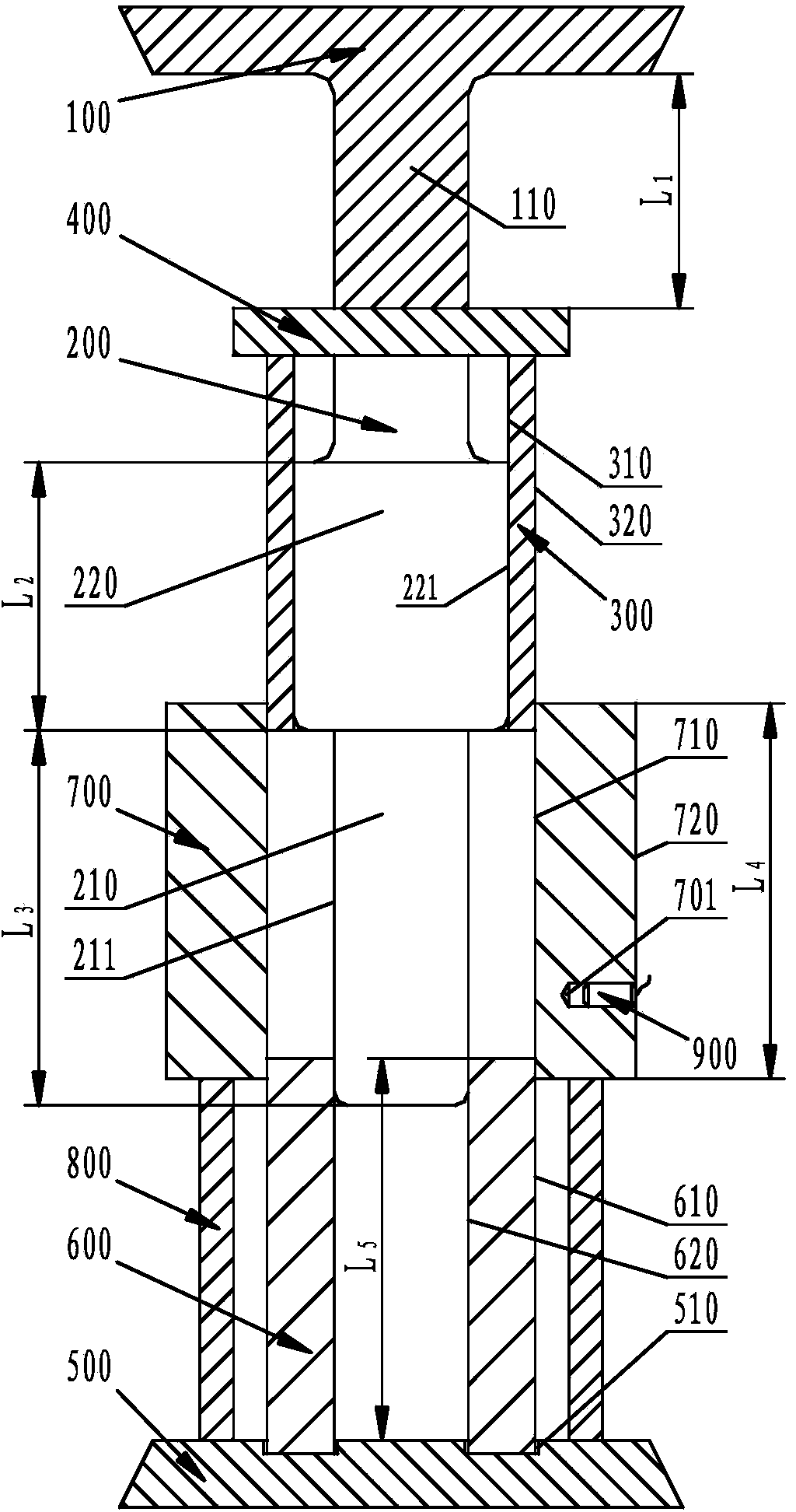

[0086] Now it is necessary to manufacture an anisotropic ring magnet with an outer diameter of 40mm, a thickness of 4mm, and a height of 40mm.

[0087] Firstly, according to the size requirements of the anisotropic ring magnet, the mold of the anisotropic ring magnet of the present invention is designed, and each part of the mold of the anisotropic ring magnet is made of cemented carbide with a brand name of YS2T.

[0088] Then, the forming method of the anisotropic ring magnet is as follows:

[0089] Step A, the inner wall 710 of the annular die of the mold of the anisotropic ring magnet is provided with a layer of graphite paper with a thickness of 0.38mm, the outer wall and the inner wall of the punch 300 on the ring of the mold, and the inner wall of the mold. The outer wall 211 of the mold core with the upper punch of the mold core is coated with a layer of graphite emulsion;

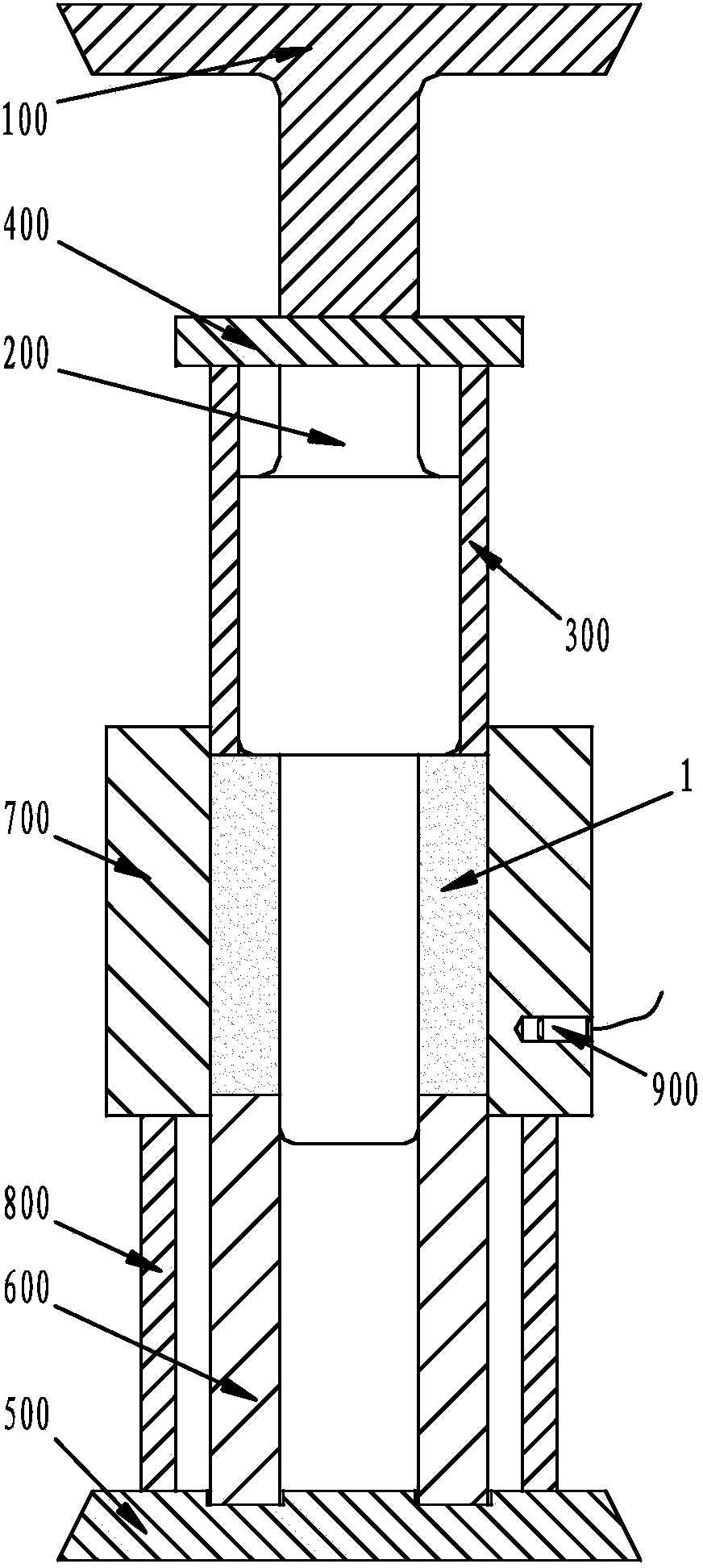

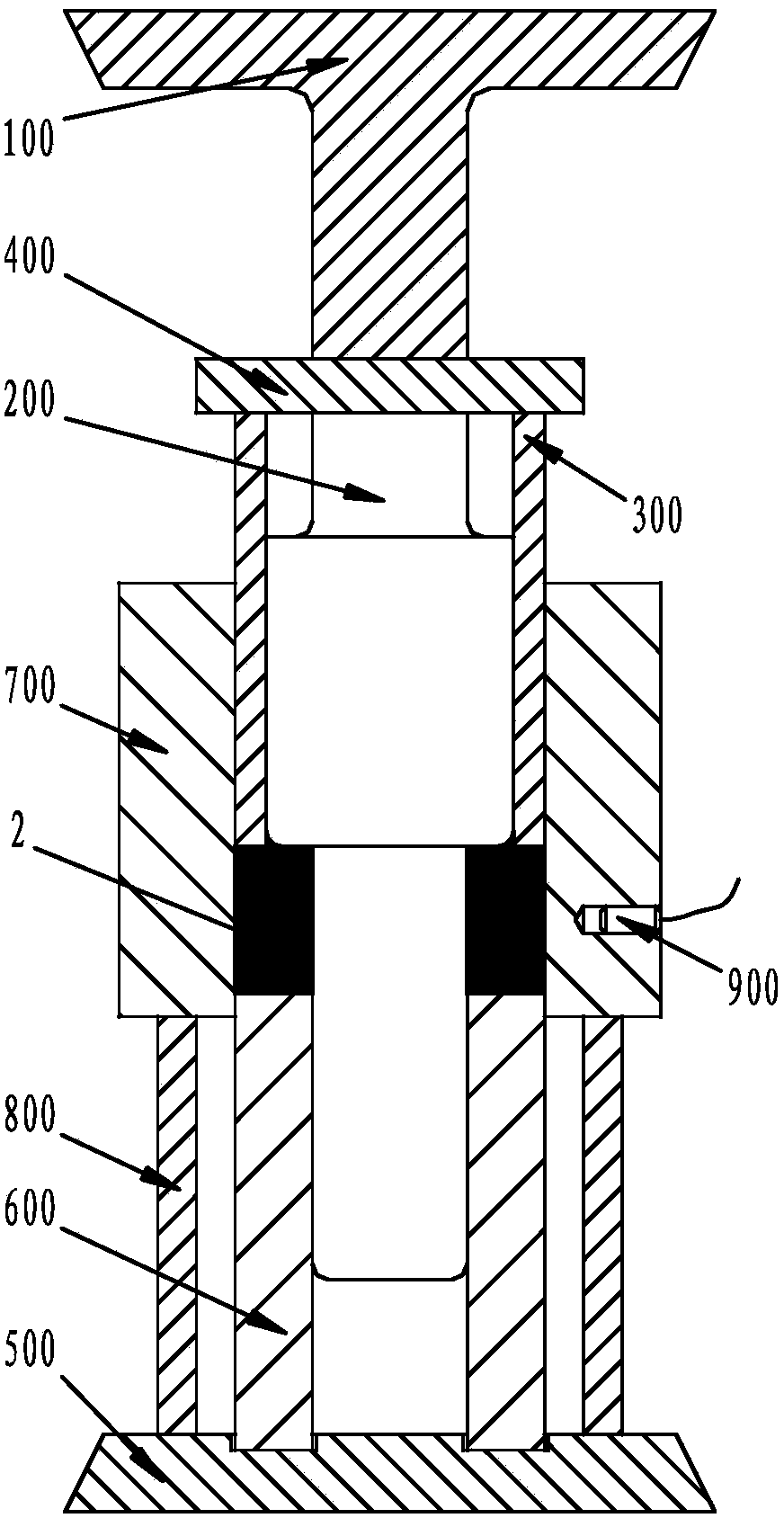

[0090] Such as figure 2 As shown, weigh 137.5g of rare earth iron-based magnetic powder 1 (u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com